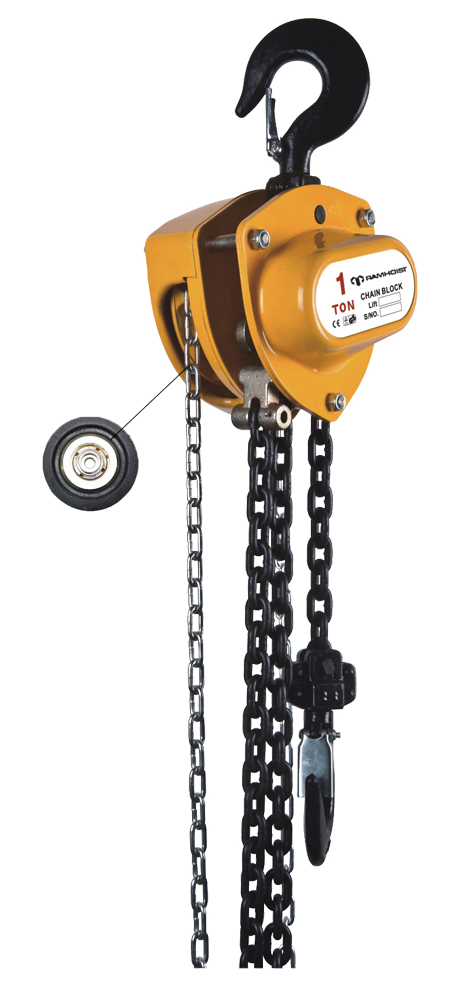

Chain Blocks are the kind of simple to use and easy to carry manual lifting machinery, which controlled only by pulling handlebar chain. They are explosion proof chain blocks or Non sparking chain blocks, As the small material handling equipment, spark proof HSBQ chain blocks are used to lift something in hazardous industries.

• Reasonable and reliable structure with high quality, as well as outstanding appearance

• Light weight and small volume provide comfortable and convenient operations

• Unique and exquisite design from professional workers makes our products more durable

• Low cost in maintenance and repair, and is very simple for workers to operate them

• Reasonable price and fast delivery help our products more competitive than others

• Polished or electrostatic spraying load chains provide a longer service life to our blocks

• The open frame design makes the process of self-cleaning become more easy and simple

• High-quality stainless upper and lower hooks make the lifting loads become more safe

• Adopted to H62 copper alloy material as the surface to improve the durable operations

• 100% test before assembling and loading guarantees the good quality of our products

• Market agent support and after-sale service are the good qualifications of our company

• Equipped with overload protection to protect our blocks from the situation of overloading

• All components are made of good quality copper to ensure the high safety and security

• No mechanical spark will be generated in the operations to prevent some fire accidents

• Our products absolutely conforms to European CE and other international safety standard

• Supplied to our customers with the most important commitment, one year warranty

Capacity 0.5T-50T

Lifting Height 2.5m-3m

Type HBSQ Chain Hoist

Condition New

Power Source Manual

Certification CE, ISO

Material Aluminum Bronze & Beryllium Bronze

Lifting speed Manual

Hooks Forged Alloy Steel

Use Lifting Up/Down

Shape Rounded

Drive Mode Gear

Sling Type Chain

Usage Construction Hoist

Operation Hand operated

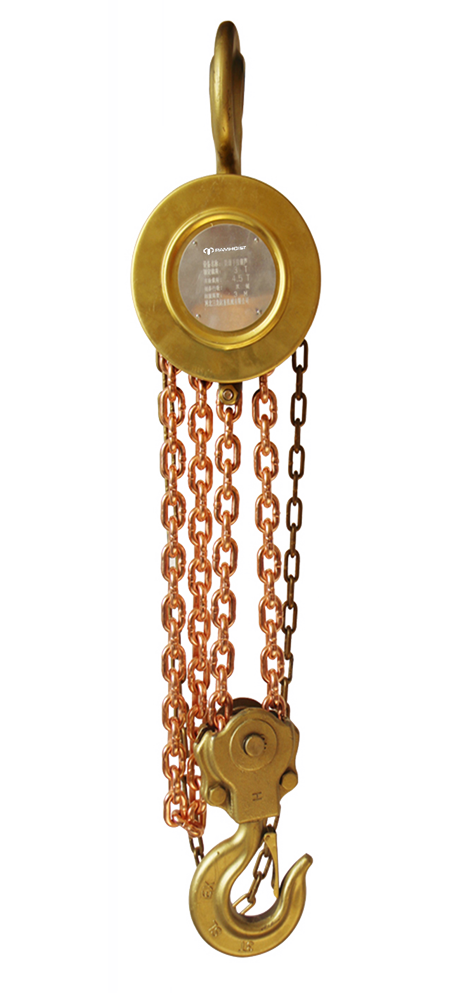

Color Golden

HBSQ Chain Blocks are the kind of simple to use and easy to carry manual lifting machinery, which controlled only by pulling handlebar chain. They are explosion proof chain blocks, As the small material handling equipment, spark proof HSBQ chain blocks are used to lift something in industries, and also can avoid the flammability explosion which happens when there are some frictions and crash between the hoist and the goods. Due to the special material adopted, They can be widely used in the hazardous environment such as petroleum, chemical industry and gas extraction.

The working principle of our explosion proof chain blocks is very easy to understand. It starts to turn through tracer chain and sprocket; the friction disc ratchet wheel and brake seat (pressed into a whole) rotate together; the five-tooth long shaft turns the piece gear, four-tooth short shaft and spline-hole gear. As a result, the sprocket installed on the spline gear drives the chain and lifts the weight stably.

Our explosion proof chain blocks have the characteristics of small tension, light pulling, small weight, bright appearance and long service life. The calabash is made of special material, which can avoid the friction and impact of mechanical sparks when working in the dangerous environment of potential fire and explosion. And the special materials are aluminum bronze and beryllium bronze, which are relatively expensive production materials. All main components of HBSQ explosion proof chain blocks like gears, sprockets and hand wheel covers are made of the advanced-technology material of copper alloy through die forging of large friction press machine. The shell of the hand-pulled calabash is made of H62 copper alloy. The rotating gears of the explosion proof chain blocks are subjected to high temperature heat treatment so that the gears have high wear resistance. Stainless steel hand chains adopt 800MPa high-strength lifting chain, which make our chain blocks more durable. What’s more, those accessories in casting is installed, debugged and tested in according with the general hoisting equipment national standards strictly, and its performance of explosion-proof is in line with GB/10686-1989 standards completely, and also each data coincides with Q/QJY01-2008 stands totally.

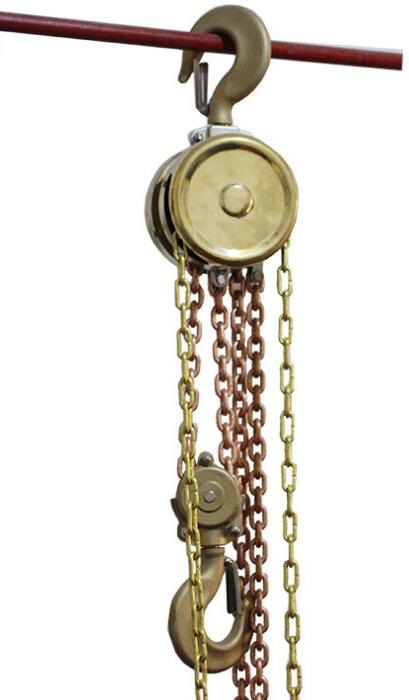

Due to the high-technology, all our HBSQ explosion proof chain blocks have the good meshing between the tooth groove of the ratchet wheel and the pawl of the ratchet wheel. However, when installing the brake device, please check again just in case. And the spring should be flexible and reliable in controlling the ratchet claw. Therefore, after installing the sprocket wheel, please rotate the sprocket wheel clockwise to press the ratchet wheel and friction plate on the brake seat. What’s more, the operator should stand in the same plane with the hand sprocket when pulling the hand chain, so that the hand sprocket rotation along the clockwise direction, which can highly make the process of lifting loads become more easy and convenient. And if the operators want to put the loads down slowly, just pull back on the chain is OK.

HSBQ explosion proof chain blocks can be widely used in petroleum, petrochemical, gas station, oil depot and gas extraction, chemical industry, military industry, electric power, mining, electronics, railways, and other potential and explosion dangerous environment. What’s more, product friction in operation will not produce mechanical spark, which effectively prevents the fire accident and ensures that factory’s property and personal safety, the explosion proof chain blocks are also the special tool, which are essential for machinery manufacturing and maintenance. And in the places without power and outdoors, it is more advantaged and favorable.

Besides, our HBSQ explosion proof chain blocks also can be used alone with electric hoist, chain or electric car together. Except hanging on the roof of the building or using on the crane beam, it also can cooperate with monorail car and walk around ascension weight functions as well as help to install electric hoist.

HBSQ explosion proof chain blocks are also called Explosion-proof chain blocks, Non spark chain blocks, Explosion-proof chain hoists, Non spark chain hoists, Non sparking chain hoists, Non sparking manual chain hoists, spark proof chain pulley blocks, spark proof chain hoists, spark resistant chain hoists, spark resistant chain blocks, spark resistant hand chain hoists, Anti-explosion chain blocks, Anti-explosion chain hoists, Copper chain blocks, Copper alloy safety chain blocks and Explosion proof copper anti sparking chain blocks.

1.Shell

All copper shell is thickened and strengthened, which can completely protect the internal parts and provide safer explosion protection for the operators. And the outer shell adopts H62 copper alloy material to be applicable in flammable and explosive occasions, such as chemical industry, sea and other operations.

2.Hooks

The forging hook has strong impact and pressure resistance, and is not easy to break and deform. The advantages of high strength, strong toughness, and non-deformation provide a long service life to our chain blocks.

3.Latch

The latch has the function of preventing the weight from falling off the hook. Heavy duty of our latch makes it more competitive than other brands in market. And the stuck design provides more safety and security for the operations of lifting loads.

4.Guide Wheel

The guide wheel perfectly fits the trend of chain, and highly prevents the stuck form chain. Small resistance and smooth introduction can fully ensure the good performance of guide wheel.

5.Chain

Forging chain is treated with special technology, strong and wear-resistant, as well as not deformed easily.

High bearing capacity and high quality strength of the chain make the chain not easy to break and durable.

6.Gears

Gears adopt special material, and have the purpose of making sure the smooth and steady operations of our products.

7.End Anchor

End anchor is located on the end of hoist plate, which has the purpose of withstanding more force and attack. High-quality end anchor can prevent some dangerous situations from our explosion proof chain blocks.

8.Structure

The structure adopts the technology of whole integral sealing, which is compact and light. High-quality structure also makes the maintenance and repair of chain blocks become more convenient and simple.

9.Lifting Sprocket

High strength and wear resistance, good corrosion resistance and oxidation resistance at high temperature makes the chain run more smoothly.

10.Trolley

Trolley is an optional component of our HSBQ chain blocks. Durable wheel and reasonable structure make the operations of lifting goods become more smooth and steady.

11.Mark

The mark sticks on the shell, which is intended to introduce the basic information of our chain blocks. And it also can warn to operators when lifting goods.

12.Bolts

Bolts play a necessary part in our products, which is used to connect main parts of HSBQ chain blocks. High quality H62 copper alloy material totally makes sure the high-effective operations in the process of lifting goods. .

Others

①Cautions

Overload and power operation other than manpower, as well as improper operation such as heavy object hanging on the tip are all strictly prohibited.

Please make sure the parts are in good condition before use. The transmission part and lifting chain are well lubricated and idling is normal. Please check whether the upper and lower hooks are fastened before lifting.

The hoisting chain of HBSQ explosion proof chain blocks should be hung vertically. And there should be no wrong twisted chain link.

When lifting heavy objects, it is strictly forbidden to do any work or walk under the heavy objects to avoid personal accidents.

The gourd should be cleaned and coated with anti-rust grease after using, and stored in a dry place. Maintenance and overhaul should be carried out by those who are familiar with the gourd mechanism, to prevent those who do not understand the performance principle of the machine from disassembling and assembling at will.

The friction surface of the brake must be kept clean. The brake part should be checked frequently to prevent the brake failure and the phenomenon of falling of the intermediate object.

②Package

1. Individual plastic bag and bubble bag then box.

Specifications

Type | Capacity(t) | Standard Lift (m) | Effort required to lift full load (N) | Load Chain | Test Load (t) | Weight(kg) | Additional Weight per 1m Lift(kg) |

Diameter (mm) ×chain falls | |||||||

HBSQ005 | 0.5 | 2.5 | 225 | 6 × 1 | 0.75 | 9.5 | 1.7 |

HBSQ01 | 1 | 309 | 6 × 1 | 1.5 | 10 | 1.7 | |

HBSQ015 | 1.5 | 343 | 8 × 1 | 2.25 | 16 | 2.3 | |

HBSQ02 | 2 | 314 | 6 × 2 | 3 | 14 | 2.5 | |

HBSQ03 | 3 | 3 | 343 | 8 × 2 | 4.5 | 24 | 3.7 |

HBSQ05 | 5 | 383 | 10 × 2 | 7.5 | 36 | 5.3 | |

HBSQ10 | 10 | 392 | 10 × 4 | 15 | 68 | 9.7 | |

HBSQ20 | 20 | 392 | 10 × 8 | 30 | 155 | 19.4 |

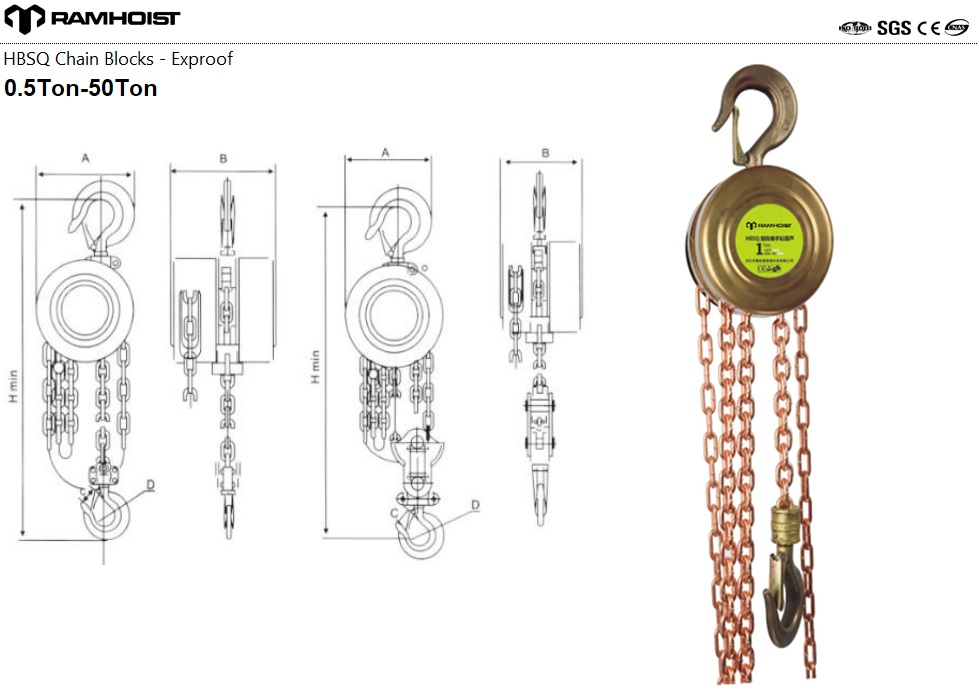

Dimensions (mm)

Type | Capacity (t) | A | B | C | D | Hmin | |

HBSQ005 | 0.5 | 120 | 108 | 24 | 120 | 270 | |

HBSQ01 | 1 | 142 | 122 | 28 | 142 | 444 | |

HBSQ015 | 1.5 | 178 | 139 | 34 | 178 | 470 | |

HBSQ02 | 2 | 142 | 122 | 34 | 142 | 486 | |

HBSQ03 | 3 | 178 | 139 | 38 | 178 | 616 | |

HBSQ05 | 5 | 210 | 162 | 48 | 210 | 630 | |

HBSQ10 | 10 | 358 | 162 | 64 | 210 | 700 | |

HBSQ20 | 20 | 580 | 189 | 82 | 210 | 1000 | |