Introduction to weighing system of floor scale

Keyword:floor scale Time:2019-11-12 9:51:27

Introduction to weighing system of floor scale

The weighing system integrates new and high technologies such as weighing, detection and control, which can effectively address the disadvantages in the management process of weighing and weighing, and achieve the prevention of cheating, automatic weighing and monitoring process. Intelligent electronic weighing system is based on computer technology, microelectronic control technology, weighing technology in one, weighing automatic data collection, computer electronic monitoring management technology and other organic combination of high-tech products. We can provide customers with a complete intelligent weighing monitoring solution, provide a number of high-tech integration, complete set, intelligent electronic weighing system.

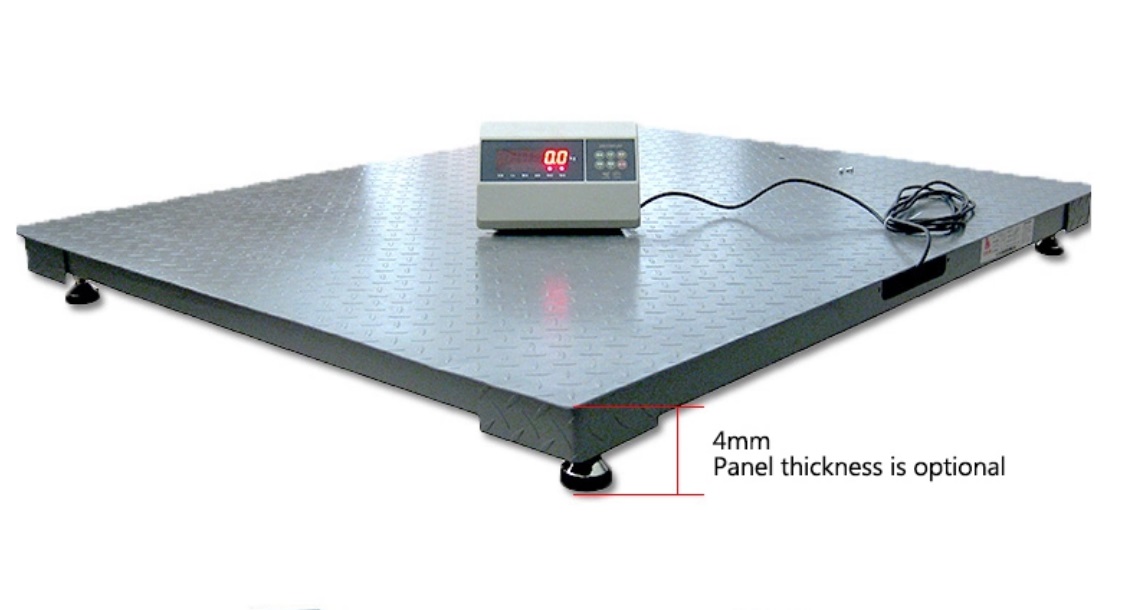

Intelligent electronic floor scale system is composed of floor scale, large screen, infrared vehicle separator screen (point or strip light screen), camera monitoring system, computer control and management system. Each system work independently, through the computer system will be a number of systems organic combination, centralized control, the realization of automatic identification of vehicles, weighing and weighing data storage, management, to meet the customer's modern, efficient weighing management needs.

Key options for automatic weighing:

1 Non-contact IC card identification system: automatic entry of car number information, reduce or do not need to manually enter weighing information.

2 Camera monitoring: monitor the license plate, the parking position of the car, the materials on the car, the loading and unloading of personnel, etc.

3 Gate, ground sensing vehicle detection system: as a barrier allowing weighing, to ensure the weighing rhythm of the vehicle.

4 Voice prompt: if not in place, it will prompt the vehicle to move; Weighing end to give the conclusion.

Infrared vehicle separator (dot type or strip type): automatic detection and identification of whether the vehicle is on the scale.

Electronic scale is mainly composed of bearing device, weighing display instrument (hereinafter referred to as the meter), weighing sensor (hereinafter referred to as the sensor), connecting parts, limit device and junction box, etc. It can also be equipped with external equipment such as printer, large display screen, computer, weighing management software and stabilized voltage power supply. Loadometer connected to the computer, printed pound list, is a new way of management; The weighing management system is composed of computer, printer, instrument and weighing software. Vehicle divided into two pounds, gross weight minus tare weight to get a net weight printed pounds list;

The electronic floor scale USES the principle of strain measurement to weigh. A strain gauge is attached to the elastomer of the weighing sensor to form the wheatstone bridge. When there is no load, the bridge is in equilibrium and the output is zero. When the elastomer is under load, each strain gauge then generates strain proportional to the load, and the external load can be measured by the output voltage.

The working principle of

Are weighing or truck in supporting table, under the influence of gravity, through the load transfer of gravity to the weighing sensor, weighing sensor elastomer deforms, attached with the elastomer strain gauge bridge on the road out of balance, output directly proportional with the weight value of electrical signals, the linear amplifier will signal amplification, and then converted to A digital signal by A/D, by instrument microprocessor (CPU) after the weight signal processing according to the weight data directly. After the printer is configured, the weighing data can be printed and recorded. If the computer and weighing management software are configured, the weighing data can be comprehensively managed through the weighing management system.

- No information

-

1. Design objective of electronic crane scale network management. (1) Adopt advanced distributed data processing techno…

-

Electronic crane scale bearing platform installation to focus Electronic crane scale can be installed generally on the li…