Inquiry about 10t coil tipper from Indonesia

Keyword:10t coil tipper Time:2023-8-6 16:02:08

Inquiry Product

|

Message Content

Dear Sirs/Madam,

I am Juju from PT. ********* - Indonesia

We need coil tipper for our factory

Attached is our Coil Tipper specification.

Specification is as belows :

Coil Weight : Max. 10 t

Coil width : 800 – 1250 mm

Coil diameter : dia. 800 – 1650 mm

Drive : 3 Kw motor reduce

Thank you for your attention and cooperation and we are looking forward for your reply.

Best Regards,

Juju

RAMHOIST: 6600 USD (platform size: 1700mm*1700mm, V-bed on one side and flat on other)

Instruction manual: http://ramhoist.com/Lifting-Handling-Equipments2/3990.html

technical specification is as blow:

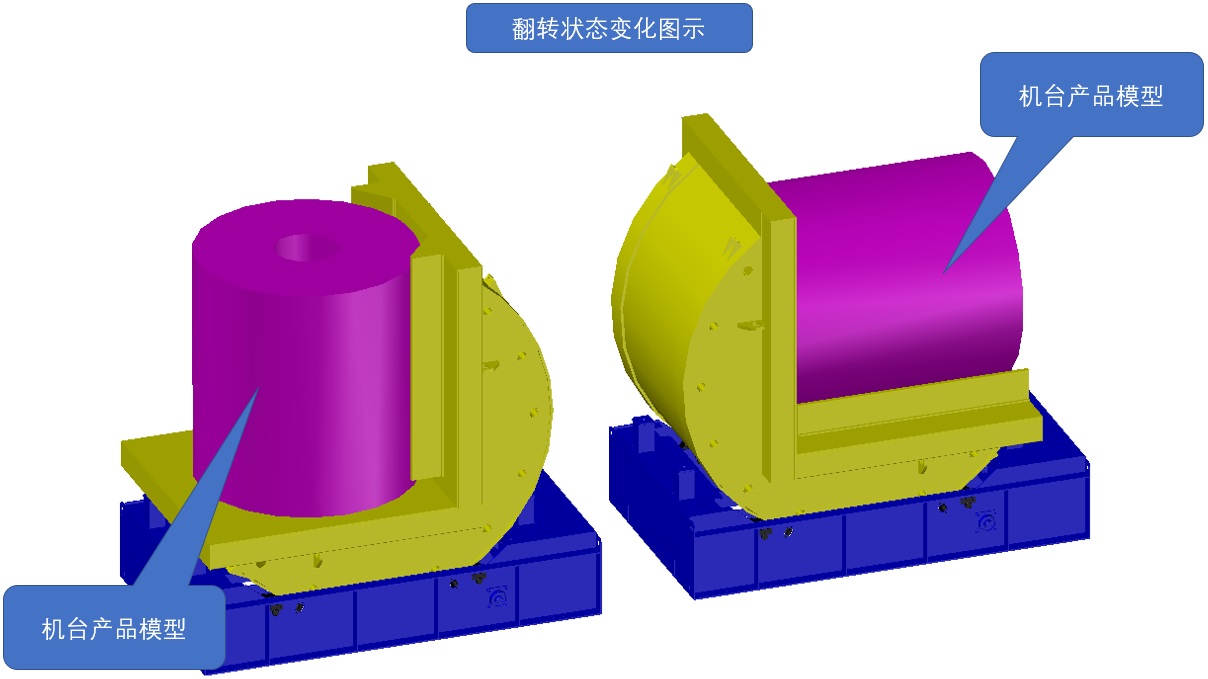

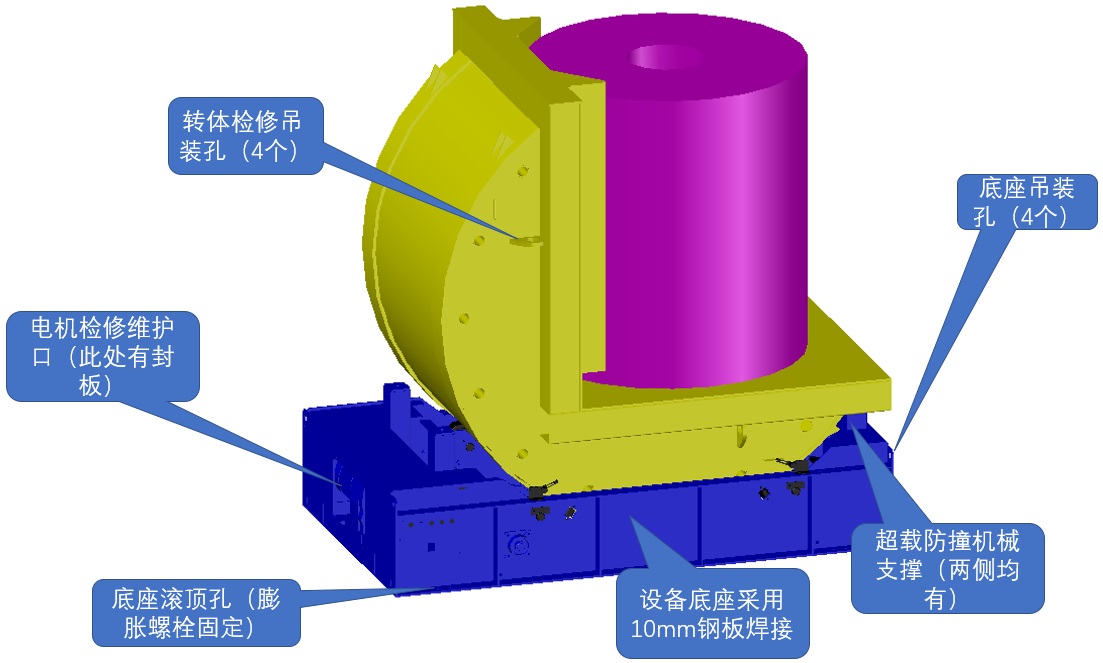

1. Product shape and structure:

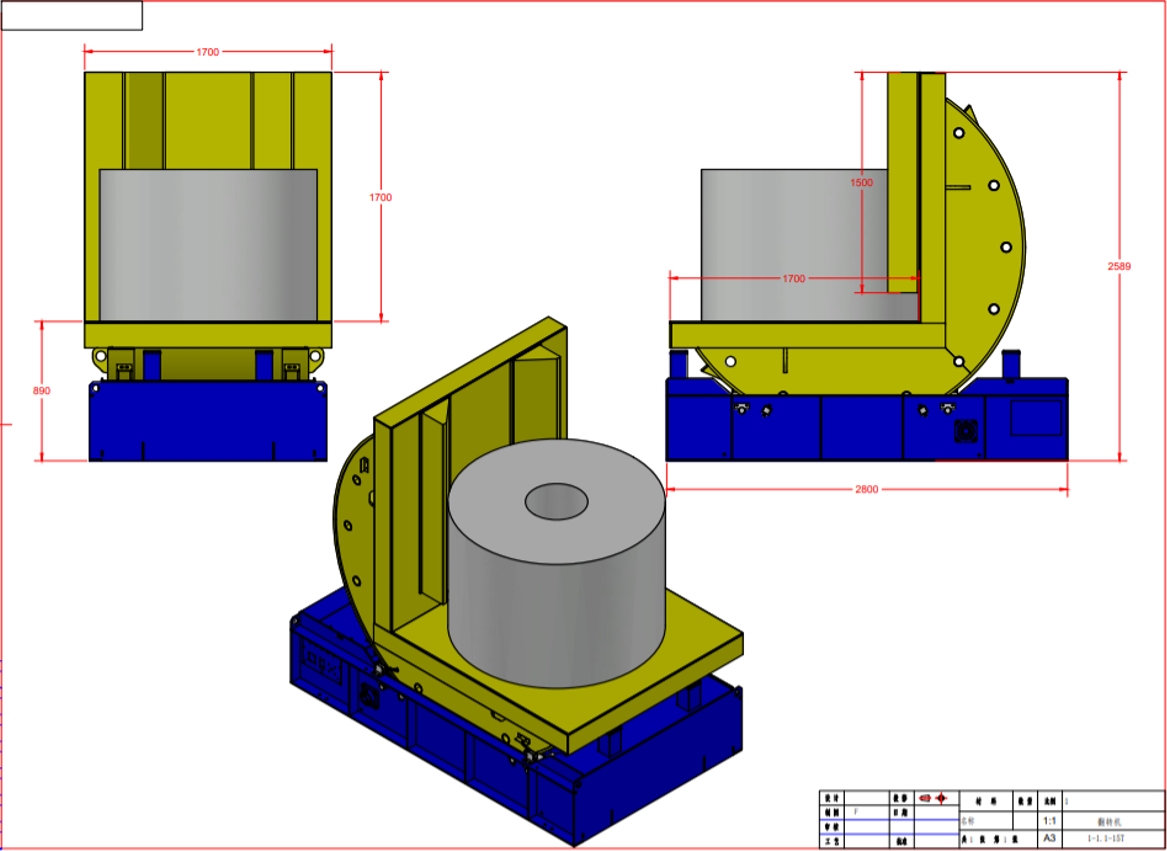

2. Product Size:

Body size: The machine table is 1200×1400, and the pallet slot is tentatively reserved for 200 (this size is reserved according to the customer's actual pallet size)

Height:2589mm

Length:2800mm

Width:1700mm

Length of V-bed:1500mm

Distance from table to ground: 890mm

N: 1300mm

T: 145 degree

P: 0mm

P1: 0mm

The base of this equipment is 10mm steel plate welding and the surface contact area of ground is stable. Do not need an additional foundation, The length of the equipment is 2800mm, width is 1700mm. The size is less than 3000mm × 1800mm

3.Product features

1). The mechanical overturning system is equipped with a braking system, which is self-locking when the machine is stopped or powered off, and there will be no overturning phenomenon.

2). Four idler mechanism to ensure the smooth operation of the equipment.

3). Multiple limit protection to ensure safety.

4). Hard tooth surface industrial reducer, stable operation.

5). The parking brake self-locking function can stop at any position, and the flip body is locked in place, which is safe and reliable.

6). The control system adopts 24V safety voltage and wireless remote control to ensure the safety of personnel operation.

7). Adopt leakage protector and overload circuit breaker to effectively prevent potential safety hazards caused by leakage and overload.

8). Simple operation (wireless remote control) The control box is built-in body type, the body is sturdy and durable.

9). Safe, stable, fast and convenient.

10). The product has passed ISO9001 system certification.

4.Technical parameter:

Model | FZ10T |

Max load bearing | 10T |

Power of motor | 4KW |

Turnover speed | 0-45s±10% |

Transmission mode | Mechanical drive |

Reduction ratio | 1:126 |

Table size | 1700mm*1700mm V-bed, 1700mm*1700mm flat |

Mode of operation | Independent control/Wireless remote control |

Deadweight | About 4.5T |

Max turning angle | 90° |

Voltage | 380V 50HZ 3Phase 4line (三相四线) |

5.Main electrical equipment:

Name | Brand | Model |

Reducer | JUNQING | SR97 |

Contactor | DELIXI | LC1D18 M7C |

Circuit breaker | DELIXI | C32N |

Thermal protector | DELIXI | JRS1Dsp-25 |

Wireless remote control | YUDING | / |

Emergency stop switch | SCHNEIDER | XB2-BS542 |

Start button | SCHNEIDER | XB2-BA31 |

Indicator light | SCHNEIDER | AD16-22D/S |

Travel switch | MOUJEN | ME-8108 |

Terminal block | TEND | TBR-10 |

Chain | ZIQIANG | 1.0 |

Bearing | HRB | 62122RS |

5. Energy and work requirements

1. Working system: The three-shift production system can operate continuously for 24 hours for 8 hours per shift.

2. Working environment: -10-40 degrees Celsius, working temperature: 10-60 degrees Celsius, relative humidity 10-90%.

3. Power supply requirements: The input power supply of the equipment is three-phase four-wire AC380V-50HZ.