Brief discussion on electronic floor scale maintenance

Keyword:electronic floor scale Time:2019-11-12 10:09:16

This paper briefly introduces the working principle and classification of electronic floor scales based on verification and repair experience, and expounds the cheating problem of electronic floor scales, especially discusses the common faults and repair methods of electronic floor scales.

Electronic scale has high accuracy, simple and convenient operation, modular structure, easy installation and strong applicability. Therefore, electronic scale has become the main quality measurement equipment. Due to the large area of electronic weighing, frequent use, the occurrence of fault is inevitable. In the late 1980s, the author began to engage in the repair and verification of weighing apparatus and experienced the development process from mechanical weighing apparatus to electronic weighing apparatus. Following through the summary of experience, refer to the maintenance notes, a brief description of the electronic floor scale common failures and repair methods.

1. Composition and design principle of electronic floor scale

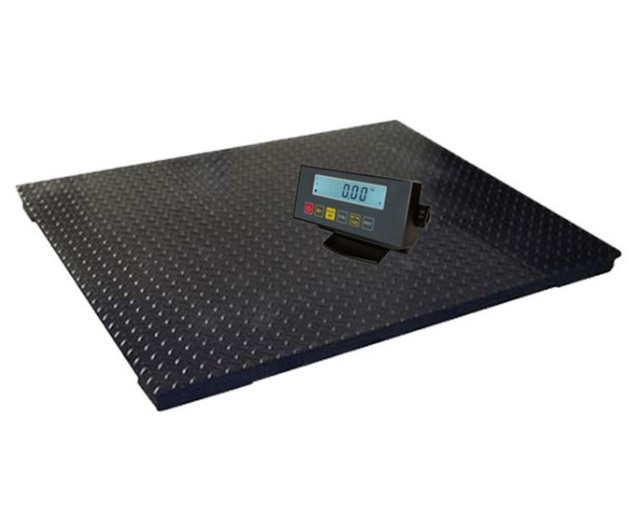

Electronic floor scale is composed of scale body, sensor, branch box and display instrument. According to the measuring range can be divided into desktop scale, platform scale, floor scale, electronic truck scale, sometimes also according to the use, industry, location classification.

When a certain quality of objects in the electronic scales on the body, produced by the gravitation of gravity through the transmission system to a pressure sensor, pressure sensor geometry deformation occurs, through the piezoelectric effect, make the pressure sensor output impedance value produces change, cause a corresponding change of the excitation voltage at the same time, we according to the change of sensor output signal for analog signals. The analog signal is filtered, amplified and A/D converted into digital signal. The digital signal is transmitted to the central processing unit (CPU), which controls the interface circuit and program according to the key input instruction through calculation and processing, and outputs the weighing result digitized to the display and printout port.

2. Cause analysis of electronic floor scale failure.

The failure of electronic floor scale can be classified into three aspects, namely, mechanical reason, electronic circuit reason and external environment reason.

First, consider the external environment. Including power supply voltage, power supply frequency, mechanical vibration, wind, lightning and electromagnetic field interference and other factors make the output value of electronic floor scale change, resulting in error or even damage. We only need to meet the use conditions of electronic truck scale, except force majeure.

The second is the change and damage caused by the mechanical cause of the value error or even serious failure. This includes the geometric deformation of the scale body, the looseness or even damage of the geometric position of the mechanical limit device, the blockage of the clearance of the scale body by foreign bodies, the change of the levelness of the foundation, etc. It is easy to deal with the abnormal limit device, foreign matter blocking the scale body and the uneven foundation. The deformation of the scale body can be disassembled, leveled, reinforced and re-welded. Pay attention to the prestres during welding.

The third is the fault caused by electronic circuit. For example, the junction box shielding is poor or short circuit, pressure sensor damage or linear error, weighing display instrument circuit fault or interface mismatch, signal cable impedance is too large and poor contact, etc.

- No information

-

1. Design objective of electronic crane scale network management. (1) Adopt advanced distributed data processing techno…

-

Electronic crane scale bearing platform installation to focus Electronic crane scale can be installed generally on the li…