Measurement error of electronic bench scale

Keyword:bench scale Time:2019-11-11 10:30:06

Measurement error of electronic bench scale

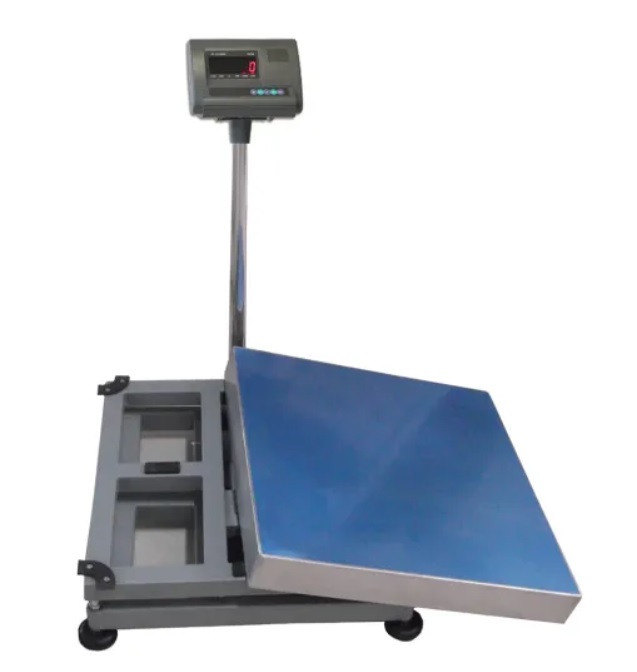

Classification of electronic bench scale in function: display electronic bench scale, logistics electronic bench scale and print electronic bench scale and other products. It is an electronic weighing device composed of independent ground scale body, vertical bar and display, with an independent load weighing platform. However, due to many external reasons, the weight value of the product may be deviated. Next, let's have a look.

1. Error caused by environment: bench scale will be affected by the surrounding environment weight measurement value.

2. The error caused by the bench scale itself: the DC drift value during weighing and the inclined surface presented by the product placement will cause some errors caused by itself.

3. Dynamic product weight measurement error: the general weight measurement is completed in the static state, but for bench scale products and electronic scale is not the same, it is in the dynamic environment of the air directly weighing, so the data will be slow, there will be some error.

This is also a part of the error of the product, and there may be some small errors in the unknown situation, so we should pay attention to the environment, the performance of the product to understand what will happen also need to explore. This is what we need to know when using the electronic weighing machine, and it will help us use it correctly.

The person that often USES electronic bench scale knows electronic bench scale to have a problem actually, it is same article, put on 4 corners follow to put in the middle, weigh the portion that come out is not same, actually this is so-called Angle difference, so is Angle difference normal now resemble? Is there any solution?

Let's take a look:

Among the appraisal items of electronic weighing apparatus, one of them is the appraisal of Angle difference (1/3 maximum weighing). The mutual difference of Angle difference cannot be greater than the identification tolerance (plus or minus 1 D of standard weighing). The performance index of Angle difference directly affects the accuracy of weighing. The electronic bench scale requires the identification of the four Angle difference of the ballast, that is, the weighing plate is evenly divided into four equal parts from the center, and the 1/3 maximum weight standard weights are added respectively, the error of the value should be within the inspection. Platform scales and other scales are used to detect the coupling of several angles (several angles with several sensors).The principle and structure of the weighing sensor used in the electronic bench scale are as follows. Double control parallel beam; Parallel beam with five holes; The structure of a single empty parallel beam.

The higher the accuracy of the sensor, the smaller the Angle difference. Of course, no matter how accurate the sensor is, it will have a certain Angle error. Therefore, it is very important to debug the sensor (file Angle) during installation and debugging. The so-called debugging is to repair the sensitive part of the corresponding blind hole. The closer the display code of the four corners is to the standard code, the higher the accuracy of the electronic bench scale will be.

- No information

-

1. Design objective of electronic crane scale network management. (1) Adopt advanced distributed data processing techno…

-

Electronic crane scale bearing platform installation to focus Electronic crane scale can be installed generally on the li…