Principle and application of floor scale sensor

Keyword:floor scale Time:2019-11-12 9:22:34

Principle and application of floor scale sensor

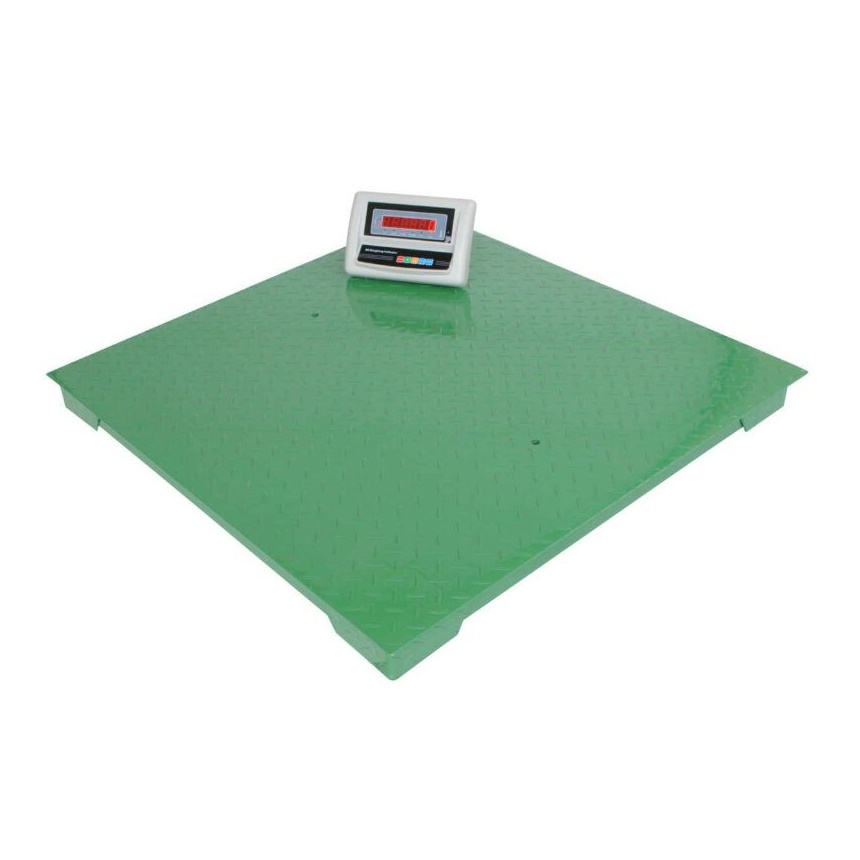

1. Structure and working principle of electronic floor scale sensor

Electronic vehicle sensor is mainly composed of weighing display, weighing sensor, junction box, carrier, connecting parts and other parts, and equipped with computer, voltage control power supply, printer and other external equipment. Working principle of electronic floor scale, is measured by using substation principle of non-electricity gravity into electricity which is weighed, it is mainly composed of digital conversion module (A/D) and the simulation of weighing sensor in two parts, with microelectronics technology and microcomputer technology, adjust the partial load can be automatically or manually, can automatically modify sensor number, can automatically to addressing the single sensor and read the data.

There is a strain bridge below the elastomer of the weighing sensor. The weighing sensor is installed below each weighing point of the weighing platform, and the corresponding cables are parallel in the junction box. When said of automobile electronic floor scale, weighing sensor will receive said Taiwan by force, and through the strain bridge electrical signal to output, and then the output signals after linear amplification is passed to A/D converter, then which converts analog signals into digital signals, digital signals to the microcomputer processor, again after dealing with the microcomputer processor, the display window shows according to quantity, in the end, by computers and printers will be said of the vehicle quantity, gross weight, net weight and tare weight number) is stored in the computer, can through the computer statistical these data management and report print.

2. Choice of electronic floor scale sensor

Through the above analysis, it can be seen that electronic floor scale is a weighing device that converts non-electric charge into electric charge by using the principle of force-electricity conversion. To realize the conversion from force to electricity, the most critical equipment is the sensor. Therefore, the choice of weighing sensor is very important in practical application. Usually prescribed static, electronic floor scale sensor maximum load = sensor number * 70% rated load sensor, due to the dynamic process of vehicle said will be influenced by factors such as shock, vibration, and said the body's own self-respect, part of the sensor in the car said moment is 10% ~ 40% more than the actual load of weight, sometimes there will be more than the rated load condition, the vehicle when the accuracy of weighing down.

In order to ensure that the sensor does not exceed its rated load when working, the 70% coefficient is stipulated to improve the accuracy of weighing. Of course, the relevant technical parameters, especially the sensitivity, should also be considered in the actual selection.

Take qs-30t-a weighing sensor and xk3190-d9 meter as examples to analyze the sensitivity. The sensitivity of QS is 2.0m V/V, and the output excitation voltage of D9 is 8V. In the case of rated load, the sensitivity of the weighing sensor is the ratio between the maximum output signal of the sensor and the excitation voltage, i.e. MV /V. Then, when the load is 30t, the analog output signal of the weighing sensor 2m V/V×8V=1.6m V. When multiple sensors are used, in order to determine whether the selection of sensors is reasonable and correct, it can be determined according to the calculation formula U=S×V×O/C×R. S stands for measuring range (kg); O represents the excitation voltage (V); C stands for range (kg); R represents the number of sensors, which is the number of parallel voltage circuits in the junction box. Only when the input sensitivity of the meter is less than U is considered qualified.

- No information

-

1. Design objective of electronic crane scale network management. (1) Adopt advanced distributed data processing techno…

-

Electronic crane scale bearing platform installation to focus Electronic crane scale can be installed generally on the li…