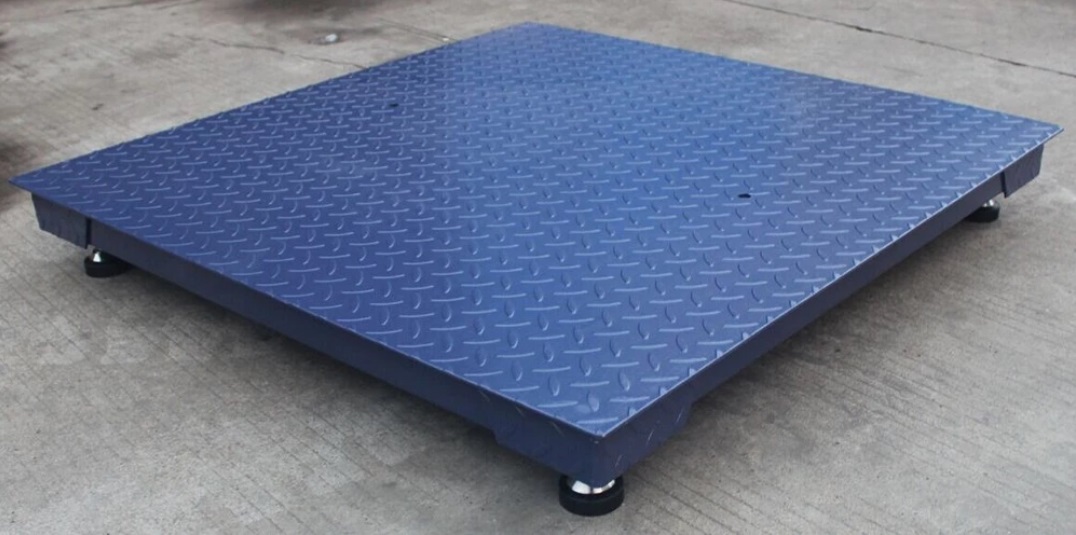

How to install a floor scale?(1)

Keyword:floor scale Time:2019-11-11 16:58:34

How to install a floor scale?(1)

1. Preparation before installation

The preparation work before installation will test the facilities and clean the related areas, so the preparation work includes the following contents:

(1) check the position size, levelness and relative elevation of each supporting plate of the weighing sensor. Whether the position of limit roof at both ends of the floor scale table is correct.

(2) threading tube and connection point. To ensure the connection effect of the threading tube, in addition, it is necessary to ensure that the resistance at the junction meets the relevant requirements.

(3) foundation pit environment. It is necessary to conduct an in-depth study and investigation on the drainage capacity of the foundation pit. At the same time, it is necessary to thoroughly clean up the sundries in the foundation pit.

2. The floor scale platform is in place

The work of this process includes the following:

(1) sensor aspect. Due to the high precision of the sensor, the sensor cannot touch the ground during the installation process.

(2) lifting process of cap. For single weighing platform, the lifting can be carried out according to relevant standards. For multi-unit weighing platform, the lifting and installation should be carried out completely according to the label of weighing platform. At the same time, the connection of different weighing platforms should be paid attention to.

(3) after the floor scale platform is placed in the foundation pit, place the limit substrate on the cast iron bottom plate.

3. Install connectors

In said body installation process, involving a large number of fittings installed, in rust, need for fitting butter, another in the process of the installation of fittings, need to remove the scenes of the wood, concrete methods using jack bearing units, after the removal of the wood will say down, in the process, to ensure that the supporting columns can free activities. After the balance body is put down, the level should be used to detect the levelness and correct the gap. When the levelness is insufficient, the steel plate should be used for adjustment. It should be noted that, for multiple weighing platform floor scale, the best plan is to let the overall fall of weighing platform, in order to ensure the levelness of weighing platform.

4. Install limit bolts and adjust limit clearance

During the installation of the system, the clearance between the limit bolt and the sensor should be maintained at 2~3mm. Only on this basis can the bolt be tightened. When the clearance fails to meet the relevant requirements, the system should be adjusted again.

For truck floor scale, bridge type sensor in place when the available equipment, including jack jacking weighing platform, mobile sensors, on steel ball on the arc grooves rolling a little movement in place, after put in place to check each fulcrum for impending phenomenon, if any should be appropriately under the sensor mat thickness of steel plate, to ensure that each fulcrum uniform stress. Then adjust the four limits at the two ends of the floor scale, generally the gap is controlled at about 0.5cm, the limit bolt should be coated with butter for future maintenance and adjustment.

- No information

-

1. Design objective of electronic crane scale network management. (1) Adopt advanced distributed data processing techno…

-

Electronic crane scale bearing platform installation to focus Electronic crane scale can be installed generally on the li…