Worm Screw Jack made in china

Keyword:Screw Jack Time:2019-10-19 21:49:54

Product Introduction

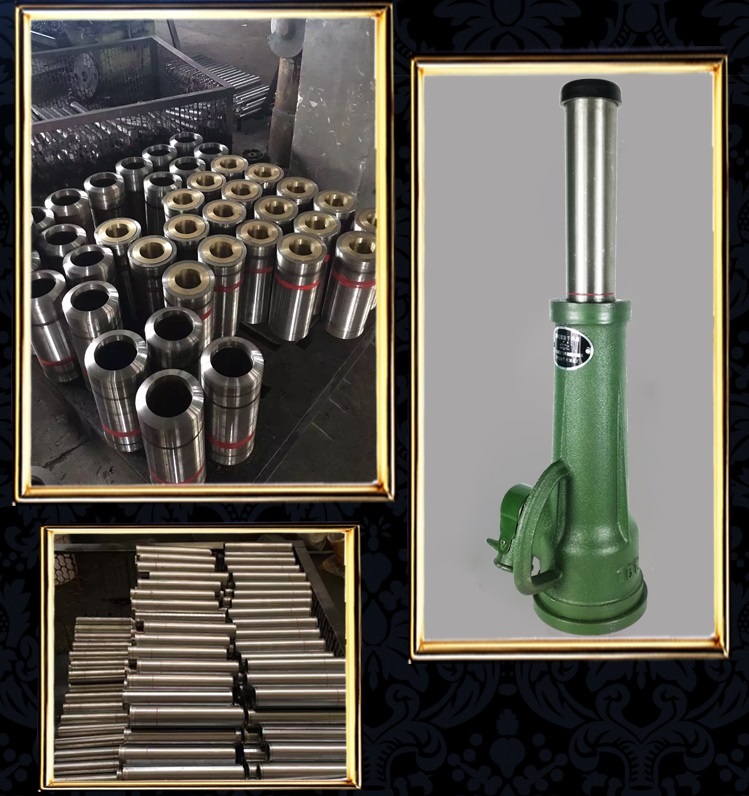

The internal nuts that fit the screws are made of copper alloys, making the jack safer and more reliable with longer service life through their high mechnical properties and good lubricating performance.

Lifting Jack is one kind of lifting tools. Spiral jack aka screw jack, mechanical jack, ratchet jack, hoisting jack, lifting jack, screw bottle jack, machine screw jack etc. Screw Jack is suitable for general engineering applications. Body and cap is made of graded cast iron, screw is made of steel, threads are machine cut - square threads and has a serrated swivelling cap. The jack is available with either ratchet arrangement or plain four way head suitable for operation with ratchet or tomy bar respectively. Screw jack application: factory ware house, bridge construction, shipyard, engineering construction and other department of lifting operation.

Details

1.Helical Jack cover, wear-resistant alloy steel material, formed by cast iron, forging and manufacturing, top cover.

2.The screw jack is made of high strength copper compound. High precision, wear resistance, great ductility with stability.

3.Jack with integral casting and integral forming body, abrasion resistance and adaptability have all been greatly improved.

4.The base and ratchet of the screw top are made of precise steel, quenched at high frequency and high temperature.

Usage

(1) Before lifting heavy objects, pay attention to the position of the jack to keep it vertical so as to prevent the screw from deflecting and bending and the accidents caused thereby.

(2) When the top weight is heavy, the handle shall be evenly shaken by force to avoid accidents and damage to jacks caused by up-and-down impact.

(3) When in use, care should be taken not to exceed the allowable maximum jacking capacity to prevent accidents caused by overload.

(4) When in use, the jacking height shall not exceed the mark line on the sleeve or piston. For jack without mark line, the jacking height shall not exceed 3/4 of the total height of screw thread or oil plug, so as not to take off the sleeve or piston top and damage the jack and cause accidents.

(5) Before loosening the jack to make the weight fall, it is necessary to check whether the weight has been firmly supported, and then slowly drop it to ensure safety.

(6) During use and storage, grease shall be used to prevent excessive wear and reduce service life.

Application