Vacuum tube lifter/Tube Vaccum Lifter for wooden panel,sheet metal,steel boards

Keyword:Vacuum tube lifters Time:2019-5-10 16:49:22

Product Description

With the high development of modern high-tech power, more and more advanced technologies have been applied to logistics activities, and one of the relevant important applications is the transport manipulator. Pneumatic manipulator, as a kind of manipulator, is widely used because of its advantages including simple structure, light weight, fast movement, stable, reliable, energy saving and environmental protection

The carrying manipulator usually has the following three characteristics:

1.The pins can be designed with pneumatic or mechanical clamps and vacuum suckers.

2.Each arm is individually designed for practical use. The metal body of the manipulator is suitable for various industrial applications.

3.Watch moves, lifts and clamps by PLC or industrial computer to complete a set task.

Products advantage:

1, Solely pneumatic, lower noise, easy operation, flexibility

2, A ball bearing integrated upper rotation jointer with single way valve to prevent the goods falling down in case of power lost.

3, It allows a fast presetting of the load balancing effect in case of weight change.

4, It allows the lifting and handling of the load in a quick, precise and linear way, without any adjustments, simply moving a lever control.

5,Two-hands control unit with a rotation handle for up and down, the brake handle for release, the handle were extended for higher stack

6, It allows the load balancing by moving a pneumatic push button after lifting the load through a lever control.

7, It allows automatic load balancing without any adjustment, after having simply moving the gripping through proper controls.

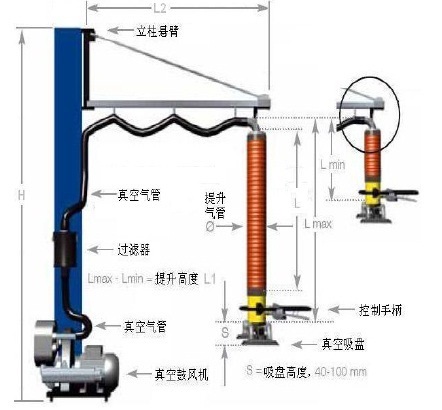

8, A plastic vacuum filter mounted on the column.

9, A vacuum regulator mounted on the vacuum blower which protect the blower in case overheat, the preset vacuum pressure is -45kpa

10, 8M vacuum feeding pipe of Diameter 52mm for vacuum connection

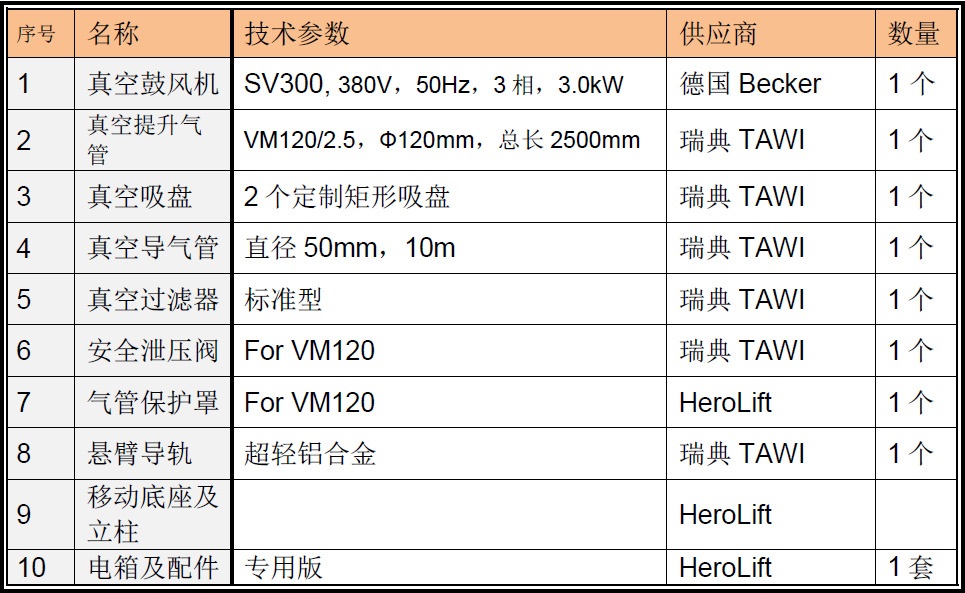

Main components:

1. Vacuum blower: Siemens vacuum blower, model GS3.0, power supply 380V, 3.0KW, maximum vacuum flow 150cbm/h, maximum vacuum pressure -55kpa

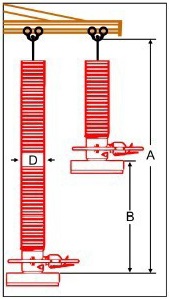

2. Lifting tube: diameter 180mm, tube length 2550mm, maximum lifting height 1650mm, maximum loading 80kg for semi-porous, 90kg for dense.

3. Six of round bellow suction pads for carton box, pads diameter 125mm, the yoke length 800mm,width 400mm, mounted on the control housing by flange

4. An electric control box mounted on the ground (column installation available for option)

The lifter was designed for transportation or handling the materials at: 90kg for dense materials, 80kg for semi-porous materials

Application of vacuum tube lifters

Fast and frequent lifting and moving of workpieces weighing up to 300 kg, for example:

Handling goods such as cardboard boxes, bags, barrels, buckets and jugs within in-house logistics processes

Loading and unloading CNC machining centers

Benefits of of vacuum tube lifters

Increase productivity thanks to reduced handling and loading times

Secure, damage-free gripping by using vacuum

Minimization of downtime due to employee injury

Increase in employee motivation

Only one person for handling

Details of Vacuum lifters

Sacks made from a wide range of materials are handled during the manufacture of tires. Particularly In mixing areas, sacks may be made from paper or plastic and can be perforated or sealed.

The RAMHOIST tube lifter can be operated with just one hand. As a result, it lets you handle sacks in a simple and ergonomic way. The grippers can be adapted to a huge variety of materials and therefore provides maximum flexibility.

Special glass suction cups prevent any marks on the workpieces. RAMHOIST lets you rapidly handle up to 300 picks per hour.

Our vacuum tube lifters are in conformity with the European Machinery Directive. Before shipped, each lifting device receives an individual inspection, a CE mark, a CE Declaration of Conformity or a CE Declaration of Incorporation, and technical documentation.