Chain slings manufactured from alloy steel or stainless steel are designed for versatile lifting, straight pull, vertical hitches, transporting of goods which can be assembled to meet customers’ own requirement and are the most reputable and reliable product in the rigging and height safety industry. Chain slings inspection must be done periodically since chain slings safety is such an import thing.

• Wide variety of hooks and connects with shortening clutches available

• Resistant to corrosion, rust, abrasion and cutting, very durable and reliable

• New, fully tested and certified which made from high grade chain and fittings

• High and powerful quality with professional technology making perfect

• Convenient and be formed with lifting ring and other accessories

• Adopt high grade alloy steel, anti-high temperature with elongation

• Flexible, long-lasting, collapsible for easy storage and carry

• Safe and securely adhere to the contours of the load

• Welded version offers security of tamper-proof assemblies

• Fully compliant with high standard and assembled by trained and qualified personnel

• Length is completely adjustable, great for use with various picks

• For use at temperatures exceeding 100°C or below minus 40°C

• Comes furnished with a permanent metal load tag that indicates chain size, length and WWL

• Provide excellent lifting in extreme conditions and applied to many fields

• Decent and low price and on-time delivery with great package

• Can be repaired, proof tested and recertified

• Great for lifts with two pick points for greater load stability

• Nonstandard chains or other size can be customized to meet customers’ requirements

• Stretch up to 15 to 20% prior to failure and show little or no stretching at rated capacity

Capacity 1.12ton-11ton

Surface Powder coated, polished, painted, Zinc, HDG, blacken finished

Process Forged, quenched and tempered

Samples Supplied

Material Alloy steel or stainless steel

Color Red, yellow, black and others

Certificate TUV, CE

OEM Acceptable

Factory inspection Available

Structure Welded and combined chain

Standard or nonstandard Standard

Delivery By sea and by air

Size Standard size and others are required

Application Load lifting, lashing, pulling and dragging

Safety factor 4:1

HS code 73269090

Packing Iron drum, pallet or others

| PDF DOWNLOAD |

Chain slings manufactured from alloy steel or stainless steel are designed for versatile lifting, straight pull, vertical hitches, transporting of goods which can be assembled to meet customers’ own requirement and are the most reputable and reliable product in the rigging and height safety industry. The main advantage with chain slings is that they can easily be repaired if any damaged component or link is found during inspection. They are the most resilient type of slings, which provide the best protection against sharp edges and other wear and tear.

Steel chain slings for lifting have different lengths, combinations of hooks and components depending on the lifting application with suitable load hitch and environment used, which are manufactured by industry-experts using enhanced grade material and latest equipment in agreement with global standards that guarantee every component of the sling meets WLL. and every chain or chain sling is as strong as its weakest link, Our revered clients can acquire these slings from us in a range of customized options. Besides, we provide our slings in different specifications to meet the wide-ranging requests of clients and all chain slings will be strictly checked on numerous parameters of quality before its dispatch. They are not allowed to use unless all the slings are accompanied by a valid declaration of conformity or a certificate of thorough examination. The factors of lifting at an angle, wrapping the chain around a load, or extreme temperature reduce the WLL of the sling substantially must be considered when determining what type of sling is necessary to lift a load.

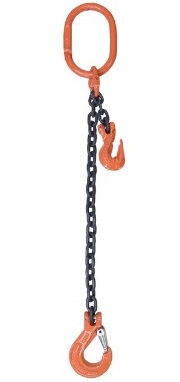

The sling body is comprised of chain with various end fittings, in either single leg or multiple leg configurations and each assembly tested bears a permanently affixed tag displaying the rated capacity. What’s more, components are powder coated and mechanically assembled. Besides, chain slings are made to last and the hook attachments cannot be changed. For overhead lifting, only high-grade alloy steel chains and components may be used. These devices must meet a variety of strict quality standards such as minimum breaking strength, fatigue testing, and heat resistance.

They are widely applied for lashing and lifting hardware, loads, edge loadings in steel factories, steel pipe factories, petrol pipe installing companies, mining, engineering, industrial, construction sites, some situations where other types of slings would fail, particularly through abrasion and extreme hot temperatures. They are also idea lifting equipment for tough environments of high temperatures, hazard or under rugged conditions such as steel mills, chemical mills, foundaries, machine shops and many other extreme conditions that can easily damage other sling types

They are also called quadruple chain slings, alloy steel blackened lifting chain slings, two legs chain slings, chain slings with hooks and master link, single leg chain slings, lifting chains, chain brothers, 4 legs alloy steel chain slings, chain sling bridles, single/double adjustable chain slings, double endless basket slings, rigging chains, two legs lifting crane chain slings and quadruple chain slings.

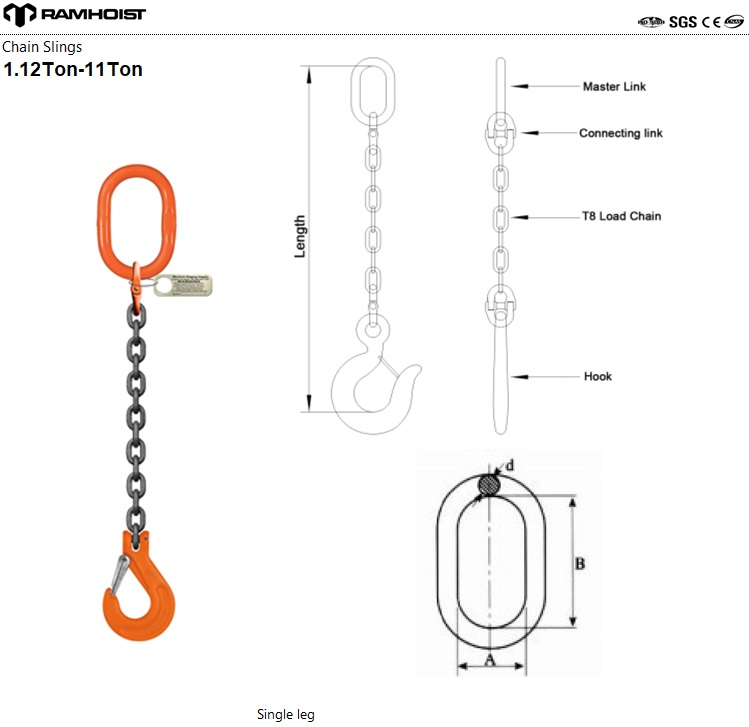

1. Chain

The chains are designed to support a load in a straight line. One thing that to pay attention is that never lower the load onto the chain. And if necessary, operators can use timber battens to rest the load on so that the chain may be easily pulled from under the load. When the chains are in a distorted, reversed and entangled, they are not permitted to use.

2. Hook

There are many types of hooks including grab hooks, clutch hooks, sling hooks, safety hooks, foundary hooks, chain shackles, “C” hooks and others with safety latch. One thing that to pay attention is that operators must make sure that objects must hang on the central of the hook and the edge of the hook shall not be hung in.

3. Master link assembly

The master link assembly is an oblong shaped ring used at the top of wire rope and chain slings, which is very strong and powerful.

4. Connecting link

There are various choices for connecting parts/links such as rings, shackles for different lifting conditions. And the links from the longer sling chain can slide into the grab hooks to adjust the primary lifting chains to the appropriate length for your load.

5. Safe working load tag

Each chain sling has a drop forged ID tag that shows the grade, size, reach, type, working load limit, serial number and other related information. Those ratings are based on ideal conditions, however in practice, working conditions may vary widely. All lifting applications should be assessed by a competent person in order to establish the size and type of sling required.

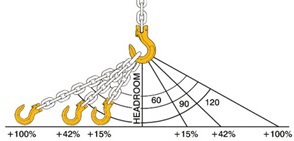

6. Head room

The head room is the distance between the crane hook and the load. The reach of the chain sling must increase as the angle between the legs increases if a specific head room is required.

7. Sling reach|Length

The reach of a chain sling, known as “Bearing to Bearing” is the distance between bearing points of the upper and lower terminal fittings. And the shortening clutches may be fitted to a sling to make the reach adjustable, hence increasing the versatility of the sling.

8. Grade

The WLL (working load limit or rated capacity) of chains and slings is determined by “grade” of the chain and its components. high-grade alloy steel chains and components meeting strict quality standards of minimum breaking strength, fatigue testing and heat resistance shall be used for overhead lifting, the most commonly used chains for overhead lifting are rated at Grade 80, stronger Grade 100 and Grade 120 chains are also available which increase the WLL and lifting capacity.

Types

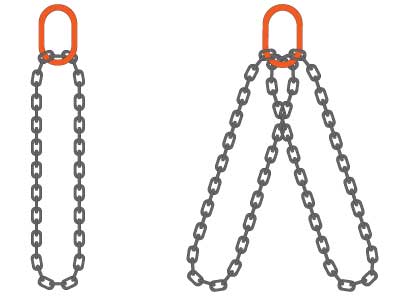

1. Single leg chain slings

This kind of sling chain can be combined with unlimited fittings to suit your application and a length of chain with fittings on each end is used for lifting in a vertical hitch.

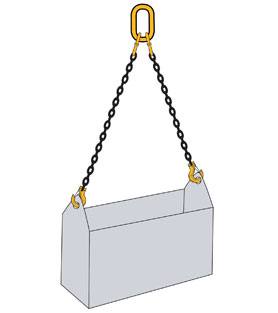

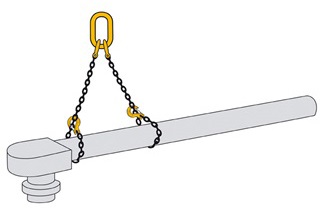

2. Double leg chain slings

The lifting chain is rated for both legs to be used simultaneously at a 60 degree angle, which is joined by an oblong at the top.

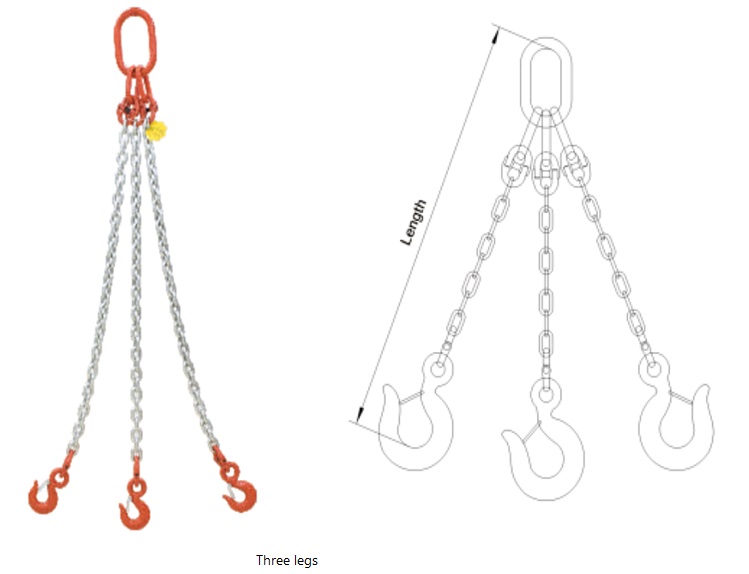

3. Three leg chain slings

Three leg chain slings are rated for lifting when legs are at 60 degree angles from the object, which are joined by a special oblong sub-assembly at the top of the lifting chains.

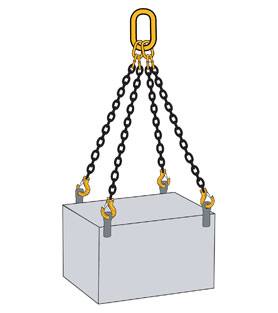

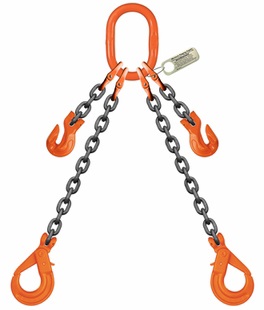

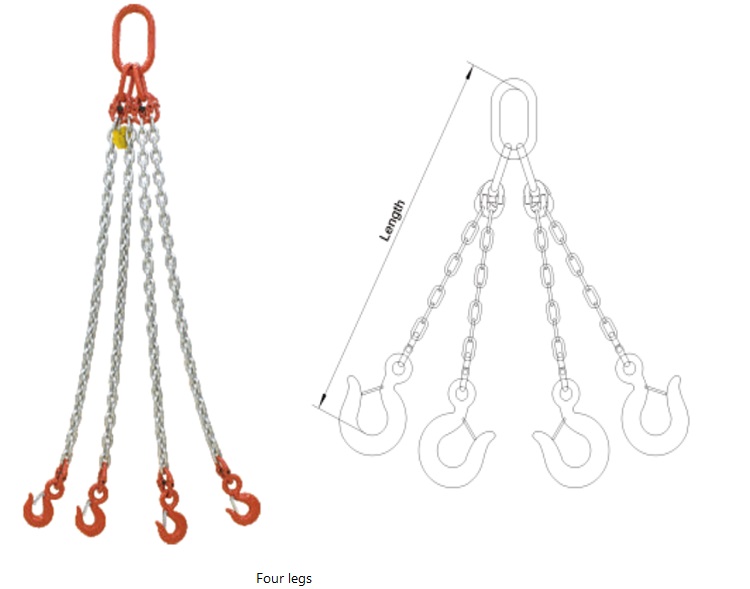

4. Four leg chain slings

Rated to lift using all 4 legs at 60 degree angles, this kind of slings are also joined by a sub-assembly at the top. Four leg chain slings are also called quad leg chain slings or quadruple chain slings.

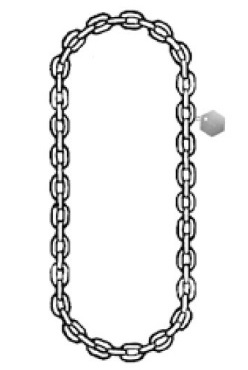

5. Endless chain

There is no oblong included and endless chain is simply an endless loop of chain used for lifting.

6. Single and double endless basket sling

One or two endless loop of chain with an oblong through it allowing the lfting chain to rotate through the oblong freely. Of double endless basket sling, it allows for better load balance across the two legs.

7. Single and double Basket slings

Basket slings include single basket slings (a loop of chain) and double basket slings(two loops of chain) with ends connected by an oblong at the top This kind chain are used to loop under the object to cradle and lift like a “basket”

8. Single and double adjustable chain slings

These kinds of chain slings include single adjustable chain slings and double adjustable chain slings.

with one or two single leg slings and one or two additional shorter leg with one or two grab hooks, This allows you to slide the longer lifting chain's links into the grab(s) hook to shorten the length when needed (adjust the primary lifting chains to the appopriate length for your load.)

Others

1. Cautions

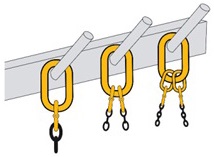

① Sling storage

Operators have to remember that slings must be stowed on a purpose made rack where they will be safe from damage after lifting operations are finished.

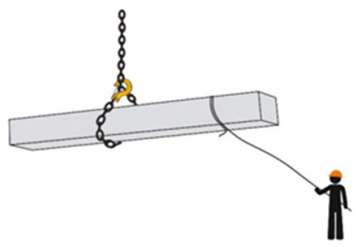

② When in controlling, balancing and landing the load

A tag line has to be attached to control movement of the load during the lift by slingers. The lifting cranes should be vertically above the center of gravity of the load to ensure a level lift. You need to lift just clear of the ground, Re-position the chain sling if the load tilts. And remember always have a prepared landing site ready to receive/land the load and timber battens may be used to rest the load if the load onto the chain so that the chain can be easily pulled from under the load.

③ Tying knots in the chain are forbidden and operators have to make sure chain is free from twists before putting it under tension. You are supposed to use suitable packaging to give the chain protection under the circumstance when the chains have to pass round a sharp corner.

④ Chain slings must be used in the range of its rated loading and the heavy objects shouldn’t be hung in hook for a long period.

⑤ If there are any emergency appears, for instance, the diameter damaged 10% of the original or the chain appears cracks, bending, distorting or surface damage, chain slings should be stopped using immediately.

⑥ While using the chain slings in close proximity of high temperature, extreme care should be taken. Also, it is therefore recommended that the user must always choose to err on the side of safety and make ample provisions for reduced.

⑦ Alloy chain slings couldn’t be used in acidic or lye solutions nor in any other corrosive environment.

⑧ Stainless steel chain slings are ultimate corrosion resistance which particually suitable for offshore use, on board a ship or in the oil and gas industry on board a rig.

2. Hook type options

Sling hook Safety hook Foundary hook chain shackle

“C” shackle Grab hook clutch type

Several hook introduction

① The grab sling hook is a small throat hook that attached to the chain by sliding over the chain between links, which is locked into place by grabbing the chain.

② The slipsling hook is a large throat hook used primarily at the ends of wire rope and chain sling, which is equipped with sring safety latch to avoid disconnect.

③ The foundary hooks are extra large throat hooks used in unique situations that require a larger opening to manage loads

④ Self-locking sling hooks pivot in the middle and lock when lifting pressure is applied, which can’t be opened while unit is lifted with your overhead lifting chains.

3. Temperature of chain

When the temperature is between -40℃-200℃, there is no reduction in load limit while heated

When the temperature is between 200℃-300℃, there will be 10% reduction in load while heated

When the temperature is between 300℃-400℃, there will be 25% reduction in load while heated

But while the temperature is over 400℃, do not use it.

4. Each chain sling is made specifically for users’ job, and the operators have to know the overall reach of the sling, the maxiumload to be lifted, the number of legs, the type of hooks and master links for each leg and other specifications.

5.There are multi leg sling angles and the angle between the legs is critical in the case of multi-leg slings. For the reason that the actual tension on each leg increases as shown in the following chart, all general purpose chain slings are given a rating based upon use at a range of angles up to 45° to the vertical. In the range of angles between45°-60°, a reduced rating is given for use and when the angles are greater than60°to vertical, the chain slings mustn’t be used.

Specifications

Diameter of the Chain | W.L.L. (tons) | Master Link | Weight/M | Additional Weight per 1m Lift | |

A*B*d | |||||

mm | mm | kg | kg | ||

6 | 1.12 | 60*110*13 | 1.7 | 0.8 | |

6.3 | 1.2 | 60*110*13 | 1.8 | 0.9 | |

7.1 | 1.6 | 60*110*13 | 2 | 1.1 | |

8 | 2 | 76*152*16 | 2.5 | 1.4 | |

9 | 2.5 | 76*152*16 | 3.2 | 1.8 | |

10 | 3.15 | 70*140*19 | 3.7 | 2.2 | |

13 | 5.3 | 90*160*22 | 7.9 | 3.8 | |

Specifications

Diameter of the Chain | W.L.L.(tons) | Master Link | Weight/M | Additional Weight per 1m Lift | |

A*B*d | |||||

mm | α≤45° | 45°<α≤60° | mm | kg | kg |

6 | 1.5 | 1.12 | 60*110*13 | 3.1 | 1.6 |

6.3 | 1..6 | 1.2 | 60*110*13 | 3.3 | 1.8 |

7.1 | 2.2 | 1.6 | 76*152*16 | 4 | 2.2 |

8 | 2.8 | 2 | 76*152*16 | 4.3 | 2.8 |

9 | 3.5 | 2.5 | 70*140*19 | 6 | 3.5 |

10 | 4.4 | 3.15 | 70*140*19 | 6.4 | 4.4 |

13 | 7.4 | 5.3 | 89*178*22 | 14.2 | 7.6 |

Specifications

Diameter of the Chain | W.L.L.(tons) | Master Link | Weight/M | Additional Weight per 1m Lift | |

A*B*d | |||||

mm | α≤45° | 45°<α≤60° | mm | kg | kg |

6 | 2.2 | 1.6 | 76*152*16 | 4.9 | 2.4 |

6.3 | 2.5 | 1.8 | 76*152*16 | 5.1 | 2.6 |

7.1 | 3.3 | 2.4 | 70*140*19 | 6.2 | 3.3 |

8 | 4.2 | 3 | 70*140*19 | 6.7 | 4.1 |

9 | 5.2 | 3.75 | 90*160*22 | 9.8 | 5.3 |

10 | 6.6 | 4.7 | 89*178*22 | 10.3 | 6.6 |

13 | 11 | 4.9 | 89*178*25 | 22.3 | 11.4 |

Diameter of the Chain | W.L.L.(tons) | Master Link | Weight/M | Additional Weight per 1m Lift | |

A*B*d | |||||

mm | α≤45° | 45°<α≤60° | mm | kg | kg |

6 | 2.2 | 1.6 | 70*140*20 | 6.8 | 3.2 |

6.3 | 2.5 | 1.8 | 70*140*20 | 7 | 3.5 |

7.1 | 3.3 | 2.4 | 70*140*20 | 7.8 | 4.5 |

8 | 4.1 | 3 | 70*140*20 | 8.4 | 5.5 |

9 | 5.2 | 3.75 | 90*160*22 | 11.4 | 7.1 |

10 | 6.4 | 4.5 | 90*160*22 | 12.2 | 8.8 |

13 | 11 | 7.7 | 90*178*25 | 27.8 | 15.2 |

-

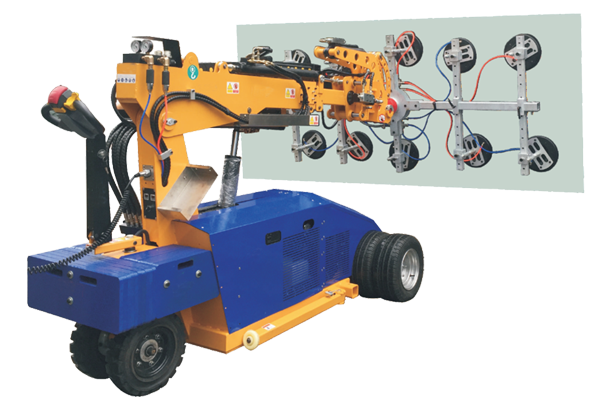

Vacuum Glass Lifters with safety protection systems are designed as one kind of flexible lifting equipments mai…...

-

Vacuum stone lifters with pneumatic motions system, vacuum gripping system and safety protection system are des…...

-

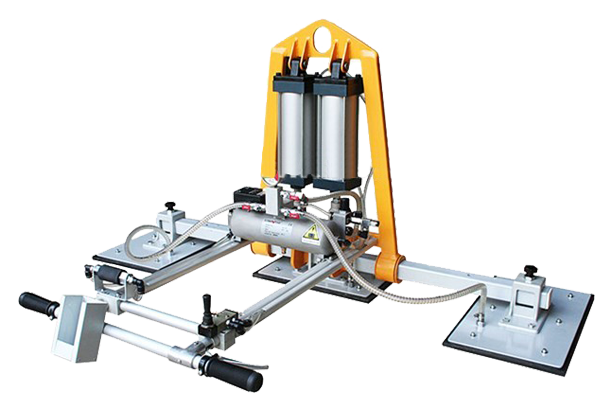

Vacuum tube lifters with air-cut protection, low pressure protection, misoperation protection and safety system…...