Description of Load by Vacuum Stone lifter and Composition of Manipulator

The vacuum generator used by vacuum stone lifter manufacturers is rubber suction cups or foam suction cups. The material can be silica gel, fluorine rubber or foamed rubber, nitrile rubber or natural rubber. There are many kinds of vacuum lifters. Vacuum lifter hanger is a kind of vacuum hanger which can lift large steel plate, glass, aluminium coil, slate and other objects. It consists of lifter and other main components. There are also many people who call vacuum stone lifter hanger lifter, or vacuum lifter. Because of its attractive suction cup, the material used in the suction cup is very important. In engineering practice, there are a lot of unstable and asymmetric cyclic loads on vacuum lifter. In each stress cycle, the average stress is observed. And stress amplitude D. It's constantly changing.

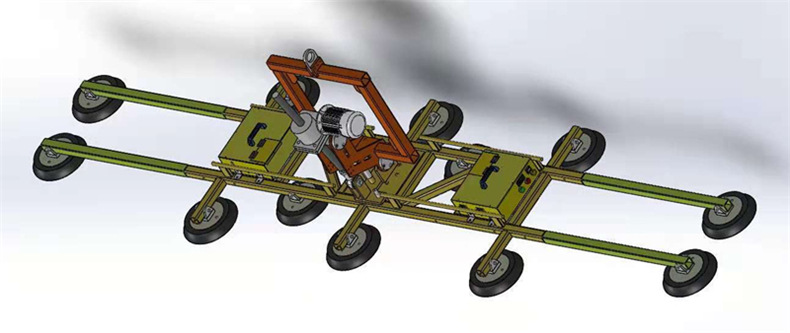

Therefore, in order to carry out fatigue design of parts under unstable and asymmetric cyclic loads, it is necessary to determine the load spectrum of the parts under various typical working conditions as the basis for analysis and calculation. However, the actual working conditions of all kinds of stone lifters are various, some of which have strong regularity, others are disorderly and changeable. Therefore, it is necessary to select some typical working conditions, carry out statistical analysis on the basis of actual measurement of its load, gather the results according to a certain regularity, and with the frequency of various working conditions, the load spectrum of vacuum lifter can be obtained. Vacuum stone chuck manipulator is composed of light structural steel pipe components, vacuum chuck, vacuum, electromagnetic control valve, vacuum switch and other components. Because the manipulator is designed strictly according to the requirements of workpiece and user, the standardized mechanical connection interface is adopted in the design, and the special vacuum lifter of the manipulator can be suitable for various workpieces.

Enterprises have accumulated rich experience in the design of manipulator in practice. The designed manipulator can completely match the plate, and can connect with the robot without any problem. It has high rigidity and plate conveying accuracy. Because the arm of the manipulator is made of steel tube structure, the weight of motion control clutch, connector and horizontal tie rod is reduced a lot, which further improves the motion performance of the manipulator, and adheres to the elastic jitter in the process of acceleration and deceleration of plate workpiece transportation.

Vacuum stone lifter is undoubtedly one of the products with more demand in mechanical fittings. There are many kinds of stone lifter for manipulator, and the materials and processes of manufacture are also different. So, how do we choose the manipulator? The material requirements of the stone lifter of the manipulator are also varied. Some of them work at high temperature, they need high temperature resistant silicone rubber and other blanking, this material is also easier to grasp rough workpiece. The side made of polyurethane material is durable and wear resistant. Because of the different production environments, there are many criteria for the selection of stone lifters. For example, various related physical parameters, such as friction coefficient, suction size, lifter radius, etc.

- No information

-

1. Design objective of electronic crane scale network management. (1) Adopt advanced distributed data processing techno…

-

Electronic crane scale bearing platform installation to focus Electronic crane scale can be installed generally on the li…