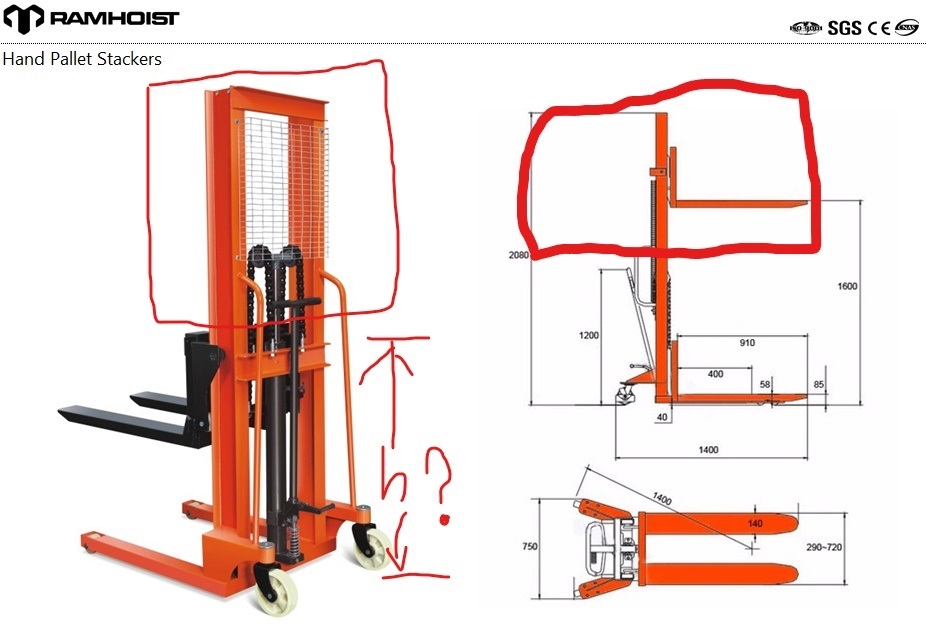

Modification of 1 Tone Wide leg stacker from New Zealand

Keyword:1 Tone Wide leg stacker Time:2021-5-8 21:46:20

| Message Subject | Inquiry about 0.5 Ton to 1 Ton Mini Hydraulic Hand Manual Pallet Operated Stacker |

|---|---|

| Message Content | Hi Ramhoist Can you send me some details with dimensions of this product? (with wide legs, not the short legs) I need the wide leg stacker to move the AC units purpose. but I have to do some modification on the fork section, So I need details to meet the requirements. Also, can you give me more information about the shipment to New Zealand? Regards, Jason Zhou 07/06/2019 |

| Inquired Product |

|

Appreciate that!

At last, Can you send me some dimension range of fork section of option A.

RAMHOIST:

2.We want to know the road condition from the train to the maintenance workshop.Because the wheel of electric truck is relatively small, if there re wide or deep gaps or rail or other barriers on the road, it might be a problem for our truck to go through.The forklift you used however don't have this kind of problem, because they have large wheel. Please show us some pictures of the road conditon if possible.

Customer: As our discussion went properly, I have a new problem :Can you guys cut the frame in half of the mast?the figure shows the request:

I want cut the frame where shows in red rectangular, in other word I only want 1 meter high in total height. because the 2080 mm mast will damage the train body and the unit only need to be lifting to 500 mm height above ground. And I want to know the height of the hydraulic cylinder h? the size of the Unit are :

HVAC unit specifications:

Length 2499mm

Width 1850mm

Height 500mm

Weighs 644kg.

Material casing Painted galvanized mild steel.

RAMHOIST

We will do some amendments based on this stacker. 1. Change the mast to 1meter height. 2. Change the fork to 1.85meter length (according to the size of AC unit) and the width between two forks to 0.7m, in order to fit the distance between two holes on the AC unit. The purpose to make the long fork is to leave enough space between the stacker and the train body. To lift the AC unit, you do not need to put the whole fork into the hole, just a part of it. In this way, there will be a safe distance between the stacker and the train body.

The fork will be similar as this.

Electric stacker is ways better than manual stacker, considering the fact of your jobs. You need to move a lot of AC units, not just one or two. Manual stacker need to lift the goods by manpower, which is only suitable for some easy lifting job, not like your regular ones. It’s not possible for you to use a manual stacker to do this kind of job all day long. So the electric stacker will be the better option for you.

Customer: Thanks for the information which you providing. As our discussion, we decide to keep the Manual hand jack stacker as the first priority. And we will have a further discussion about your ideas.

Customer: Sorry for the late response, I just finished my vacation and will talk to the manager tomorrow. But we had discussed this before. I want to konw what is the longest length of forks you can provide and the length of the legs( Are the both legs are the same length as forks?) Also can you fabricate the mast of the stacker to 1 meter? and I want to know the total overall price and the period of shipment to New Zealand?

RAMHOIST: What is the longest length of forks you can provide and the length of the legs ( Are the both legs are the same length as forks?)

According to the size of the AC unit (2499*1850*500mm) and specifications of the stacker itself, we suggest the suitable fork length should be 1850mm. Legs and forks will be similar as below picture.

Also can you fabricate the mast of the stacker to 1 meter? and I want to know the total overall price and the period of shipment to New Zealand?

The mast can be 1 meter.

Goods will arrive NZ around 60-70days after the placing of order.

Why choose Electrical Stacker not manual one?

1. The size of AC unit is too large for manual stacker. If we add the fork length of a manual stacker to 1850mm, it will be unstable and will fall down if loaded. Because the weight of stacker itself is too small and can’t keep the balance when loading. The legs won’t help in this case. Think about the diesel forklift you used, if its weight is to be half or one-third of current figure, it can’t keep balance at all.

2. Manual stacker need to lift the goods by manpower, which is only suitable for some easy lifting job. We know how much power it takes to lift cargo up, it’s not possible for you to use a manual stacker to do this kind of job all day long.

If everything works out properly, we may start ordering in this month. So I need these dimensions.

RAMHOIST: According to your requests and working condition, if you want to take manual stacker, it means to develop a brand new model, not just some modifications. Because the AC unit you're going to handle is not suitable for manual stacker at the beginning. If you insist on taking manual stacker,we would need a MOQ of 50pcs, considering the low value of manual stacker, and great time and effort that should be spent in this job.If you okay with electric stacker,it will be no problem for you take 1pcs sample.

RAMHOIST: Already checked with our engineers about the fork and legs and all of them think those modifications are not workable. The weight of manual stacker is around 200-300kg, even less than the AC unit itself. If we add a long fork to the manual stacker for example 1.85m, the centre of gravity will move forward and the stacker will fall when loading. Even the long balance legs won't help in this case. Normal fork length for a manual stacker is only 1m, in order to keep it stable. Please think about the diesel forklift you used, they are equipped with counterbalance device to keep stable. But stacker don't have this device, so the weight of itself is the only thing that she can rely on to keep stable. That's why an electric can be modified, but a manual stacker can't, because the former one is more heavier.