Talking about which is more powerful than the hydraulic jack and the screw jack

Keyword:screw jack Time:2019-11-10 20:31:35

Talking about which is more powerful than the hydraulic jack and the screw jack

Separate hydraulic jack and farewell hydraulic jack, vertical hydraulic jack is a new series of products finalized by the state. It is compact in structure, small in size, light in weight and inconvenient in carrying. It is widely used in lifting work of workshop warehouse, bridge, port, transportation and construction engineering.

Vertical hydraulic jack and can only be established application, its mission ambient temperature is - 20 degrees Celsius to + 45 degrees Celsius, not suitable for acid-base and corrosive gas applications. Automotive jacks, which are inconvenient and portable, are widely used in the lifting work of workshop warehouses, motorcycle, automobile parts, bridges, ports, transportation and construction projects.

The only disadvantage is that the application can only be established, and due to its disadvantage, we have developed and designed a split hydraulic jack, which has electric and manual jacks.

China Hydraulic Jack Action RAMHOIST Hydraulic Jack and Electric RAMHOIST Hydraulic Jack

Manual farewell hydraulic jack features:

1. Equipped with various accessories, it has the functions of lifting, roofing, shoveling and splitting, and it can be installed by speed connector.

2. Apply well, the oil pump can actively unload when overloading.

3. The equipment is lightweight, inconvenient to use and carry.

4. The oil pump adopts compound structure. When no load, the flow is large, the speed is fast, and when heavy load, the flow is small and the speed is slow.

The electric hydraulic jack has the characteristics of large input force, light weight and far clearance operation. With the ultra-low pressure electric oil pump station of our factory, it can finish the work of jacking, pushing, pulling and extrusion in many situations. It is widely used in construction engineering, shipbuilding, metallurgy, mining, petrochemical industry, Railway Engineering and other industries. Jacking, stretching, extrusion, etc. Over the years, it has been widely used in basic settlement test and static pressure pile.

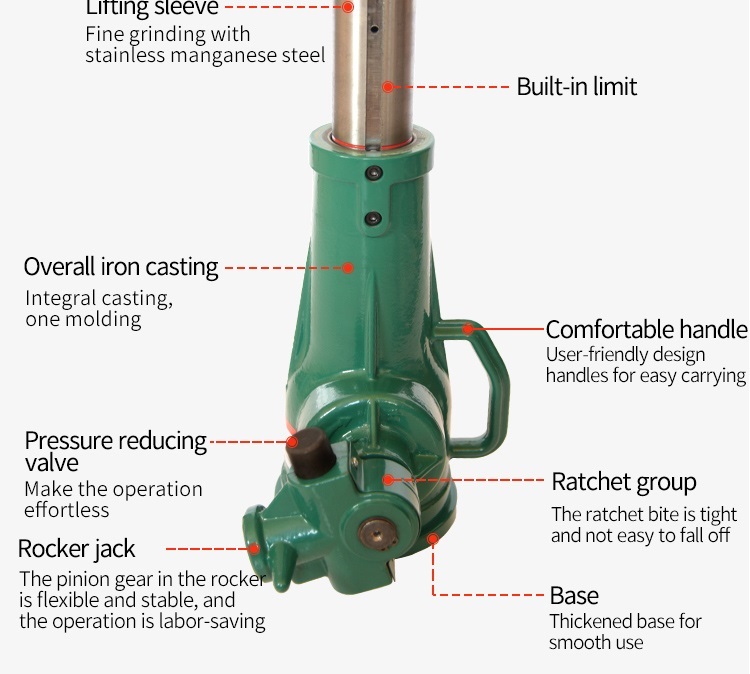

Screw jack is also called mechanical jack, gear jack and rack jack. Screw jack is a new series of products of national stereotyping. It is compact in structure, small in size, light in weight and inconvenient in carrying. It is widely used in lifting work of workshop warehouse, bridge, port, transportation and construction engineering.

Screw jack structure function:

Screw jack is mainly composed of main frame, base, bevel gear pair, screw, nut, landing sleeve, thrust bearing, ratchet set cross arm pull foot and so on. The screw jack is designed with mechanical principle, and it has no oil. The operation is simple and the oil leakage scene will not occur.

The screw jack adopts the mechanical principle, and then pulls the handle back and forth, pulls the claw to advance the ratchet clearance rotation, and the small bevel gear starts the big bevel gear and makes the lifting screw rotate, so that the lifting sleeve can be lifted or lowered, thus reaching the purpose of lifting pulling force.

- No information

-

1. Design objective of electronic crane scale network management. (1) Adopt advanced distributed data processing techno…

-

Electronic crane scale bearing platform installation to focus Electronic crane scale can be installed generally on the li…