2 3 4 Legs Alloy Steel Chain Lifting Sling made in china

Keyword:Chain Slings Time:2019-4-28 23:46:24

Adjustable chain slings made in china

Quick Details

Material: Alloy, steel

Size: 1/4"-7/8"

Lifting Capacity: 0.5t-32t

Shape: Round

Structure: Combined Chain, Welded Chain

Process: Froged, Qunenched and Tempered

Surface: Powder Coated, Painted, Zinc, HDG

Technology: Forged Galvanized Shackle

Packing: Drum, Pallet or other

Packing: Drum, Pallet or other

Safety factor: 4 times

Color: As According to Requirements, Red, Yellow or other

Function: Hardware, Lashing, Lifting, Transmission Chain, Lifting and Sling

Samples: Can Be Supplied

Business Type: Manufacturer And Exporter

Keywords: Chain Sling

Introduction:

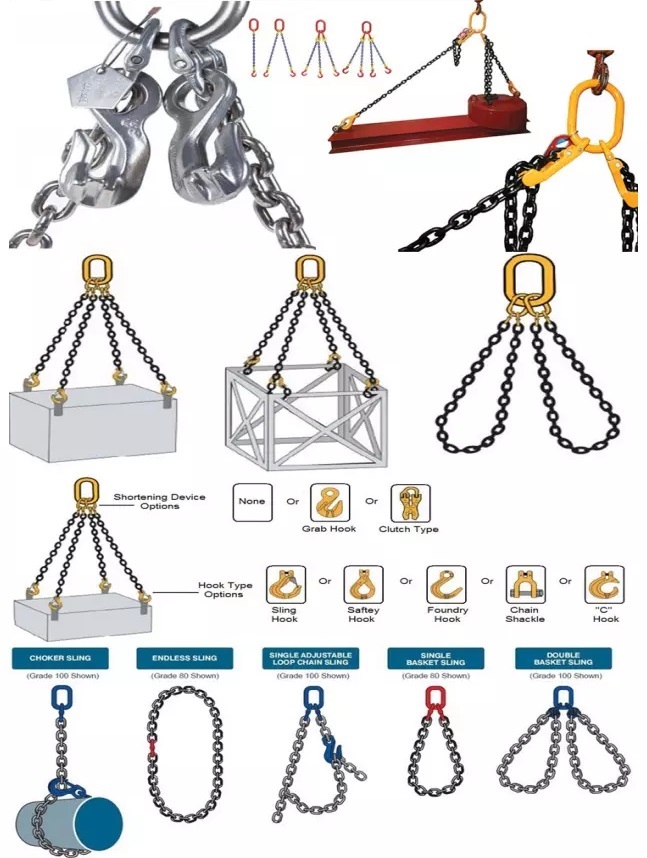

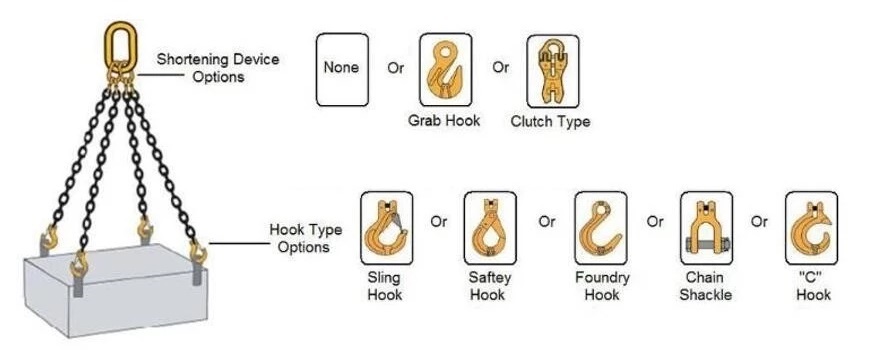

Grade80 Lashing Chain Sling With Sling Hook is the most common type of sling used in lifting and rigging. Chain slings are made up of lengths of high tensile chain, with a variety of high tensile components attached. Shortening hooks are available on any type of chain sling, meaning one chain sling can be purchased and shortened for use at different engths. They are used for lifting heavy items on construction sites such as: skip bins, concrete slabs, pipes, building materials etc.

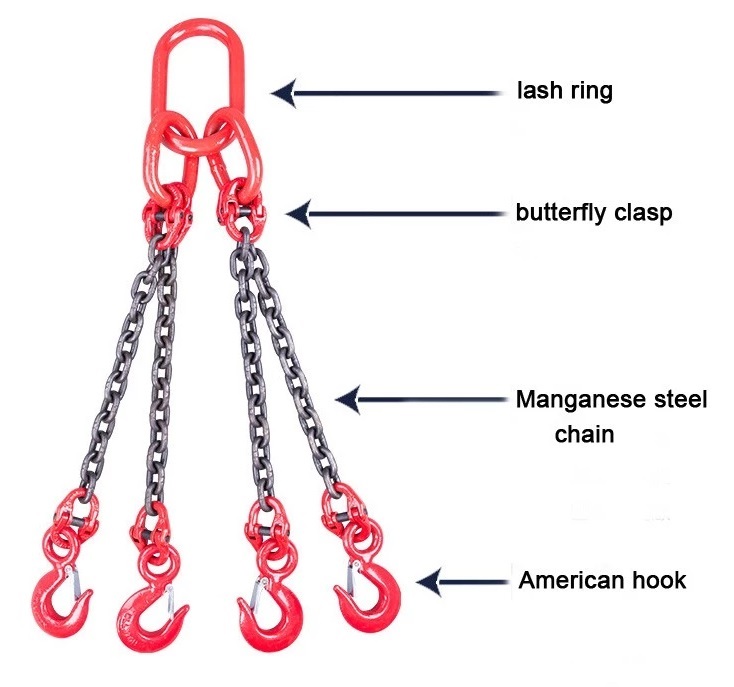

Chain slings are available in one, two, three and four leg configurations, which are available in lengths from 0.5 meters to 10 or more meters. Chain and components range in sizes from 6mm – 20mm. There are various components available to make up the chain sling, including: head rings or oblong links, couplers or hammerlocks, self-locking hooks, sling hooks, and shortening hooks. Contact RAMHOIST directly to learn more about how to make a chain sling.

It is important to consult a working load limit chart regarding angle factors when using a chain sling. The angle at which a load is slung can affect the working load limit of a chain. The wider the angle at which a chain sling around a load, the more decrease in the working load limit of that chain. The most efficient angle to sling a load is at 60 degrees.

CAUTION: All slings are sold with the package understanding that the purchaser and/or user are thoroughly familiar with their proper use. Do NOT use Breaking Strength for design or rating purposes. Use Working Load Limit instead. It assumes no responsibility for the use, misuse or misapplication of its products.

Product Description

1, The chain riggings are made up of G80 rigging parts and G80 chains

2, The chain rigging includes four types: Single leg, double legs, three legs and four legs. We are able to produce all kinds of chain slings as per your requirements

3, High quality, large quantity, low price and on-time delivery

4, High temperature-resistance, durable and easy to install.

5, The outstanding advantage is to resist abrasion, high temperature and corrosion, and has the feature of low elongation.

6, Widely used in steel factories, steel pipe factories, petrol pipe installing factories and other enterprises.

Chain sling safety

-

Always use within posted working load limit

-

Distribute loads evenly; an unequal load on one leg can create a dangerous situation and damage the sling

-

Rapid or sudden stops, impacts, and lifts should be avoided

-

Protect sharp edges and corners accordingly with padding or protectors to keep chain from coming in contact

-

Clean chains prior to inspection; oil and dirt can hide chain damage

-

Load hooks should never be tipped or pointed; a latch should never support a load

-

Do not allow a chain length to be twisted or tied into a knot

-

Do not use slings with damaged, defective, or worn chain

-

Don't forget to inspect hooks- never use if bent or distorted in any way

Application:

Different Hooks:

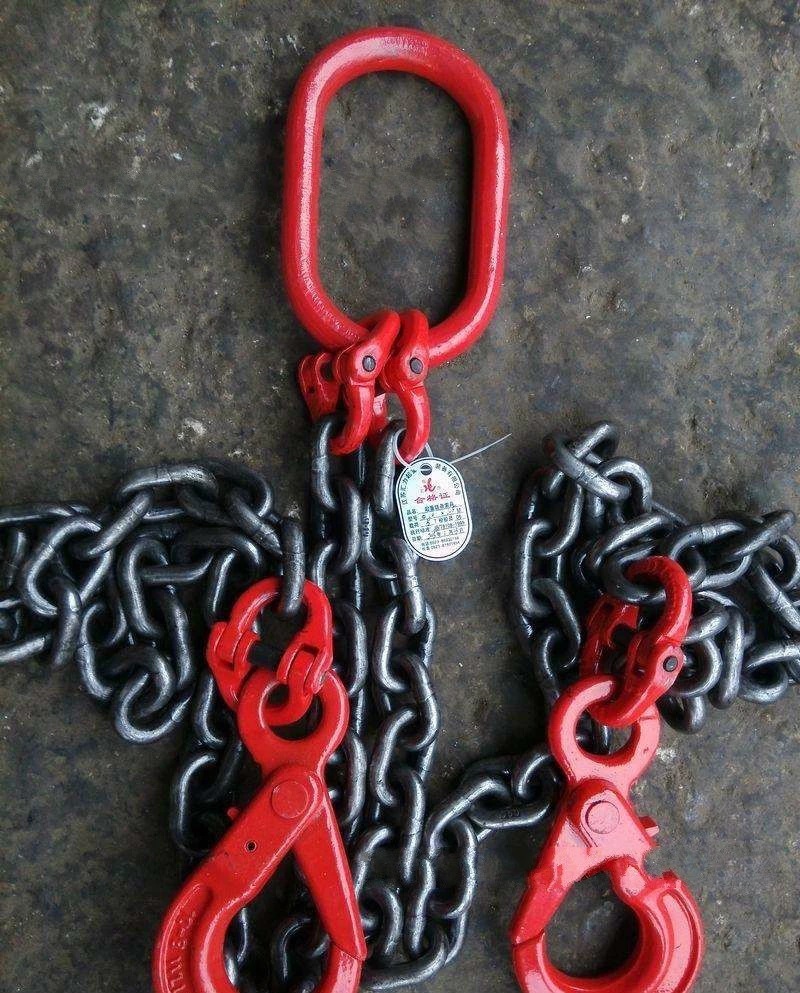

Site Photos of chain sling

Package: