Durable Frp Pultrusion Profile Anti-Uv Pultruded Fiberglass Square Tube

Keyword:Pultrusion Tubes Time:2019-6-17 23:48:23

Pultrusion frp square tube, pultrusion grp square tube, pultrusion fibeglass square tube, pultrusion glass fiber square tube

| Item | FRP tube |

Material | ECR Glass Fiber+Resin+Filling |

Size | Customized |

Color | Yellow, orange, Blue, Green, Grey, etc. can be customized |

Anti-Corrosion | No rust, resistance to acid, alkali, organic dis-solvent and other gas and liquid mixture. |

Anti-skid / slip | Different process mode on surface, concave, gritted, increase friction factor. |

Anti-aging | Have more than 20 years effective service life under normal outdoor working condition. |

Anti-fatigue | Moderate flexibility reduces the workers` pressure on legs and waist. |

Easy maintenance | Have alternative and bright colors. Non-fading. Easily for clean. |

Excellent economic benefits | Excellent comprehensive economic benefits |

Forming Way | Pultrusion |

Resin Type Ortho, IFR or VE

Surface Treatment Mat surface or smooth

Fire test Anti fire

UV test Anti UV

Product Name: Square Hollow Steel Tube/Square Pipe/frp square tube

Tensile strength 600-1200Mpa

Density 2.2g/cm3

Length Customized Length

Usage Construction, chemical industry, Industrial, Household, Civil special area, Tunnel

HS Code 7019909000

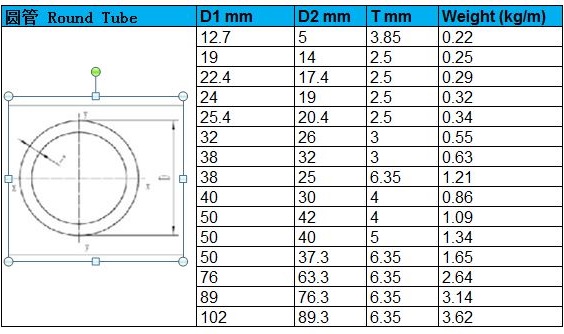

The different size of our round tubes

FRP Pultrusion information

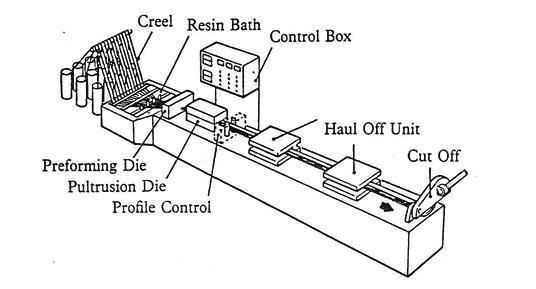

Pultrusion is a continuous process for the manufacture of products having a constant cross section, such as rod stock, structural shapes, beams, channels, pipe, tubing, fishing rods, and golf club shafts. Pultrusion produces profiles with extremely high fiber loading, thus pultruded products have high structural properties.

Pultrusion is a manufacturing process for producing continuous lengths of FRP structural shapes. Raw materials include a liquid resin mixture (containing resin, fillers and specialized additives) and reinforcing fibers. The process involves pulling these raw materials (rather than pushing as is the case in extrusion) through a heated steel forming die using a continuous pulling device. The reinforcement materials are in continuous forms such as rolls of fiberglass mat or doffs of fiberglass roving. As the reinforcements are saturated with the resin mixture ("wet-out") in the resin impregnator and pulled through the die, the gelation (or hardening) of the resin is initiated by the heat from the die and a rigid, cured profile is formed that corresponds to the shape of the die.

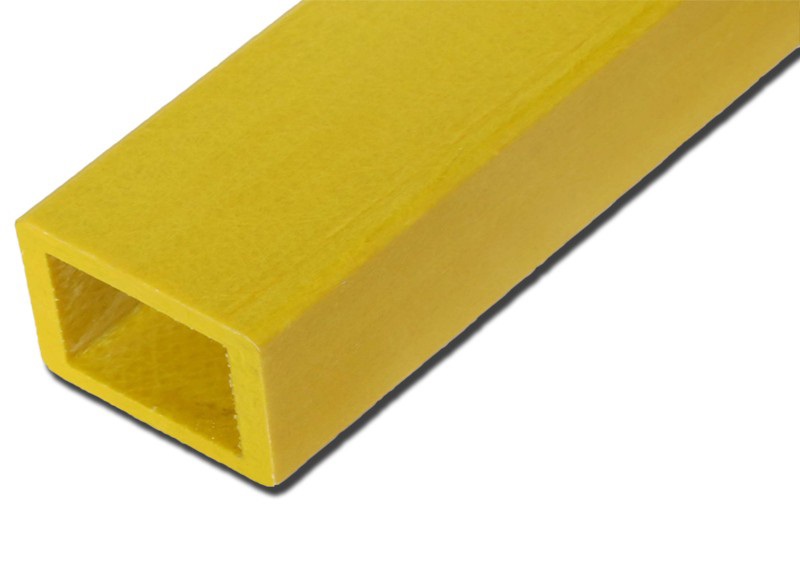

Product Description of the FRP square tube

Fibreglass pultruded profiles are manufactured by combining various resins with pure glassfibre reinforcement. They are formed and cured in a continuous process creating a product of extraordinary strength and resilience. The resultant fibreglass pultruded profiles offer a combination of benefits and mechanical properties exceeding those of metal. Manufactured from pultruded fibreglass profiles and can be supplied in channel, I-beam, box, angle and tube sections for the construction of chemical resistant plant assemblies. The materials are often used to fabricate stairs, access platforms, step over platforms and ramps

Pultruded FRP profiles are with constant cross-section structure by a conitnuous pultrusion process using fiberglass reinforcements with thermosetting resin matrixes. Pre-selected reinforcement materials, such as fiberglass roving, mat, woven fabrics, are drawn through a resin bath in which all materials are thoroughly impregnated with a liquid thermosetting resin. Typical resins included polyester, vinyl esters and phenolic resin.

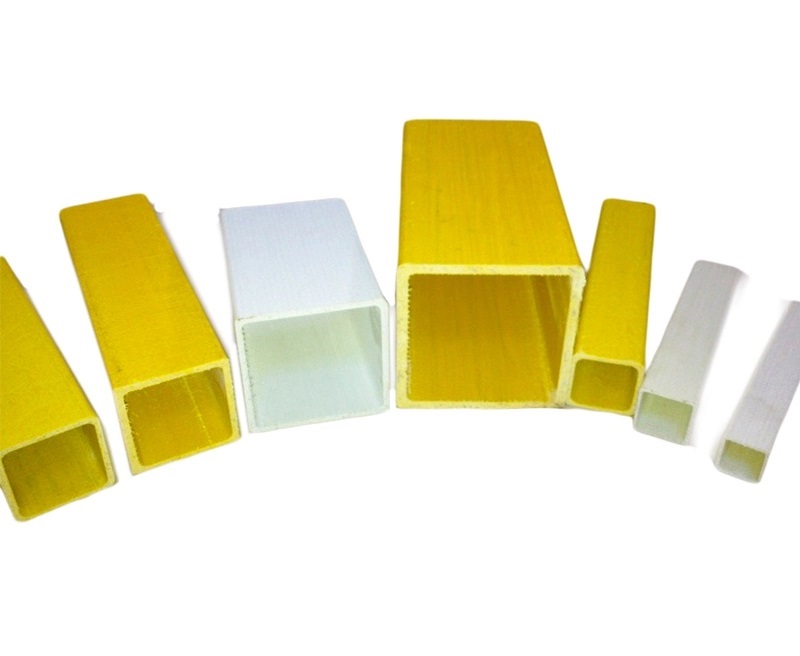

Any constant cross-section profiles can be pultruded. Pultrusion allows the designer to customize the selection of the resin system, the type and form of fiberglass resinforcements, and the placement of the reinforcements within the composite profile. Typical pultruded profiles include FRP Angle, Square Tube, I Beam, Channel, Round Rod, Round Tube, T Beam, etc.

Different kinds:

FRP profiles have a lot of kinds, glass fiber reinforced plastic pipe, glass fiber reinforced plastic square tube, glass fiber reinforced plastic rectangular pipe, glass fiber reinforced plastic round bar, FRP flange beam.

The FRP profiles of the basic components for resin and glass fiber (including cloth, felt, etc.), it is a fiber (including glass fiber, carbon fiber, organic fiber and other metal, non-metallic fiber) as the reinforcing material to resin (mainly epoxy resin. Polyester resin, phenolic resin) for glue linker, auxiliary other auxiliary materials (main materials: release agent, curing agent, catalyst, sealing die agent, UV light stabilizer, clean die water, gel coat, etc.) composite and become. It has high temperature resistance, corrosion resistance, high strength, small specific gravity, low moisture absorption, extension small and insulation good and a series of excellent characteristics.

Properties of FRP pultruded profiles

A. High strength (high tensile strength)

FRP is stronger than structural steel on a pound-for pound basis. It has been used to buildings, walkway, sub-floors and platforms.

B. Light weight (easy to shipment and easy installation)

FRP is 20-25% the weight of steel and 70% the weight of aluminum. FRP are easily transported, handled and lifted into place. Total structures can often be preassembled and shipped to the job site ready to installation.

C. Anti-corrosion

FRP will not rot and are impervious to a broad range of corrosive elements. This feature makes FRP a natural selection for indoor or outdoor structures in pulp and paper mills, chemical plants, water and sewage treatment plants, structural near salt water and other corrosive environments. It is weathering resistant, aging resistant, water proof, rodent proof and corrosion preventive.

D. Electro-magnetic transparency

FRP are transparent to radio waves, microwaves and other electromagnetic. It is widely used to make antennas.

E. Non-conductive

FRP has low thermal/ electrical conductivity.

F. Dimensional stability

The coefficient of thermal expansion of FRP is slightly less than steel and significantly less than aluminum.

G. Aesthetics

FRP are pigmented throughout the thickness of the part and can be made to virtually any desired custom color. Special surfacing veils are also available to create special surface appearances such as wood grain, marble, granite, etc.

Craft and Raw Materials

FRP pultruded square tubes are manufactured with the pultrusion process after choosing the correct raw materials major including the resin, fibers and additives according to the profiles requirement including mechanical strength, electrical insulation, anti-corrosion etc.

Applications

FRP pultruded square tubes can meet the customer's requirements by using different combination of resin, fibers and others.

FRP pultruded square tubes offer a unique combination of chemical resistance, size stability, high strength, and thermal/electric non-conductivity, etc.

FRP pultruded square tube are widely used for cross arm, cooling tower, chemical processing, oil and gas, electrical and utility, wastewater treatment, transportation, construction etc.

FAQ

Q: What's FRP?

A: Fiber Reinforced Polymer (FRP) is a composite material made of a polymer matrix reinforced with fibers. The fibre are usually glass, carbon, aramid, or basalt. Rarely, other fibre such as paper or wood or asbestos have been used. The polymer is usually an epoxy, vinylester or polyester thermosetting plastic, and phenol formaldehyde resins are still in use. FRP are commonly used in the aerospace, automotive, marine, construction industries and ballistic armor.

Q: Are you Composite (FRP) product manufacturer?

A: Yes, of course. We have our own factory and we can provide excellent goods at competitive price.

Q: How can you guarantee your product quality?

A: 100% of our products will be tested before delivery. To control quality, we are using high quality material from high quality supplier.

Q: What's the delivery time will be?

A: It depends. Normally,10~15 working days after receiving your deposit and confirming all the details.

Q: What preferential terms you could give me if I increase the order's quantity?

A:The price depends on quantity ordered, generally more quantity more discount

Applications, industries and uses of round tubes

» Antenna Housings

» Lawn Garden Tool Handles

» Snow Shovel Handles

» Paint roller Handles

» Professional Service Tools

» Arborist Tools/Tree Pruners

» Railing Systems

» Construction

» Elescoping Tools

Applications, industries and uses of square and rectangular tubes

» Insulators

» Railroad Cross Arms/Gates

» Spacers

» Structural Supports

» Framing

» Construction

» Architectural

» Bench Slats

Fiberglass pultruded profiles (structual shapes) are manufactured with the pultrusion process. Glass mat and roving are draw through resin bath pulled a heated die to form the desired shape.

RAMHOIST pultruded profiles are available in a wide variety of shapes, including I beam, equal angle, channel, square tube, round tube, and so on. They are dimensionally stable and easy to install.

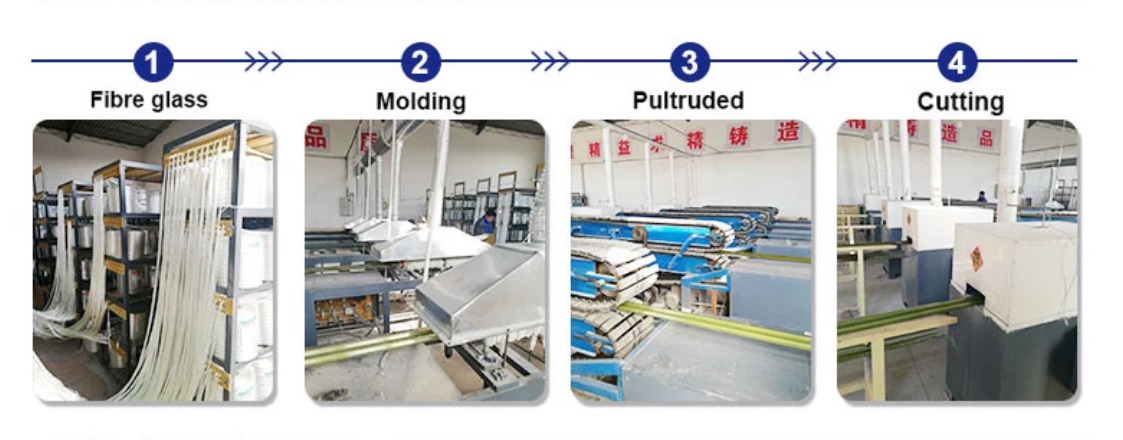

Processing Technique:

FRP Pultrusion production is a continous production process to produce fiberglass reinforced polymer profiles of any length and contstant section.Reinforce-ment fibers may be roving,continous mat,woven robing,carbon or others.The fibers are impregnated with polymer matrix (resin,minerals,pigments,additives) and passed through a pre-forming station that produces the stratification necessary to give the profile the desired properties,After the pre-forming step,the resin-impregnated fibers are pulled through a heated die to polymerize the resin.

Pultrusion Tube has different names such as Pultrusion Pipe, GRP Square Tube, Pultruded Fiberglass Pipe, Pultruded Fiberglass Tube, Pultrusion Fiberglass Tube, FRP Plastic Square Tube, GRP Round Tube, FRP Square Tube, Pultruded Square Tube, Fiberglass Square Tube, Pultrusion Carbon Fiber Pipe, Fiberglass Pultruded Pipe, FRP Pultrusion Tube, Fiberglass Tube, Pultrusion GRP Tube, Pultrusion Square Tube, Fiberglass Pipe, FRP Round Hollow Tube, FRP Round Tube.

Packing

Carton, films or woven belts, if having special request, pls tell us in advance.

Delivery

Process of our tubes

The view of our workshop