Principle and development of dynamic floor scale

Keyword:floor scale Time:2019-11-12 9:50:29

Principle and development of dynamic floor scale

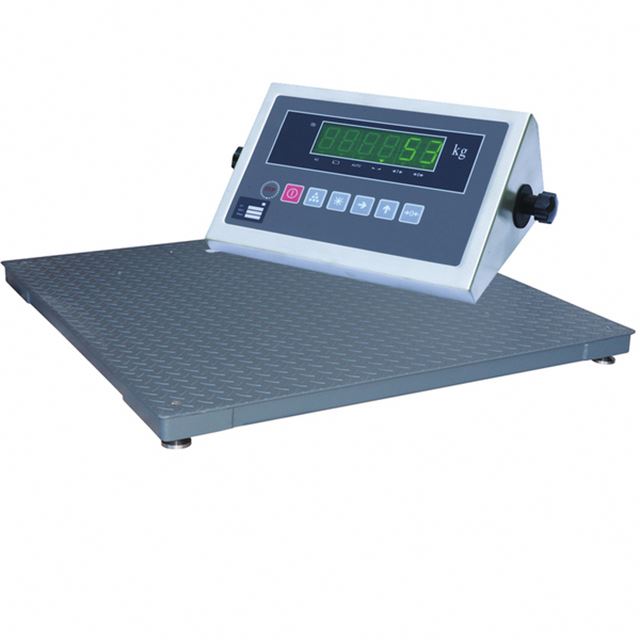

1. The structure of dynamic floor scale

Dynamic floor scale general carrier, pressure sensor, signal processing box, electrical control box, grating identification system, number line trigger and display device. Weigh-in-motion bearing apparatus should be with the road Toll Gate in a plane, when load vehicles through the bearing is triggered when the pressure sensor, pressure sensor, pressure value into a voltage signal, voltage signal through the filter, big hair treatment will be sent to the box, the processed signal into weighing numerical transmitted to the display, to read the weight. The number line trigger is the total number of vehicle axles measured in the process of vehicle passage. All kinds of data are integrated and processed by increasing the tariff coefficient, and the total amount of charges and other information are displayed in the toll booth.

2. Principle of dynamic floor scale system

Load vehicles through weighing apparatus, raster detect vehicles entered the weighing, vehicles in turn by each shaft bearing, triggering sensor elastic device in the axle load and proportional changes in the elastic range of the corresponding signal, this signal through A filter to exclude other interfering signal first, after the amplifier amplification and A/D converter convert analog signal to digital signal, digital signal sent to the processor of each axis superposition and processing, so as to get the vehicle's weight in the display instrument.

3. Classification of dynamic floor scales

3.1 axle load dynamic floor scale

The most common type of dynamic floor scale is the axle load dynamic floor scale. The axle load dynamic floor scale has a simple structure, which is composed of four strain sensors of the base bearing and the supporting bearing. When each axle of the dynamic vehicle passes on the load-bearing device successively, the axle load of the vehicle is transformed into the pressure corresponding to the strain sensor, which converts the pressure into electrical signals for processing to obtain the weight of each axle of the dynamic vehicle. The grating sensor will identify the final work of the vehicle entering and leaving the weighing area, so as to calculate the total weight of the vehicle. The accuracy of weighing depends on the road infrastructure, vehicle speed, vehicle mode and signal processing capacity. The advantages of dynamic floor scale are small area, fast construction speed, easy installation and low cost. The disadvantages are as follows: because the load carrier is too short, the effective area of weighing is small, resulting in poor weighing repeatability and low reliability. The way of vehicle driving has a great influence on the weighing.

3.2 wheel weight dynamic floor scale

Wheel weight dynamic floor scale is also known as bending plate dynamic floor scale, just as its name implies, wheel weight dynamic floor scale is composed of bending plate frame, which itself ACTS as a pressure sensor. When the vehicle tire passes through, the bending plate is subjected to the pressure of the tire and the corresponding resistance changes. The change in resistance causes the voltage and pressure difference to be transferred to the processor for processing so as to calculate the weight of the wheel. The advantages are small amount of road infrastructure, fast construction progress and low cost. The disadvantage is that the effective area of weighing is small, which leads to low reliability and higher requirements on the external environment.

3.3 full-vehicle dynamic floor scale

The two floor scales have strict requirements on road infrastructure and vehicle driving mode, so the full-vehicle dynamic floor scales enter the market. The whole vehicle dynamic floor scale has a long weighing area in the driving direction, and the load vehicle can be parked on the load carrier. The whole vehicle dynamic floor scale is composed of multiple pressure sensors, with an accuracy of 0.5 or even 0.2. The running mode of the vehicle has almost no influence on the scale, which prevents the bad phenomena of jumping scale, twisting scale and punching scale in order to reduce the scale. Its disadvantage is large area of road infrastructure, complex installation, high cost

- No information

-

1. Design objective of electronic crane scale network management. (1) Adopt advanced distributed data processing techno…

-

Electronic crane scale bearing platform installation to focus Electronic crane scale can be installed generally on the li…