Error analysis of electronic floor scale verification

Keyword:floor scale Time:2019-11-12 9:49:36

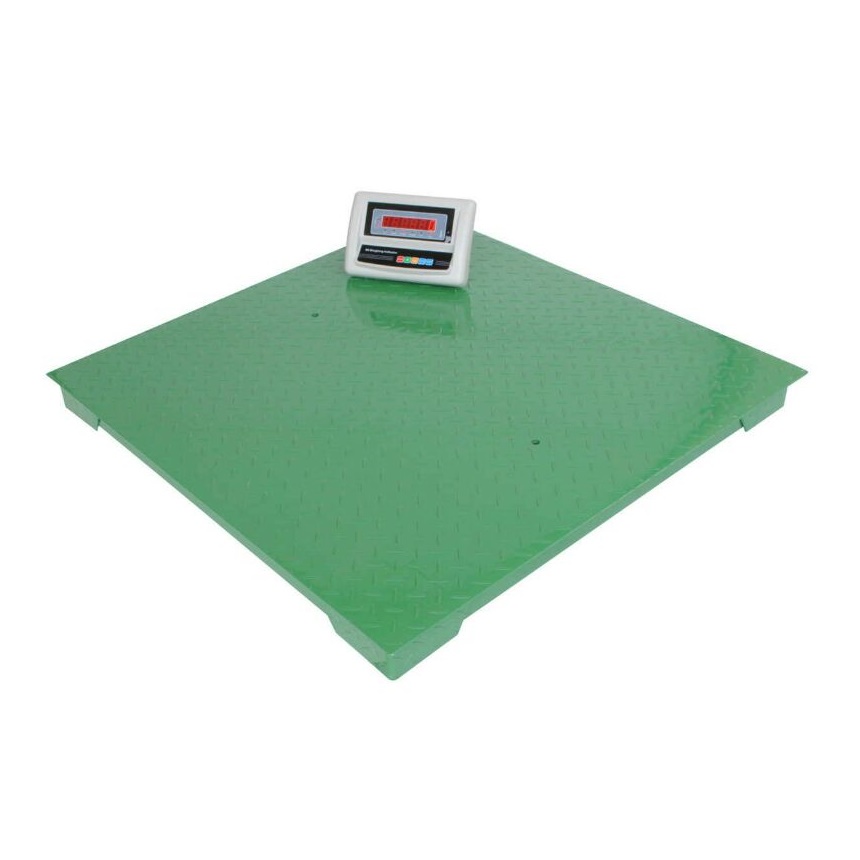

Error analysis of electronic floor scale verification

There are always errors in the verification process of electronic floor scale, and there are many factors causing errors. The reasons for the errors are as follows:

(1) Error caused by verification environment. Electronic floor scale has a strong sensitivity to temperature and other environmental factors. Under normal circumstances, the installation of electronic floor scale is carried out outdoors, and the outdoor environment is not easy to control. Temperature, wind power and other environments will have a great impact on the electronic floor scale. For example, the temperature should be controlled within a certain range. If the temperature is too high or too low, the floor scale will fail, resulting in a large error and loss of its use significance. The wind also has an important influence on the verification of electronic floor scales. The unsteady airflow generates pressure on the symmetrical platform, which increases the external force of the sensor and affects the weighing result.

(2) Error caused by standard weight. Standard weights should be set according to relevant specifications, and their error should not exceed the measurement requirements of JJG99. However, standard weights are easy to be corroded in the long-term use, resulting in inaccurate quality. In order to avoid errors caused by standard weights, it is necessary to check them regularly.

(3) Errors caused by verification methods. To verification method are many, electronic floor scale method will lead to different error, verification methods usually include: substitution method, sometimes related department to Jordan farmar quantity is not enough, will use a stone or sand instead of Jordan farmar is weighed, this method is more haste, without fully considering the characteristics of the electronic floor scale weight, and whether the alternatives to ensure measurement accuracy, is bound to cause the error in the process of Jordan farmar alternative. The replacement of weights should follow certain principles. The repeatability of weights should be considered and the maximum weight of standard weights should be set. Check truck method, this method is easy to be affected by fuel oil, refueling or fuel consumption makes it in constant change, poor stability, the check truck to carry out a certain transformation, control the position of the tank, real-time monitoring of fuel consumption, the error calculation into the verification results of the error, in order to reduce its impact.

(4) Errors caused by metrological verification personnel. Due to the different technical level and working attitude of the verification personnel, there will be great differences in the verification results of the same electronic floor scale. Therefore, it is necessary to train the verification personnel, strictly regulate the operation procedures and standards, improve the quality of the verification personnel, so as to ensure the accuracy of the verification results. The verifier should observe the gap between the position of the electronic floor scale and the sensor before the test, as well as the firmness of various devices. At the same time, it is necessary to control the addition of weights, read the weight with accuracy, and check the verification results to reduce the working error.

(5) Full preheating and preloading of electronic floor scale. Preheating can ensure the stability of the work of the electronic floor scale. Preheating time is an important factor. The function of preloading is to reduce the gap.

(6) Error caused by verification of biased load. The deviation of partial load makes it far away from the central area and causes different size errors in all directions. The deviation is also related to distance. The larger the distance is, the bigger the error will be and the faster the growth speed will be.

- No information

-

1. Design objective of electronic crane scale network management. (1) Adopt advanced distributed data processing techno…

-

Electronic crane scale bearing platform installation to focus Electronic crane scale can be installed generally on the li…