Wire rope slings made of strong, high quality carbon steel or stainless steel are designed for lifting and handling balanced and unbalanced loads, which own the great resistance to corrosion, heat, sunlight and most chemicals. There are different types of Wire Rope Slings in below article and wire rope slings must be inspected before each use.

• Safe and easy to lift with high strength and big working load

• Resist against high temperature and abrasion with long life of using

• Safe and reliable with least expensive per capacity of all steel slings

• Good abrasion resistance increases useful life of sling

• Can be used at temperatures up to 400° F with soft eye at each end

• Numerous body constructions for variety of applications

• Countless combinations of sling terminations to fit specific lift requirements

• Available in wire core for strength and fiber core for flexibility

• With reserve strength should the sleeve become damaged in use

• Conform to all European regulations and meet high standard

• Least expensive per capacity of all steel slings

• Color-coded for positive sling capacity identification.

• Non-rotating steel rope for port loaded and unloaded crane equipment

• Available in different sizes and various colors with customized labels and brand

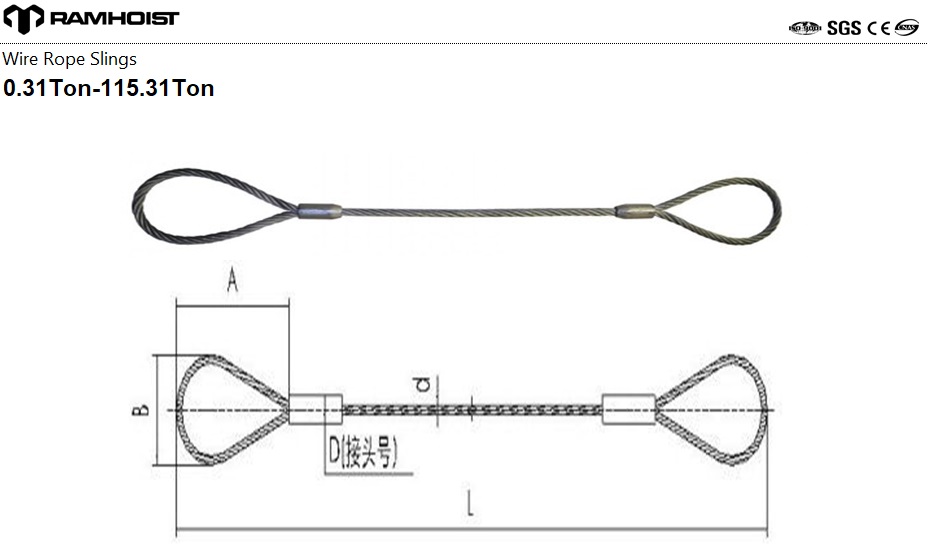

Capacity 0.31ton-115.31ton

Standard AISI, ASTM, BS, DIN, GB, JIS

Special use Cold heading steel

Coating Bright and galvanized

Shape Round

Material Carbon steel, stainless steel

Sling color Sliver

Lifting eye type Folded eye

Certification ISO 9001:2008

Safety factor 5:1

Sample Free

Parts Wire rope, sleeve ferrules, thimbles and others

Process Press

Surface treatment Electro galvanized or others

Uses Lifting and handling loads

HS code 73121000

Package Wooden case, cartoon case and pallet

Wire rope slings made of strong, high quality carbon steel or stainless steel are designed for lifting and handling balanced and unbalanced loads, which own the great resistance to corrosion, heat, sunlight and most chemicals. One of the advantages of them is that they make a cable laid sling more flexible and resistant to kinking than traditional wire rope configuration, which offer a strong, dependable and economical option for most applications. All of wire rope lifting slings are manufactured with an attached metal tag displaying capacity, care, and instruction for easy and convenient use for customers.

Wire rope slings for lifting adopt coated plastic as the main material and galvanized finish of wire rope to help lifting slings prevent from abrasion and erosion. And with the aluminum alloy, both in the shoulder, they can avoid sharp wire edges. Especially the single leg type wire rope design, they can be used in a range of hitches and angles. What’s more, wire rope slings are fully equipped sling unit with the latest state of art technology comprising proof load testing machine up to high capacity, hydraulic slicing machine capable of slicing up to various diameter wire rope slings.

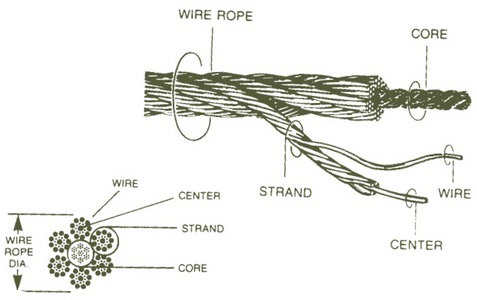

Steel Wire rope slings are several strands of metal wire twisted into a helix that can form into a composite "rope", known as "laid rope" in a pattern. Besides, wire rope slings with large diameter consist of multiple strands of such laid rope. Manufactured by using the premium quality steel wire rope, using the advanced technology and procured from our reliable vendor, They are highly acclaimed by our clients, mainly due to their durability, safety, longevity, corrosion resistance, availability at reasonable prices and so on. They are only as good as their end termination.

In order to produce a safe and reliable wire rope slings, it involves more than simply just having a press a length of wore rope and fittings. The popularity of wire rope slings is gradually enhanced by the numerous sling configurations available which includes single and multi-part slings (such as round braids, flat braids and cable laid slings), grommets, single leg slings, multiple leg bridles, and a wide variety of fittings and attachments to support a broad range of applications. There are various types and different sizes wire rope slings available, and they are custom built to meet your specific needs for any application.

They are widely applied for lifting boilers, cases and handling unbalanced loads in machinery, metallurgy, construction, upper plates of bridges, shipping, oil field, fishing, floor and roof reinforcement for sports stadiums colliery and ports etc. They are also used as cable for special bridges and for the maintenance of bridges, and used widely for building wall boards, sea oil platforms, stairs and many tube porch products and other industrial fields.

They are also called 4 legs wire rope slings, stainless steel wire rope slings, galvanized/galvanized rope cargo lifting slings or lifting tools, endless wire rope slings, four leg bridle wire rope slings, PA coated steel wire rope sling, PVC coated steel wire rope sling, copper wire rope slings, solid pressed thimble wire rope slings, eye-eye wire rope slings, steel wire rope lifting slings, extra soft grommet slings, flat rope slings, stay cables with swaging sockets and slings with clamps for lifting plates.

Wire rope slings adopt precast concrete construction and the main parts include wire rope, inner core, strand, center, steel wire, steel stocks and others.

Bare

With plastic thimble

2.Surface treatment

Wire rope slings adopt electro galvanizing or others.

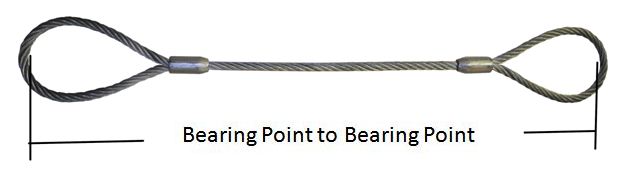

3,Bearing point

Length of wire rope slings are from bearing point to bearing point.

4.Sizes

We can customize various kinds of rigging according to customers’ requirement. Usually, the minimum circumference S of the sling is 50 times the wire rope diameter and the bending radius must be not less than 4 times of the wire rope diameter. The zone between the clamps can’t be bent under lifting force and the length is intended to be the dimension measured between the bearing points of the slings and the measured length of a ferrule-secured sling shall not differ from the nominal length by more than two rope diameters or 1% of the nominal length.

5. Eye|Socket

There are various sockets available such as open socket, closed socket and others. Also, the eye type include Flemish eye, pressed soft eye, spliced eye, thimble eye, standard eye, hard eye at both end.

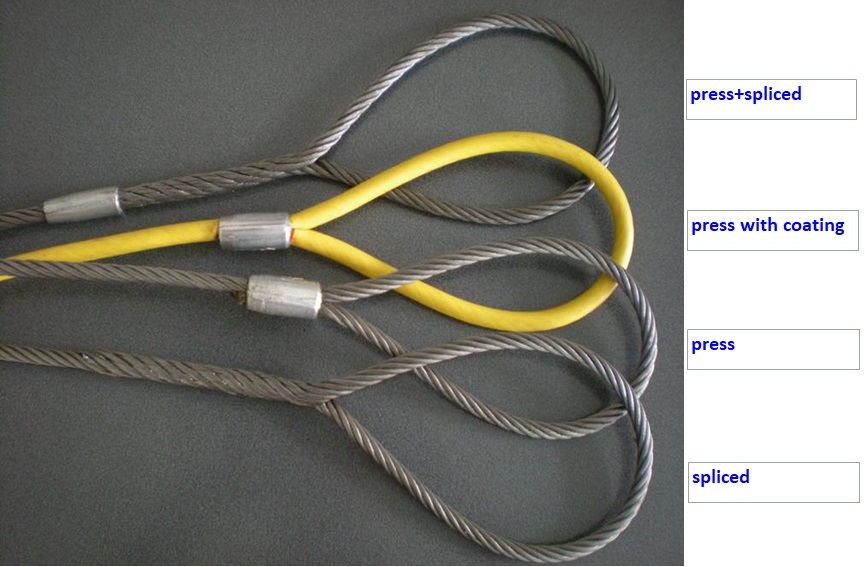

Four types of eyes

6. Hitches

There are three basic hitches including vertical hitches, choker hitches and basket hitches.

①Vertical hitches are made directly from the crane hook to the load. Full rated capacity of the slings may be used but never exceeded. A tagline should be attached to prevent rotation which can damage the sling. A sling with a hand-tucked splice can’t lay and fail if the sling is allowed to rotate.

②Choker hitches reduce lifting capability of a sling, since this method of rigging affects the ability of the wire rope components to adjust during the lift, places angular loading on the body of the sling, and creates a small diameter bend in the body at the choke point.

③Basket hitches distribute a load equally between the two legs of a sling. Rated capacities are influenced by sling angles.

|

|

|

Vertical Breaking Strength | Choker Breaking Strength | Basket Breaking Strength |

7. Fixing

They are equipped to fix the slings.

Wire Rope Socket Wire Rope Socket Swaged Mechanical Splice

(Poured Spelter or Resin) (Loop or Thimble)

Splice Hand Tucked Wedge Socket Clips

(Loop or Thimble)

8. Elements

9. PVC/PE/PU coated Galvanized Pressed Steel Wire Rope Slings

Others

1. Process

①At first, the wire rods experience surface treatment

②Then, wire rope slings will experience drawing, stranding, and coating, which includes heat treatment and cooling treatment.

③At last, they will be packaged and delivered to the customers.

④They will received heat treatment, polishing short blasting, painting, electro-plating chemical plating,

2. Different socket types

Soft eye hand spliced Thimble eye hand spliced

Soft eye machine swaged Thimble eye machine swaged

Steel ferrule machine swaged closed swag socket

Opened socket Closed socket

3. Lay

There are various lays including right hand regular lay, left hand regular lay, right hand Lang lay, left hand Lang lay, right alternative regular lay and left alternative regular lay.

4. Packaging Details

Wire rope slings are always packaged in plywood reel/plastic reel/wooden reel/coil in container, and then they will be palletized or put into a crate or a box.

5. Different types of wire rope slings

There are various types of wire rope slings including slings with soft eye, hoist slings, slings with soft eye and two legs, steel ferrule secured slings, slings with Flemish eyes, ferrule secured endless slings, slings with steel-ferrule secured end stops, slings with swaged steel tie rod, slings with single hook, slings for crane, slings with sockets, slings with master link and two legs, slings with cuneiform connector, flat wire rope mesh slings, slings with master link and four legs, endless wire rope slings, container lifting slings for sea oil platform, large diameter cable laid slings, slings for lifting reinforcing steel bars, cable laid grommet slings, cable stocking, slings with spliced eye termination and others, and the main products are as following.

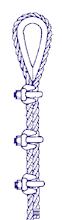

A. Single leg wire rope slings

B. 2/Double leg bridle wire rope slings

2-Leg bridle slings constructed of two wire rope assemblies that are attached to an oblong ring are designed for general lifting when the attachment can be made directly to the load. The lifting ends of the wire rope legs can be fitted with a variety of hooks, eyes, or rings to allow attachment to nearly any object. The advantage of wire rope slings is that they are resistant to corrosion, heat, sunlight and most chemicals and they are custom built to meet your specific needs for any application.

C. 3 leg bridle wire rope slings

3-Leg bridle wire rope slings constructed of three wire rope assemblies that are attached to an oblong ring are designed to handle unbalanced loads. The lifting ends of the wire rope legs can be fitted with a variety of hooks, eyes, or rings to allow attachment to nearly any object. We carry a range of wire rope slings in our hire fleet with soft eye configurations at each end, available in various capacities and effective working lengths.

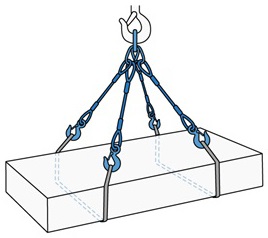

D. 4 leg bridle wire rope slings

4-Leg bridle wire rope lifting slings constructed of four wire rope assemblies that are attached to an oblong ring are designed for balanced or unbalanced loads and for heavy lifts when the weight can easily be distributed over four points. The lifting ends of the wire rope legs can be fitted with a variety of hooks, eyes, or rings to allow attachment to nearly any object.

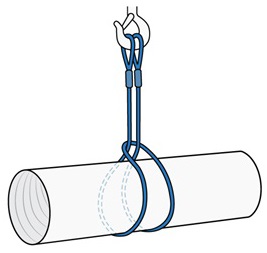

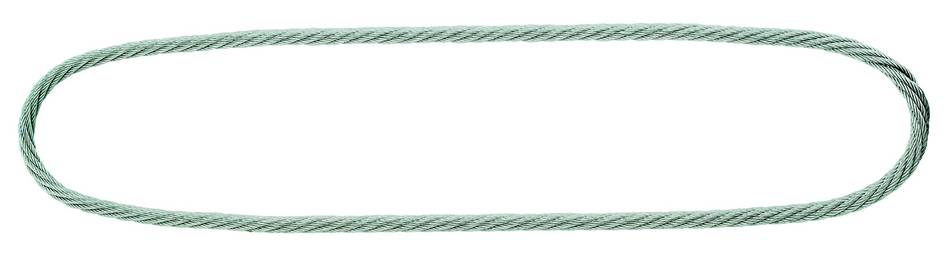

E.Endless wire rope slings | Steel wire rope endless slings

The endless wire rope slings are orbicular, economical and adaptable slings with no fixed wear points, using special technology and the most advanced equipment and known for its softness, high tension and increased suspension points. They are suitable to lift and move tubes, pipes and long metal parts which suited in small and limited spaces and for high/large lifting loads, they are also adaptable for special bulk hoisting requirements of different conditions, such as transformers, shipbuilding and special machinery (where the warning mark locates cannot be used as lifting point)

Slings can be realized with galvanized or ungalvanized wire rope, special rope protected by strong PVC sleeve to resist against sharp edges without damaging the goods surface is also available as per your request.

F. More wire rope slings

With round solid thimble

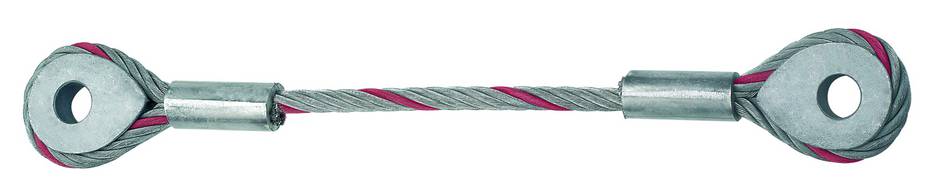

With swaging sockets (jaw-jaw)

With swaging sockets (jaw-eye)

With swaging sockets (eye-eye)

With swaging sockets (flt-flt stud-stud)

Spelter sockets (open-open)

Spelter sockets (open-closed)

Spelter sockets (closed-closed)

Pear type

6. Angle type

![]()

7. According to the strength, wire rope slings can be divided into vertical breaking strength, chocker breaking strength, basket breaking strength, and except for standard eye size, thimble eye size, there are others of different eye hook capacity.

8. Cautions

If you come into the following conditions, you have to take the sling replacement for consideration

①For strand laid and single part slings, ten randomly distributed broken wires in one rope lay, or five broken wires in one strand in one rope lay.

②For cable laid and braided slings of less than 8 parts, twenty randomly distributed broken wires in one lay or braid, or on broken strand per sling.

③Severe localized abrasion or scraping, kinking, crushing, bird caging or any other damage resulting in distortion of the wire rope structure.

④Evidence of heat damage or if a wire rope sling having a fiber core is exposed to temperatures in excess of 200° F or if a wire rope sling having a steel core is used at temperatures above 400° F or below minus 60° F.

⑤Corrosion of the rope or end attachments or not laying and opening up of a tucked splice. Also, when end attachments that are cracked, deformed, or worn.

⑥Deformation—any visibly apparent bend or twist from the plane of the unbent hook. Throat opening—any distortion will cause an increase in throat opening of 5% not to exceed capacity.

⑦Avoid twists, kinks and knots before lifting, store wire rope slings where they will not be subjected to dirt, moisture, extreme heat, corrosion or mechanical damage.

⑧Protect the sling body against sharp edges and corners of loads, protrusions or abrasive surfaces. Sharp bends can distort wire rope and reduce its strength.

⑨Never "shock load" wire rope slings, the actual force caused by a sudden application of load can easily exceed rated capacities and damage slings and abruptly releasing a load can also damage the slings.

Specifications

Nominal Diameter | 1570 N/mm2 | 1670 N/mm2 | 1770 N/mm2 | |||

MBL (t) | SWL (t) | MBL (t) | SWL (t) | MBL (t) | SWL (t) | |

6 | / | / | / | / | 2 | 0.33 |

9 | 3.63 | 0.31 | 3.87 | 0.64 | 4.1 | 0.68 |

10 | 4.48 | 0.75 | 4.77 | 0.8 | 5.06 | 0.84 |

12 | 6.46 | 1.08 | 6.87 | 1.15 | 7.28 | 1.12 |

14 | 8.79 | 1.47 | 9.35 | 1.56 | 9.91 | 1.65 |

16 | 11.48 | 1.91 | 12.21 | 2.04 | 12.95 | 2.16 |

18 | 14.53 | 2.42 | 15.46 | 2.58 | 16.39 | 2.73 |

20 | 17.94 | 2.99 | 19.08 | 3.18 | 20.22 | 3.27 |

22 | 21.71 | 3.62 | 23.09 | 3.85 | 24.48 | 4.08 |

24 | 25.84 | 4.31 | 27.48 | 4.58 | 29.13 | 4.86 |

26 | 30.33 | 5.05 | 32.26 | 5.38 | 34.18 | 5.7 |

28 | 35.16 | 5.86 | 37.41 | 6.23 | 39.65 | 6.61 |

30 | 40.37 | 6.73 | 42.94 | 7.16 | 45.51 | 7.59 |

32 | 45.4 | 7.57 | 48.37 | 8.06 | 51.43 | 8.57 |

36 | 57.34 | 9.56 | 61.22 | 10.2 | 65.1 | 10.85 |

40 | 70.72 | 11.78 | 75.62 | 12.6 | 80.41 | 13.4 |

44 | 85.62 | 14.27 | 91.43 | 15.24 | 97.25 | 16.21 |

48 | 101.1 | 16.85 | 108.16 | 18.03 | 115.31 | 19.22 |

Dimensions (mm)

Nominal Diameter | d | D | A | B | ||

6 | 6 | 6 | 160 | 80 | ||

9 | 9 | 9 | 200 | 100 | ||

10 | 10 | 10 | 240 | 120 | ||

12 | 12 | 12 | 240 | 120 | ||

14 | 14 | 14 | 240 | 120 | ||

16 | 16 | 16 | 280 | 140 | ||

18 | 18 | 18 | 320 | 160 | ||

20 | 20 | 20 | 360 | 180 | ||

22 | 22 | 22 | 400 | 200 | ||

24 | 24 | 24 | 440 | 220 | ||

26 | 26 | 26 | 480 | 240 | ||

28 | 28 | 28 | 520 | 260 | ||

30 | 30 | 30 | 560 | 280 | ||

32 | 32 | 32 | 600 | 300 | ||

36 | 36 | 36 | 640 | 320 | ||

40 | 40 | 40 | 680 | 340 | ||

44 | 44 | 44 | 720 | 360 | ||

48 | 48 | 48 | 760 | 380 | ||

1570 N/mm2, 1670 N/mm2, 1770 N/mm2 is minimum breaking load for nominal tensile strength of rope

MBL=Maximal Beyond Load

SWL=Safe Working Load

-

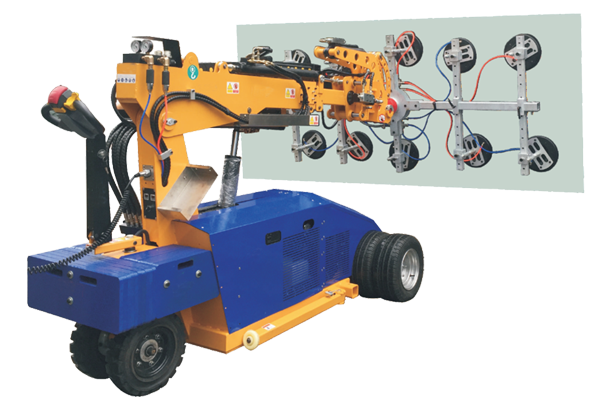

Vacuum Glass Lifters with safety protection systems are designed as one kind of flexible lifting equipments mai…...

-

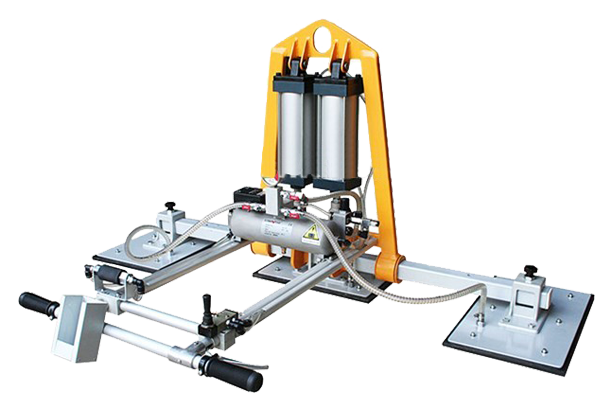

Vacuum stone lifters with pneumatic motions system, vacuum gripping system and safety protection system are des…...

-

Vacuum tube lifters with air-cut protection, low pressure protection, misoperation protection and safety system…...