Cautions for Vacuum glass lifter in Use

Keyword:Vacuum glass lifter Time:2019-11-5 9:52:27

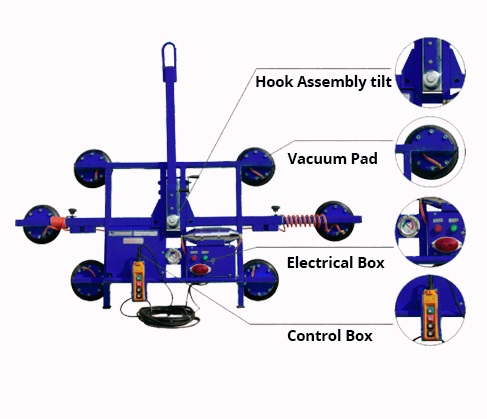

Vacuum suction cup has great breaking force, so it is widely used in various vacuum suction equipment, such as construction, paper industry, printing, glass and other industries, to achieve the task of sucking and transporting thin and light goods such as glass, paper and so on. Vacuum chuck has the characteristics of simple structure, convenient installation, beautiful appearance and strong suction force. After using vacuum glass lifter in practice, the following points for attention are put forward for the use of vacuum glass lifter:

1. It is strictly forbidden to exceed 40% of theoretical suction force when using vacuum glass lifter to suck and carry heavy objects, in order to prevent overload and heavy objects falling off.

2. Vacuum pressure must be kept stable during use.

3. If the glass lifter fails due to aging, the new vacuum glass lifter should be replaced in time.

The main shaft motor contactor KML of vacuum glass lifter is realized in the coil circuit driven by KM of the motor contactor of cooling pump, whose working process is as follows.

1.Turn on the power supply and close the power switch Qs.

2. The motor M1 starts and presses SB2, the Kml coil is energized, the main contact of Kml is closed, and the normal auxiliary contact of Kml is closed and self-locked, and M1 starts and runs continuously.

3. When the motor M2 starts in the running state of ML, press SB3 and KM2 coil to turn on electricity, the main contact of KM2 is closed, and the auxiliary contact of KM2 is closed and self-locked. The M2 starts and runs continuously.

4. When the motor M1 and M2 stop at the same time while the motor M1 and M2 run at the same time, press the SBl, KMl and KM 2 coils lose power at the same time, the main contacts of KMl and KM2 are disconnected, and the motor M1 and M2 stop running.

The control circuit of starting and stopping the motor sequentially. The control circuit of the motor M2 of the vacuum hanger is connected in parallel at both ends of the coil of the contactor Kml, and then in series with the self-locking contacts of Kml, which ensures that only when the Kml is electrically sucked, after the motor Ml is started, the KM2 coil can be electrically charged, and the M2 can be started, so as to realize the control requirements of starting Ml first and starting M2 later. M1 and M2 stop at the same time.

There are two ways to input the vacuum glass lifter signal in the machine tool control panel, one is to input the NC part through the I/O logic module, and then to the PLC part for processing; the other is to input the input/output module directly from the PLC part to the PLC.

Logic module (6FXll24-6A). Logic module does not belong to the product scope of Siemens 3 system. It is the I/O module of Siemens 810/820 system. In Siemens 3 system, only the input signal of machine tool control panel (J85) or a small amount of I/O signal of machine tool operation are processed. The module has three ways as follows:

64-point input, 24V DC. 2, 24-point output, 0.5A, 24V DC. Input at 8:00, 0.1mA, 24V DC.

Siemens 3 system control panel can connect up to two logic modules.

PLC part

Siemens 3 system connects independent PLC and uses SI-MATIC 130W/B programmable controller of Siemens. The PLC has large capacity and can connect 512 input/512 output signals to drive 27A load directly. Siemens 3 system external PLC can be controlled to three, in general, PLCl is used to control the sequential action of machine tools; PLC2 is used to control auxiliary functions, such as displaying PLC alarm information, vacuum hanger operation information, tool library management; PLC3 is used to connect with the upper computer, so Siemens 3 system is very suitable for processing center and soft. Sex manufacturing system is adopted.

- No information

-

1. Design objective of electronic crane scale network management. (1) Adopt advanced distributed data processing techno…

-

Electronic crane scale bearing platform installation to focus Electronic crane scale can be installed generally on the li…