The difference between screw jack and hydraulic jack

Keyword:Screw Jack Time:2019-11-10 20:29:28

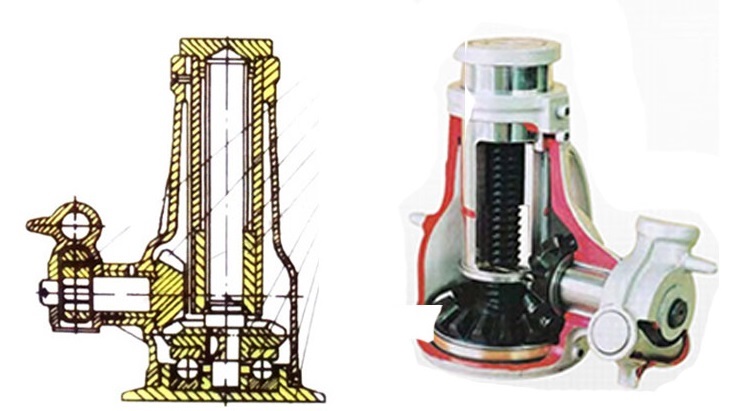

Screw Jack and hydraulic jack are the jacks we often use. What's the difference between screw jack and hydraulic jack? Screw jack is also known as mechanical jack. It uses screw lift to transfer power. Like wrench bolts and nuts, it keeps screwing nuts, and the bolts will stretch out and retract.

Hydraulic Jack uses Pascal principle and hydraulic oil to transfer power. A small piston is pressed by a handle, and the small piston pushes the hydraulic oil to generate pressure. The hydraulic oil passes through the pipeline (invisible in the case) and enters the lower part of the big piston. The pressure of the hydraulic oil acts on the big piston and pushes the big piston upward, thus forming a great thrust (thrust = pressure x area). Keep pressing small piston, big piston will rise slowly. Open the relief valve, the big piston can retract under the action of gravity.

The screw jack is compact in structure, small in size, light in weight and easy to carry. It is widely used in lifting operations of factories, warehouses, bridges, wharfs, transportation and construction engineering departments. Screw jack, also known as mechanical jack, is driven by human through the screw pair, with screw or nut sleeve as lifting parts. ordinary screw jack supports heavy objects by thread self-locking, which is simple in structure, but low in transmission efficiency and slow in return. Specification types of screw jacks are: 3T screw jack, 5T screw jack, 8T screw jack, 10T screw jack, 16T screw jack, 20T screw jack, 25t screw jack, 32T screw jack, 50T screw jack, 50TD screw jack, 100T screw jack, 200T screw jack, 320T screw jack. Rotary jack, 380T screw jack.

Screw jack is a kind of jack used for a long time in all jacks. It has self-locking function and is equipped with brakes. Relax the brake, the weight can drop quickly by itself and shorten the return time. It is widely used in the jack series nowadays. Because of the high stability of screw jack, many people choose screw jack when they need fixed Jack in design and construction. Because the stability and safety of hydraulic jack is not so high, it is not recommended to use in fixed equipment. Generally, products designed in fixed equipment are fixed with fixed screw. Not long-term use, so that the choice is to be more fixed. Jacks are used in many occasions in life, especially in some cars. And many of them are car jacks. Used for assistant, maintenance, maintenance, support and other work. Screw jack is the most commonly used product in all Jack series, because the screw jack fixed in the equipment has higher stability and safety factor. The performance-price ratio is also very high. The lifting weight of screw jack is about 200T. Whether it is a small bridge car, a large truck or construction equipment, these occasions are very suitable for use!

Helical jack, also known as mechanical jack, is one of the commonly used jacks. Now I will sort out the problems that should be paid attention to in the use of helical jack for you.

1. Keep the body surface clean regularly and check the internal structure regularly to make the pinion in rocker flexible and reliable and the lifting sleeve lifting freely.

2. The friction surface between the lifting sleeve and the shell must be oiled at any time, and other oil injection holes should be oiled and lubricated regularly.

3. In order to take into account the safety in use, avoid overloading and working with illness, it is not appropriate to use multiple sets to avoid danger.

- No information

-

1. Design objective of electronic crane scale network management. (1) Adopt advanced distributed data processing techno…

-

Electronic crane scale bearing platform installation to focus Electronic crane scale can be installed generally on the li…