Different kinds of Chain Slings made in china

Keyword:Chain Slings Time:2020-3-14 17:48:58

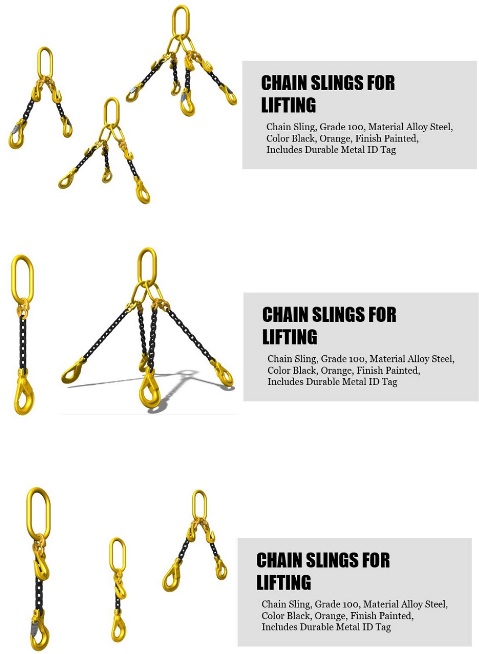

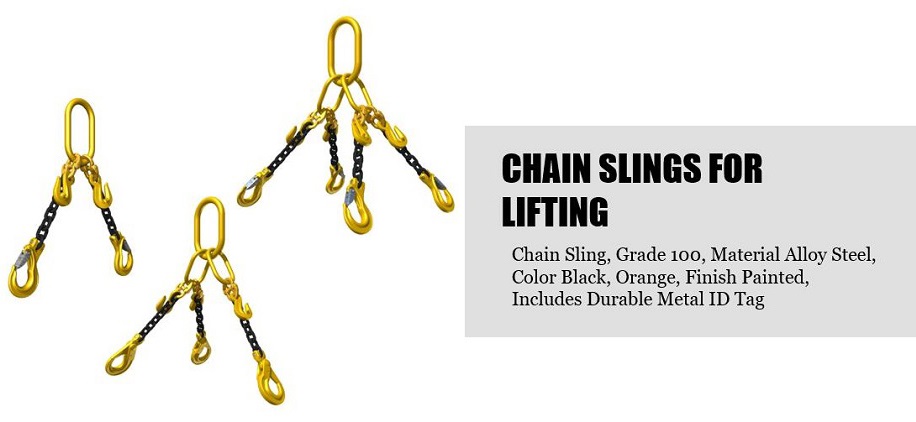

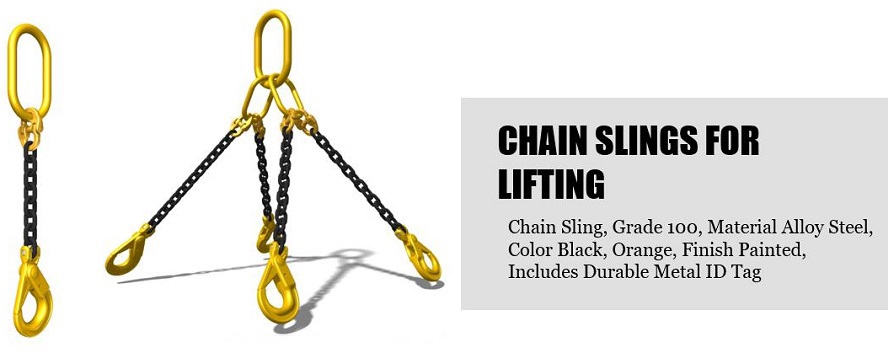

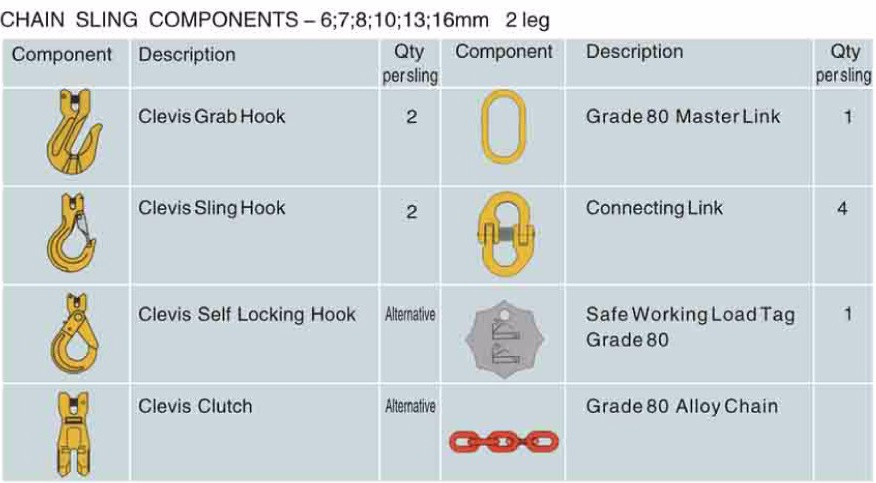

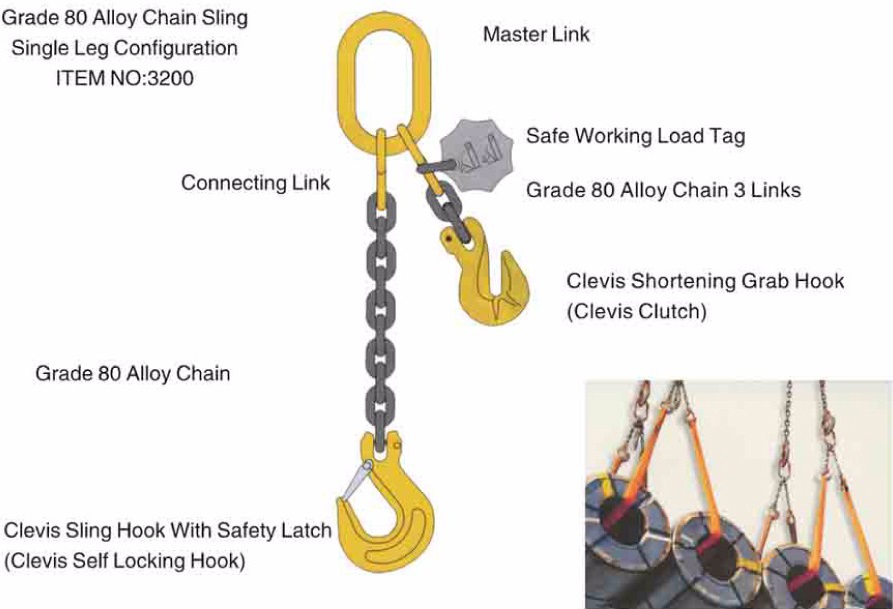

Chain slings are made from high strength alloy steel made specifically for the lifting industry. They have numerous configurations and end fittings. Standard slings are available in two grades of steel: Grade 80 and Grade 100. are the most rugged slings available.

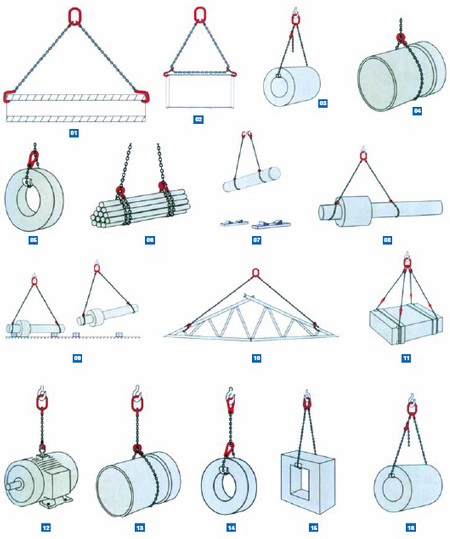

They are the classic and widely used load handling attachment for a wide variety of lifting applications. They feature flexibility and extremely high durability. Their relatively high deadweight is offset by the use of improved materials with maximum strength

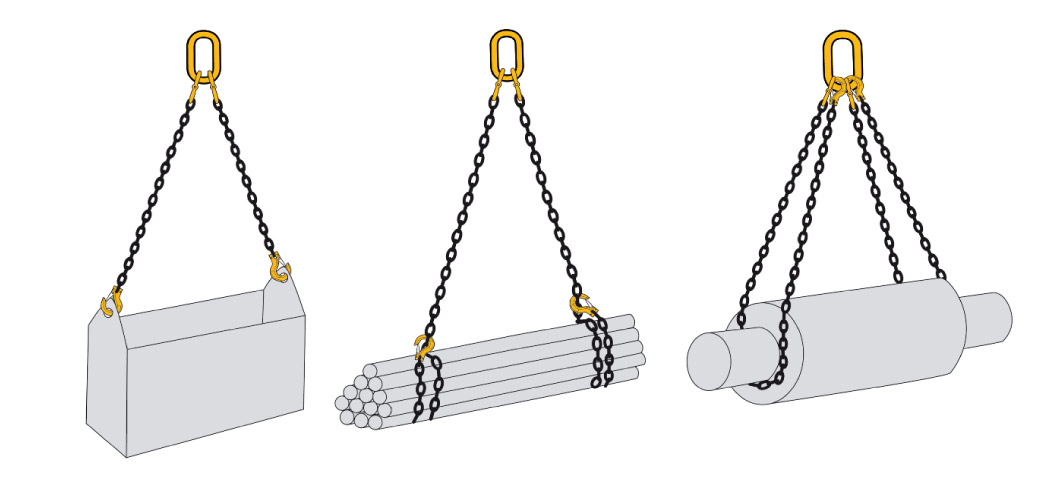

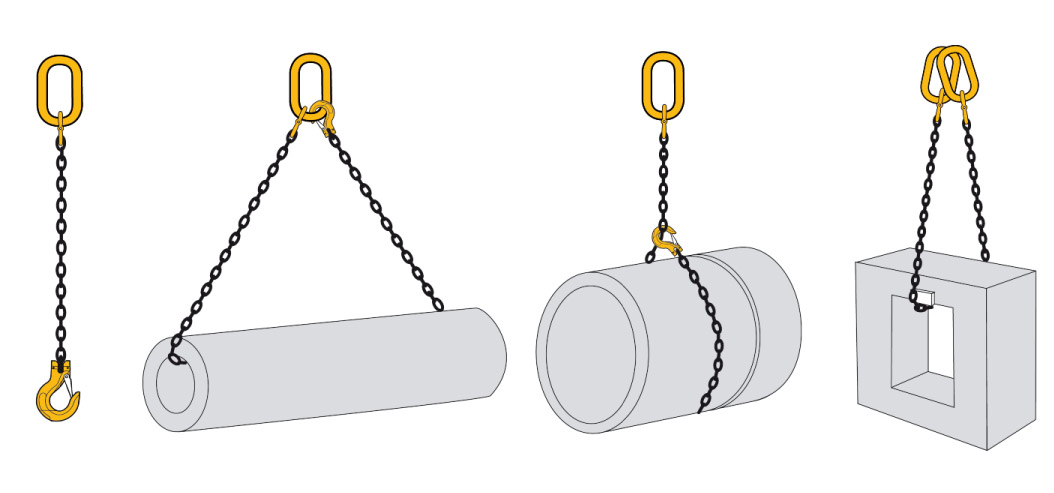

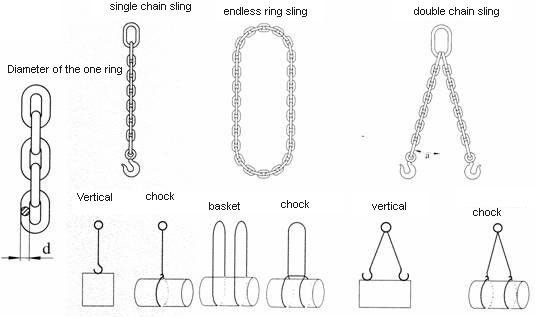

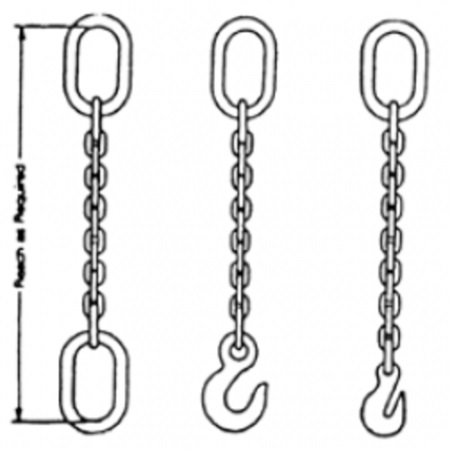

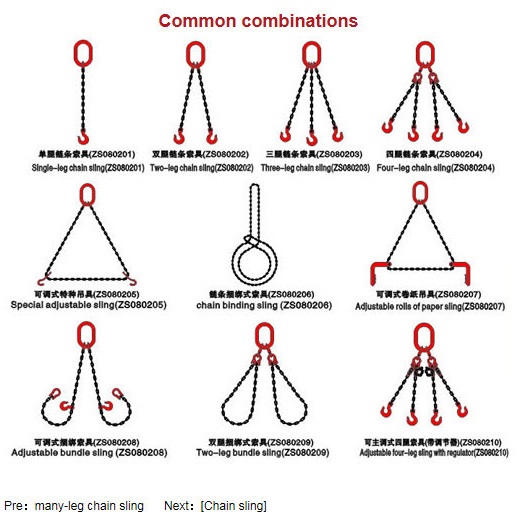

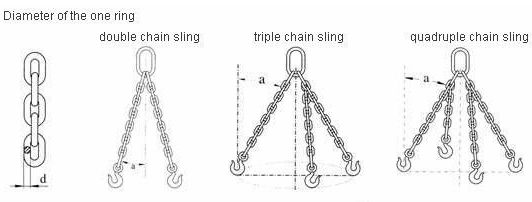

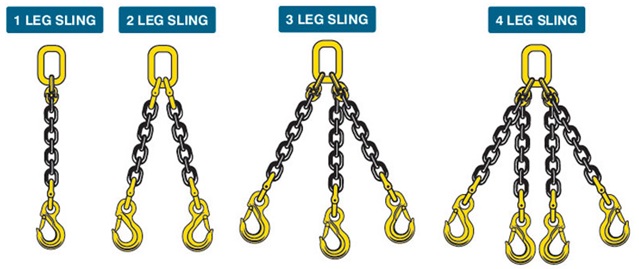

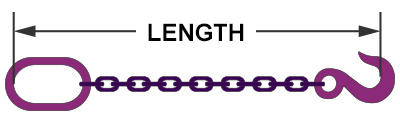

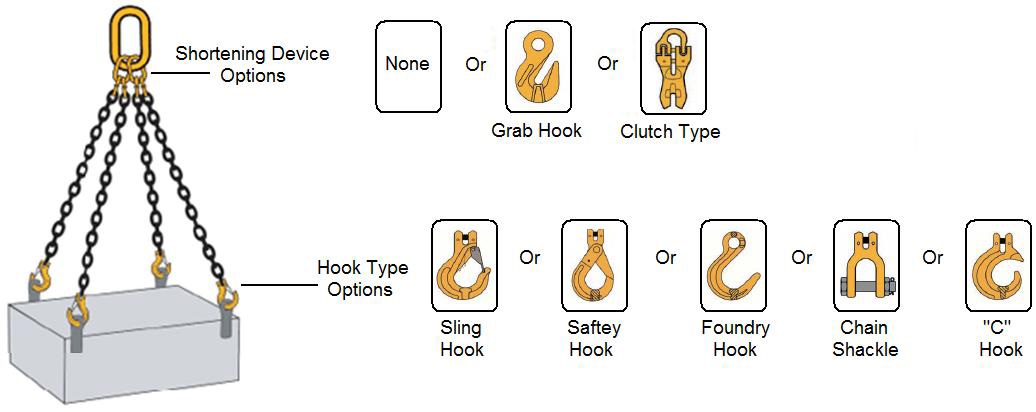

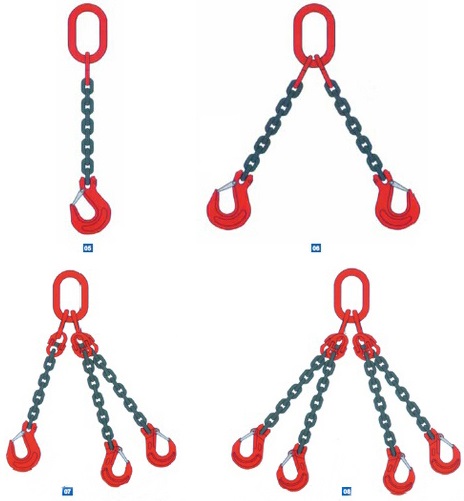

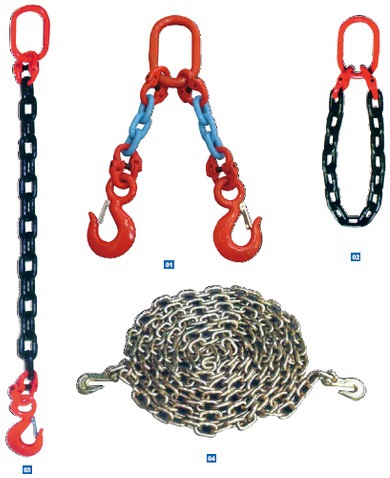

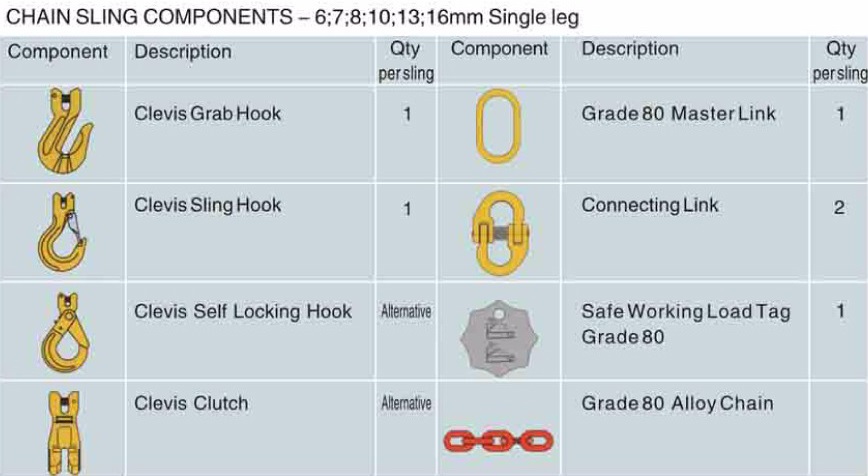

They come in single, double, triple and quadruple legs for all of your lifting needs. There is also an endless grommet style alloy chain sling available. Additionally, They are available with many different type of hooks like alloy sling hooks, alloy grab hooks, alloy J-Hooks, Alloy Self Locking Hooks, or Plate lifting hooks. Each legged sling comes in a variety of hook types, chain sizes and lengths.

Alloy steel chain slings are made from various grades of alloy, but the most common grades in use are grades 80 and 100. They are among the most important pieces of equipment that rigging supervisors rely on to perform safe lifts. In addition to being more than capable of getting the job done, They also have a reputation for being durable.

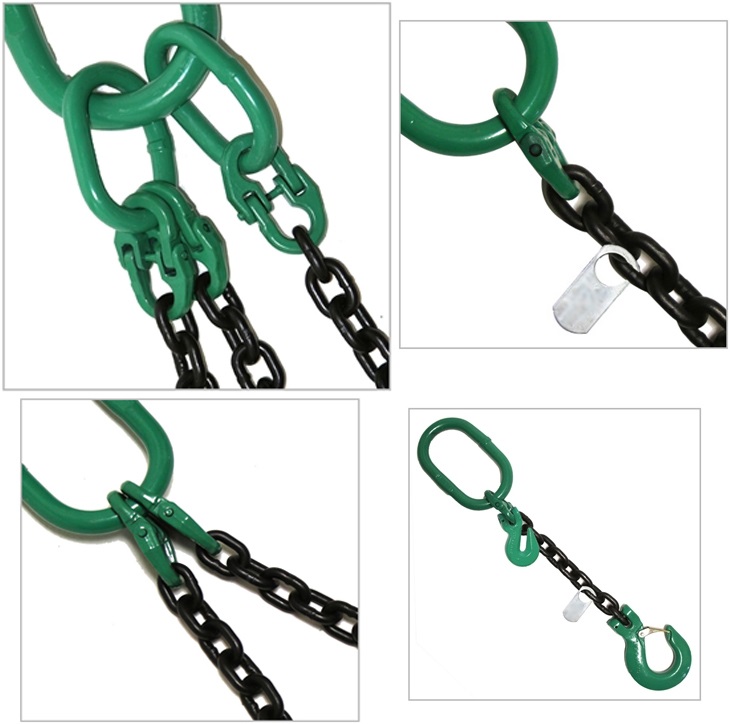

A good chain lifting sling can last for decades before needing replacement. The chain provides strength and ruggedness to withstand harsh working conditions. It is ideal for harsh environments, An alloy chain sling will tolerate a wide range of temperatures; however, compared to other types, it is relatively expensive and, depending upon the grade of alloy chain used, relatively heavy. It is the most durable type of sling and is easily repaired in the event of damage. Slings include a tag that shows chain grade and size, length, and capacities in each configuration. Grade 100 steel slings are approximately 20% stronger than grade 80 steel. Chain Slings.

Resistant to abrasion and cutting. Welded version offers the security of tamper-proof assemblies. Can be repaired, proof tested and recertified. They preferred for use in the most rugged conditions. May be used at rated capacity at temperatures up to 400° F.

They are among the most important pieces of equipment that rigging supervisors rely on to perform safe lifts. In addition to being more than capable of getting the job done, they also have a reputation for being durable.

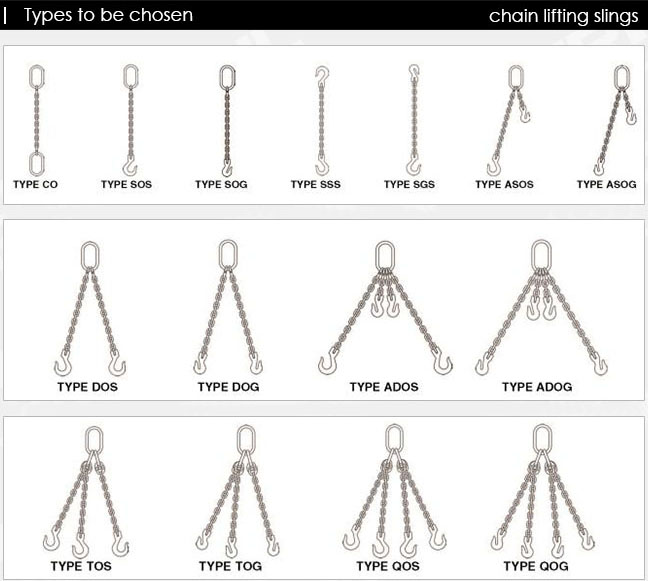

Alloy chain slings are the most durable type of sling and is easily repaired in the event of damage. They are typically designated by a three character symbol based upon the number of legs and types of components used in the assembly.

Steel chain slings are regulated under the MIOSHA Part 49 Slings. It can manage heavy loads from steel beams to marine engine blocks. Chain sling options include strength-enhancing qualities such as double welds, Grade 80 and Grade 120 steel alloy, or Grade 50 structural steel for high-temperature use. Only alloy steel chain, grade 80 or 100 is to be used for overhead lifting. Alloy steel chain will stretch when over loaded; other types of steel may break without warning.

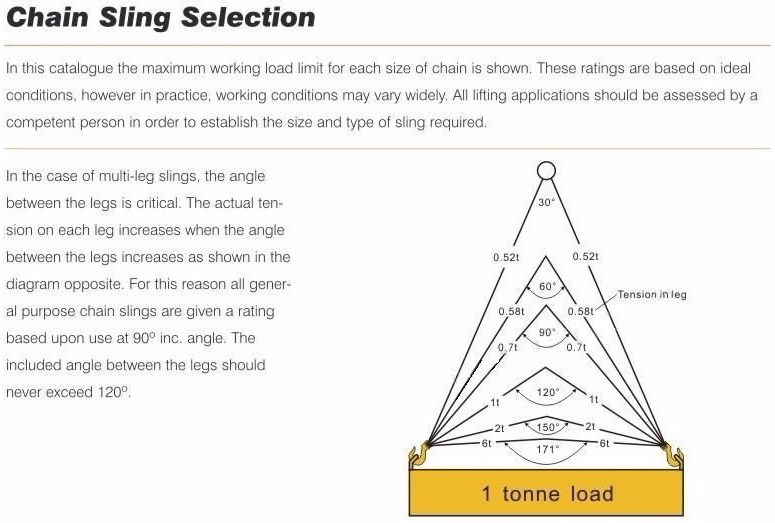

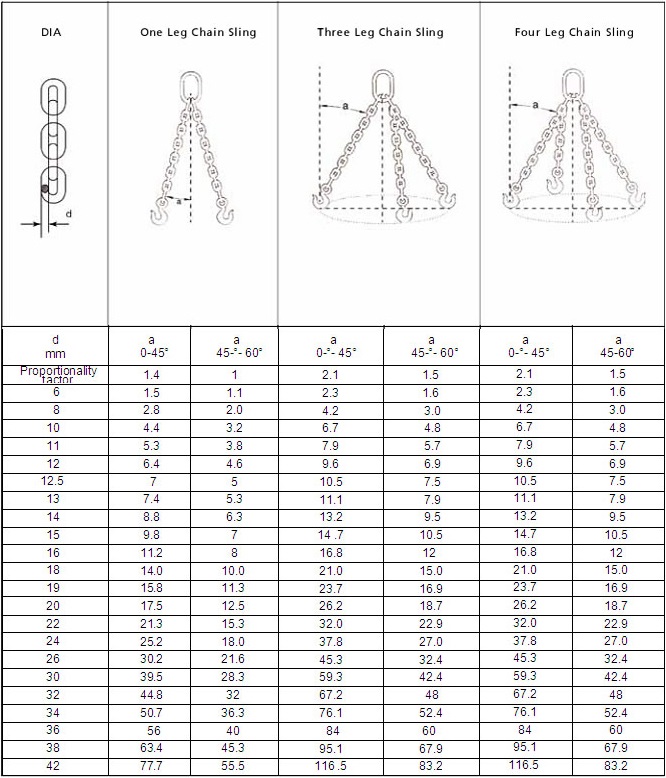

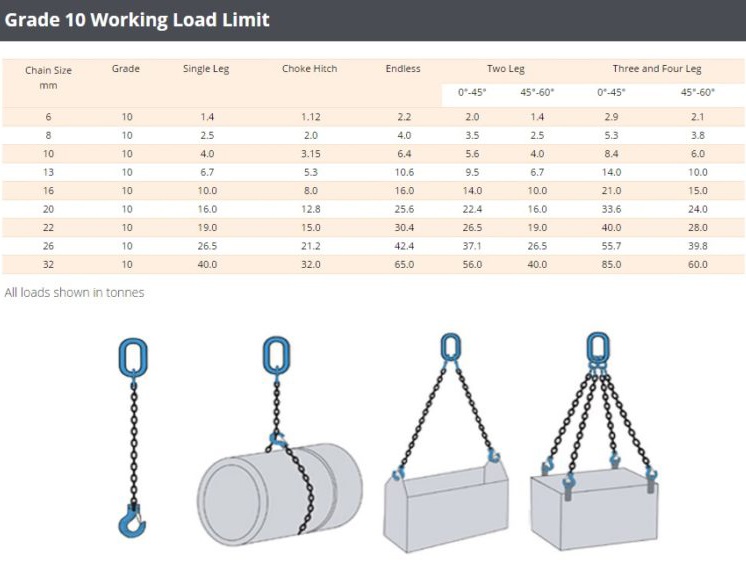

The leg at 60 degrees actually sees 1.15 times the weight of the load, at 45 degrees it sees 1.41 times, and at 30 degrees it sees 2.0 times the weight of the load on each leg. This is why an alloy chain sling should never be used at a lifting angle below 30 degrees.

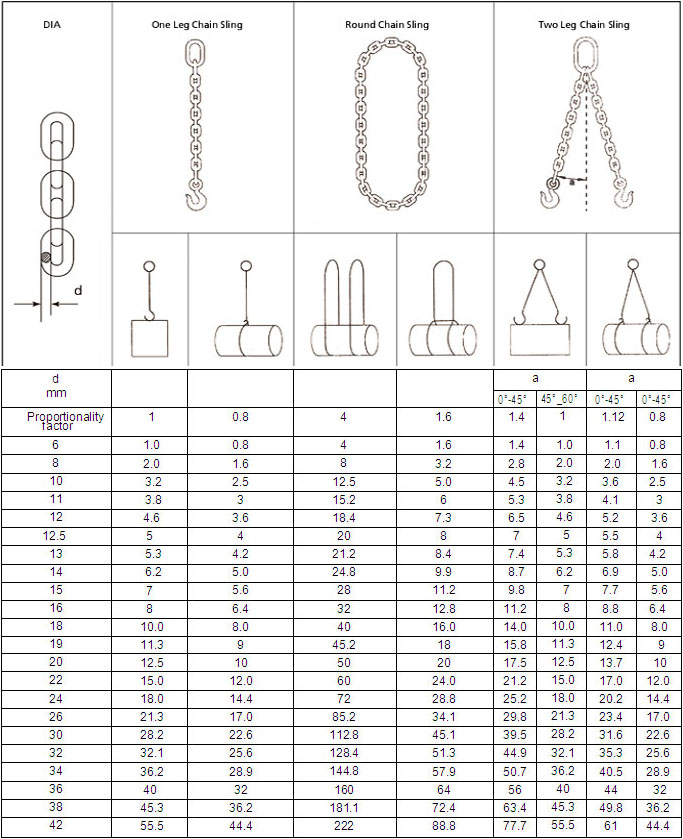

Using the maximum load (or loads) you will lift, and the angle of lift required—work to the left across this table to determine proper chain size for your sling. The working load limit of it and components is established as pounds applied at the indicated degrees from horizontal. They are completely customizable to fit your specific industrial needs.

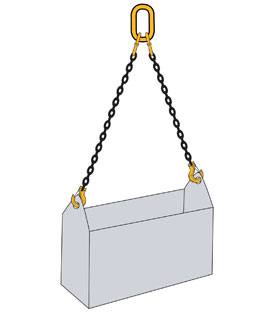

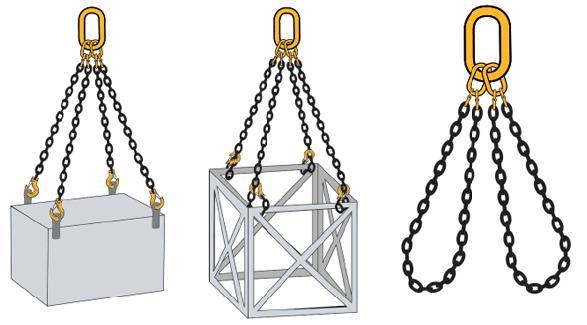

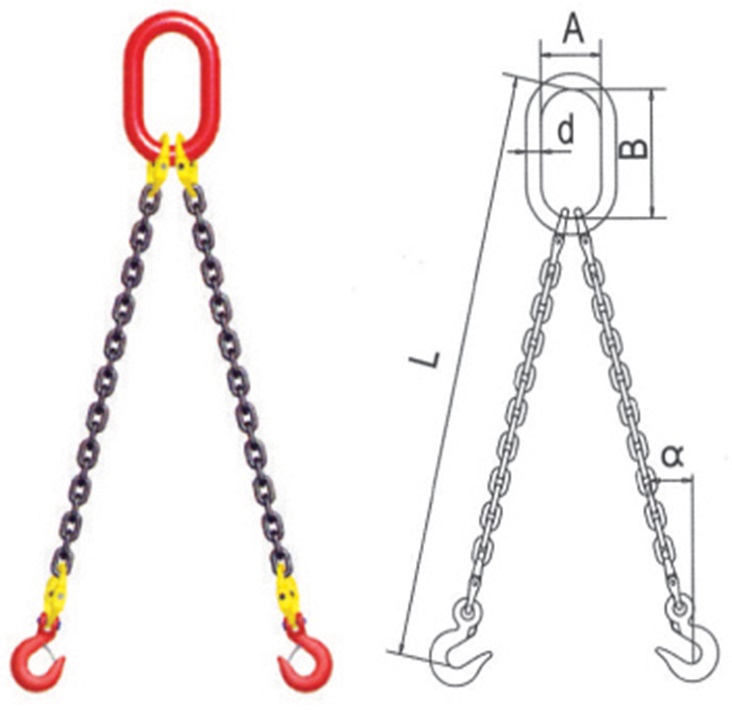

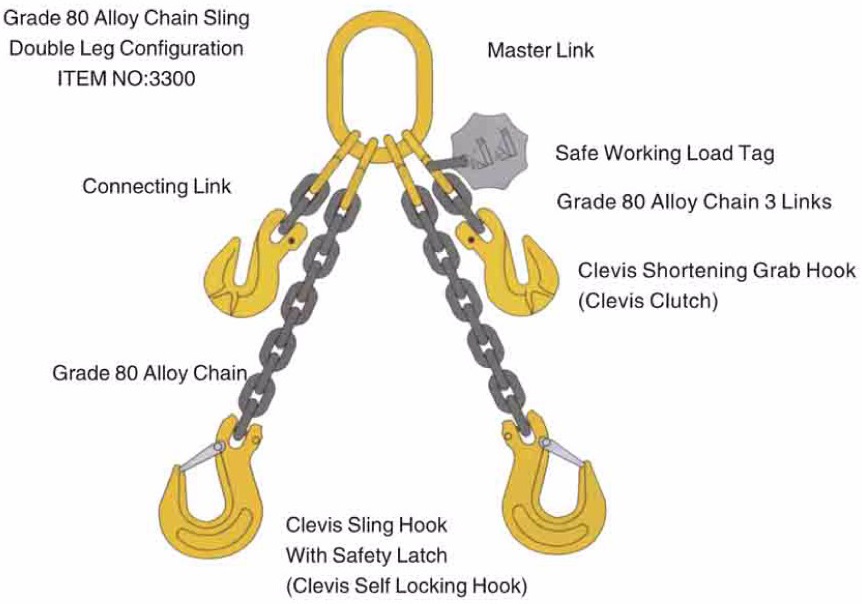

Chains have been the go-to in a variety of uses because of their durability and reliability. A double leg chain sling (also called a 2 leg chain sling) is comprised of two lengths of single leg chain attached to an oblong at the top. Fittings of your choice at each bottom end. Double leg chain slings offer higher work load limits and improved load stability for overhead lift applications. Two pick points also increases its versatility.

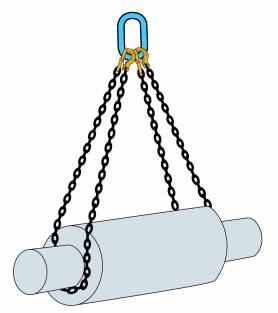

Triple legged chain slings feature 3 legs and are made of a master ring attached to couplers, which are then attached to chain and hooks. They are built with or without grab hook adjusters and are available in grade 80 or grade 100. Often called a three way chain sling, it works well when multiple grab points are needed.

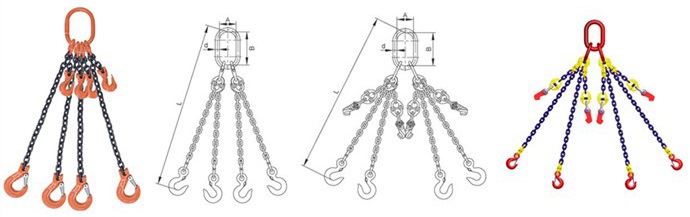

A quad branch chain sling, especially when used on a load of rigid structure, is usually not sustaining the load evenly distributed on each of its four branches. The maximum working load limits are therefore set at the same values as for triple branch chain slings of equal quality and size and used with branches at same angle of inclination. In addition, quad leg chain slings offer higher Working Load Limits, four pick points and greater load stability for overhead lifting.

When it comes to heavy lifting, there are many different types of slings that can be used. One of the strongest slings, however, are chain lifting slings. We have a variety of it, including single-leg, double-leg, three-leg and four-leg slings that are made from super strong, grade 80 or 100 alloy steel. From adjustable to self-locking, you can find the right tool for your project. Build your chain sling by choosing from master link, grab hook, and slip hook fittings in a variety of chain lengths.

Our Traditional ones are the cream of the crop when it comes to the durability and security they bring to your load lifting. That’s why they’re used by industries worldwide.

A competent person must also inspect chain lifting slings periodically, and at least once a year. Inspection frequency is based on how often the sling is used, the types of lifts being performed, the conditions in which the sling is being used, and past experience with service life of similar slings and usage, For safe use, our site offers recommendations to use them in the proper way.