High Quality 1t to 5t Vertical Steel Plate Lifting Clamp

Keyword:Lifting Clamps Time:2019-4-30 16:09:41

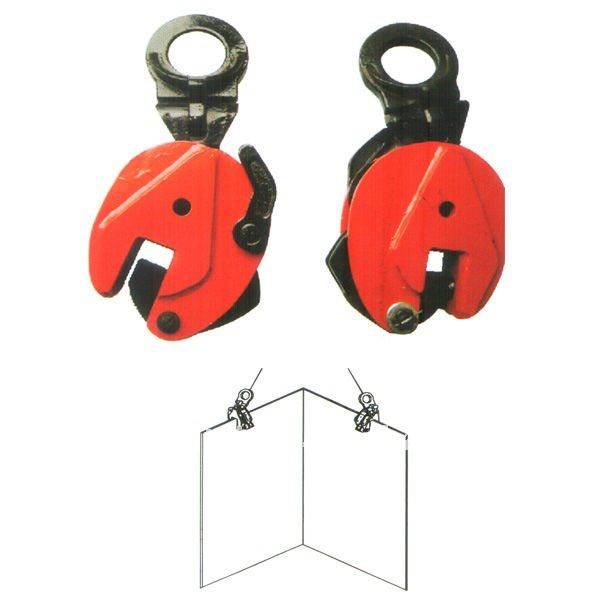

Vertical plate lifting clamp

Product description:

The plate lifting clamps are suitable for the lifting, turning and transporting of plates with sensitive surfaces without leaving behind indentations. It is especially suited for aluminum and stainless steel plate or those with extremely hard surfaces.

The surface of the plate must be free of oil, grease, or any other liquid to ensure safe transport.

Heavy-duty plate clamps are designed to vertically lift and turn plate material. These lifting clamps include a pivoting bail for versatile, smooth operation and automatic serrated hardened steel pads and cams. Clamps feature a drop-forged steel case for maximum strength. Meets ASME B30.20 specifications.

Plate lifting clamps are mechanically operated for smooth, fast and safe handling of plates both horizontally and vertically. These clamps will hold the plates with a friction gripping force, which can be locked through a lever, while holding the plate. Till the lever is unlocked, the plates are not released. They are very safe for handling of plates, with minimum manpower.

• For lifting and transporting of thick steel plates

• Articulated lifting shackle

• The clamp is fitted with a locking device for both open and closed positions, which ensures complete safety

• The clamp is locked in closed as well as in open position

• Manufactured from high quality carbon steel

Features:

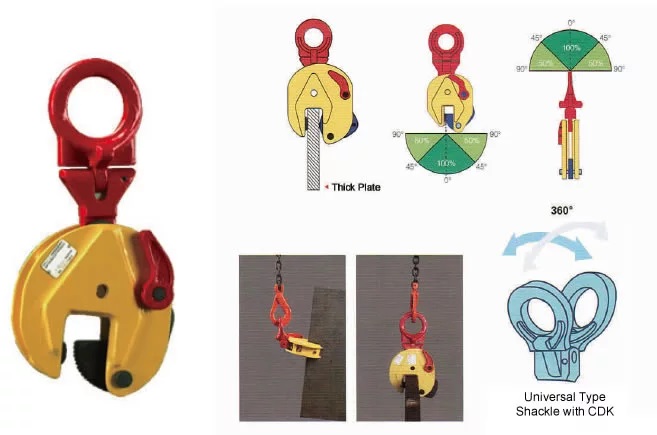

The Universal vertical PLC clamp is designed to ensure that the load can be lifted and turned (180°). Whilst at the same time ensuring that the Load is positively retained.

These clamps have a wide range of uses and are particularly suited for the lifting and turning of steel plates, ship sections and the extraction of pile sheets.

Fitted with a hinged hoisting eye moving in all directions so as to enable the user to place and lift the load from any directions.

Clamps are fitted with special hook-up facilities to enable easy fitment of the clamp in horizontal position.

The new models have a greater jaw aperture enabling plates of varying thickness to be lifting with the same clamp.

The clamp is fitted with a safety latch which ensures the proper use by means of a double locking device, both in open as well as closed position.

This also guarantee a preload on the material being lifted.

The clamps are suitable for surface harnesses up to 37Rc(245HB). Small overall dimension with a relatively high lifting capacity.

Overall forged structure with good trace ability and the safety factor of 6 times.

Details:

Forged Clamp Body

Material: High Quality Steel

These lifting clamps come with high quality material, to guarantee the working performance well during the working condition

Process: Forged overall & casting

We have stronger one, forged over all body. Some types are also with casting parts. That depends on different customers' requirements.

Tightly Connected with Each Spare Parts

Each clamp parts was processed in accurate tolerance, and assembled with each stronger.

Stronger Springs

The spring assembling for lifting clamps is made with high quality spring wire, which can stand larger breaking strength.

Different clamps Handle

Vertical type clamps handle

Horizontal type clamps handle

Universal type clamps handle

Turnover type clamps handle

Working Instruction Advice:

Lifting clamps are equipped with a per-tension mechanism ensuring the clamp does not slip when lifting force is applied and when load is being lowered. The clamp is locked in closed as well as in open position. Minimum WLL is 10% of the maximum WLL

Note: The plate surface of the material must have hardness lever below

Trips:

.DO NOT side load clamp more than 15 degrees for side loading

.DO NOT lift plates with a temperature greater than 100 degrees

.DO NOT use to lift stainless steel, lead or copper.

.DO NOT use on a double, triple, or quad sling. When using two clamps to lift a steel plate, a lifting beam must be used between the two clamps, so the clamps operate in a vertical position.