Single Girder a-Frame Gantry Crane Workshop Gantry Crane with Electric Hoist for Sale

Keyword:Single Girder Gantry Cranes Time:2019-4-13 15:40:11

MH Model Electric Hoist Girder Gantry Crane is used together with CD1/MD1 Model Electric hoist. It is a track travelling small and medium-sized crane. Its proper Lifting weight is 5 to 20 tons. Proper span is 12 to 30 meters and its proper working temperature is -20°C ~40°C.

This Gantry crane is a regular crane widely used at open ground and warehouses to lift, unload or grab materials. It has two controlling methods, namely ground controlling and room controlling.

Main Part:

1. Crane system: 1 main beams, 2 end trucks, 4 leg beams, lifting trolley

2. Power supply system: Flexible cable/ electric cable drum.

3. Crane Travelling system: China national standard crane travel rail P38/P43/P50 rail with clamping plates, pressing plates, rubber cushions, steel cushions, bolts and nuts full set of accessories.

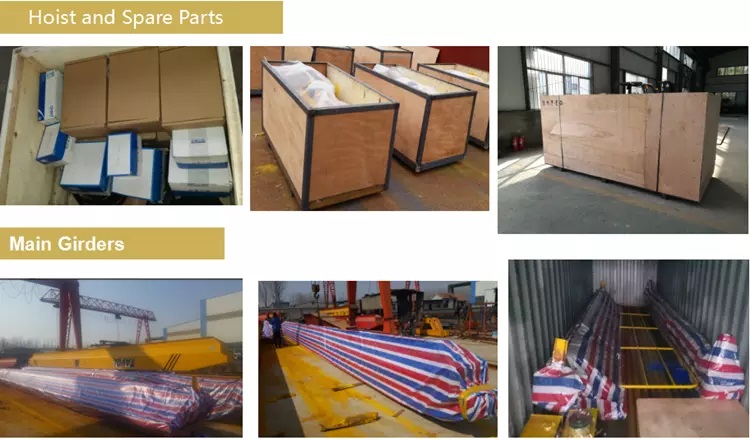

Packing & Delivery

1.Delivery time

Within15~25 working days after the receipt of deposit.

2.Packaging

a) Electric parts are packed by high quality wooden box, to reduce distortion in conveying.

b) Main beams, ground beams are packed by plastic woven cloth. It can reduce abrasion when transport.

c) If the size of the gantry crane are suitable for container ship, usually by container;

d) If the size is too big, usually by bulk ship; Transport ways are based on reducing cost for you and keep the crane performance well.

As this kind of gantry crane is customized, in order to offer you most suitable design and best solution, please confirm following information when you send inquiry.

1. Lifting capacity.

2. Span length.(rail center to rail center)

3. Lifting height.(hook center to ground)

4. Have you installed the rails? Do you need us supply the rails? How long is it?

5. Power supply: Voltage.

6. Working condition: which material to lift? temperature?

7. Would be better if you have drawings of your plant.

8. Nearest port?