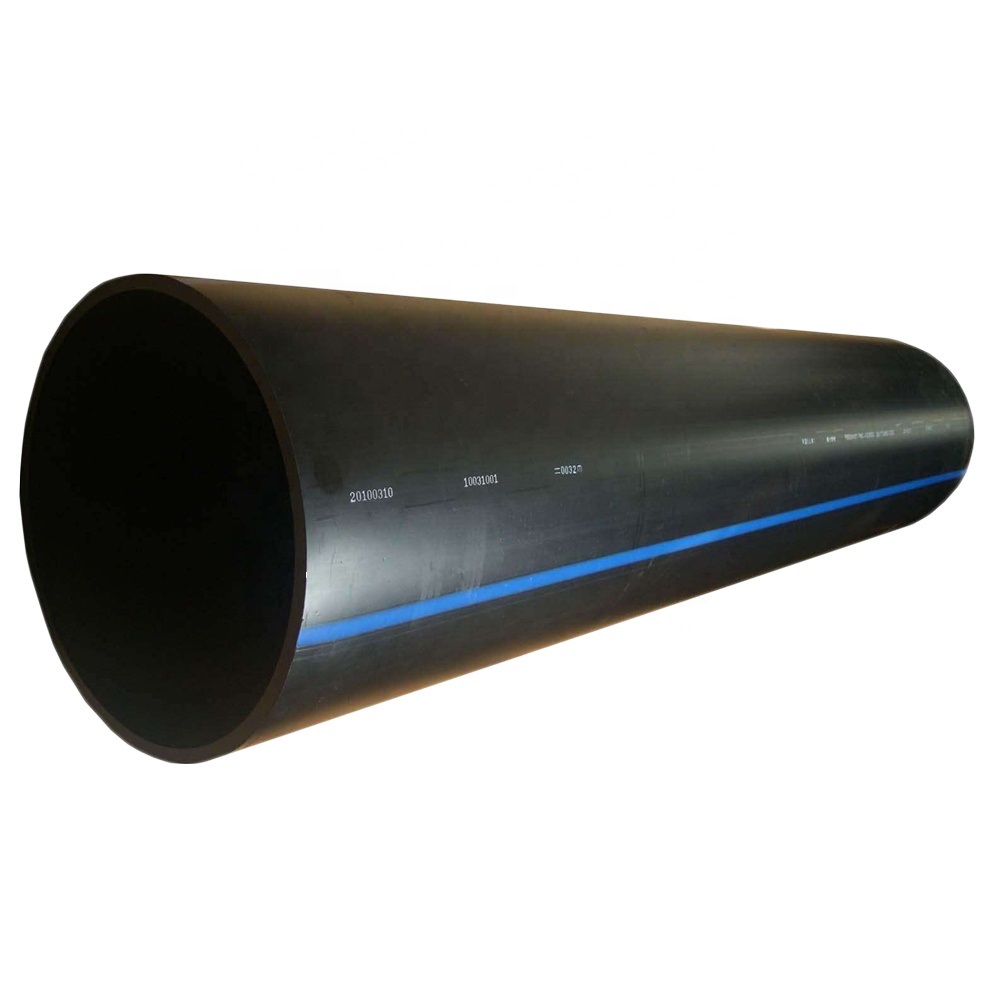

China professional customized high density water HDPE Pipe with high quality

Keyword:HDPE Pipe Time:2019-6-17 23:29:49

Material: high quality PE80 or PE100

Size: 20mm to 1600mm

Thickness: 2.3-61.2mm

Pressure Rating: 0.4Mpa,0.6Mpa,0.8Mpa,1.0Mpa,1.25Mpa,1.60Mpa

Color: black,blue or other colours on request

Connection: socket fusion joint,butt fusion joint,electro fusion joint,flanged joint

Product Overview:

HDPE pipe with spirally enwound structure-wall has large diameter, capable of withstanding heavy load and assuring zero leakage! It is a new type of "green" sewer and drain pipe, which is safe and environment-friendly.

It is a type of profiled structure-wall flexible tubing, which has a smooth inner wall, a spiral stiffening rib as its outer wall, and rib interface is manufactured via O-type spiral winding technology. As it is safe, reliable, and environment-friendly, the product has been widely used in fields such as municipal works, nuclear power and thermal power plant, petrochemical industry, metallurgy and transportation hub, and has also been extensively applied globally for a long time. In China, it has been rated as a key promotional product by Ministry of Construction, and is a new type of high quality product in the national promotion of "substitution of steel by plastic, substitution of cement by plastic" for urban rain & sewerage system.

Welding skill

1. Material preparation: Place the pipe or pipe in a flat position and place it on the docking machine, leaving enough 10-20mm cutting allowance.

2. Cutting: Cut the impurities and oxide layer on the end face of the welded pipe and pipe fittings to ensure that the two pairs of ends are smooth and free of impurities.

3. Alignment: The end face of the two welded pipe segments should be completely centered, the smaller the wrong edge, the better, the wrong edge can not exceed 10% of the wall thickness.Otherwise, the docking quality will be affected.

4. Heating: The docking temperature is generally between 210 ºC and 230 ºC, the heating time of heating plate is different in winter and summer, and the melting length of both ends is 1-2mm.

5. Melting docking: It is the key of welding. the docking process should always be carried out under melting pressure, and the crimping width should be 2-4mm.

6. Cooling: Keep the docking pressure unchanged and let the interface cool slowly. the cooling time is stiff by touching the crimping edge by hand, and the heat is not felt.

7. Docking completion: After cooling, loosen the slip, remove the docking machine, and re-prepare the next interface connection.

Using high quality materials, strict control, non-toxic material, no breeding bacteria, fundamentally ensure the quality of the pipeline.

High density injection HDPE Pipe fittings

1. They are used for connecting pipes of all specification which have the same materials and the same SDR system

2. They possess reliable connectivity, high interface strength, good airtight performance, and stable welding performance.

3. They are easily welded and operated, and conveniently used.

4. They are not easily affected by changes in environment temperature or human factors.

The picture of the HDPE Pipes’ fittings

Although HDPE Pipes have been successfully applied in many fields, there are still several points to be noted in the use process:

1. The welding: Hot melt connection, the temperature must be to 210 plus or minus 10 ℃, should pay attention to avoid the fire burning.

2. Buried: In the pipeline work, must consider the necessary safety measures.

3. Test: Water is recommended as the pressure test medium. During the test, measures should be taken to prevent pipeline movement or damage.

4. Positioning: The polyethylene material cannot be controlled by the magnetic positioning equipment. Other methods can be used to detect the polyethylene pipeline, including tracing line, marking belt, testing belt, marking line, electronic marking system and voice control pipeline tracing method.

5. Air pressure: HDPE Pipe cannot be used in high-pressure gas conveying field.

7. Static: HDPE pipe mixed with high static, in flammable and explosive gas occasions, should take the corresponding measures to eliminate static.

9. Winding: The small diameter HDPE pipe of winding has energy stored like a spring. If the packaging belt is cut open, it will generate greater resilience.

11. Weight: Although the HDPE pipe is lighter than other traditional pipes, it still has a certain weight. Therefore, care should be taken in handling and construction.