Analyze the special fault of electronic floor scale

Keyword:electronic floor scale Time:2019-11-12 10:12:53

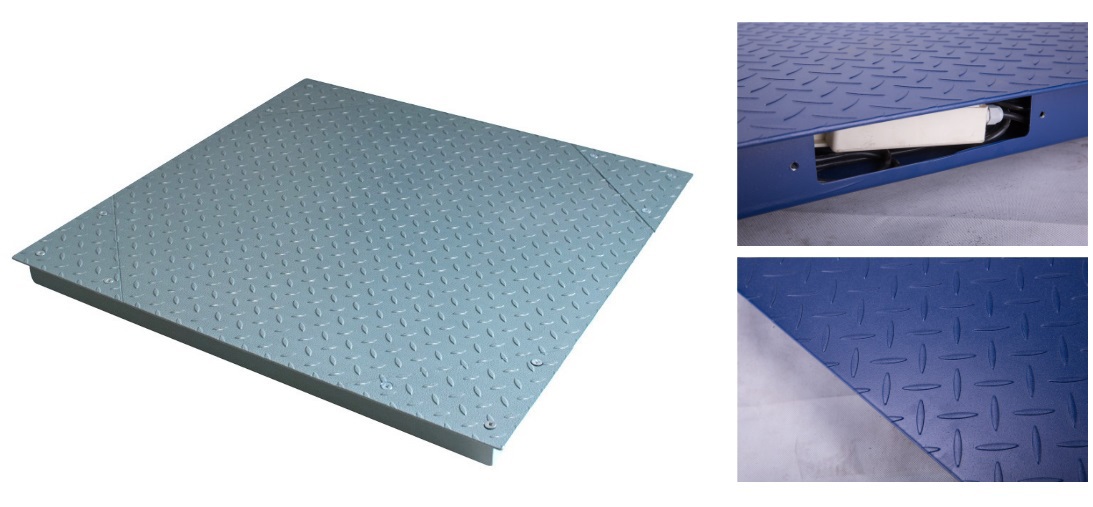

With the rapid development of science and technology, electronic floor scale occupies an important position in production and management. In order to give full play to their functions, their reliability and accuracy of measurement must be guaranteed. However, both the newly installed electronic floor scales and the electronic floor scales that have been used for many years will have some faults, resulting in their normal use.

1. Overview

The fault of electronic scale can be divided into two types: common fault and special fault. But no matter what type of fault, is nothing more than a weighing display, weighing sensor, power supply, connection lines and mechanical transmission mechanism produced by several major aspects. The cause of its failure is caused by improper installation design or improper use and natural damage. The following are some of the more specific troubleshooting experiences we have had in the installation and maintenance of electronic floor scales.

2. Congenital deficiency of electronic weighing components

Electronic floor scale is one of the most widely used electronic floor scales. However, an unprecedented phenomenon occurred during the installation and debugging of an electronic floor scale in a rolling mill. That is, when calibrating with the test weight after installation, it is found that the weight displayed by the display instrument does not change according to the weight applied, but varies from more to less. Moreover, the number displayed by the meter is also related to the position of the weight, so it cannot be calibrated normally.

The connection mode of the weighing sensor of the electronic scale is connected in parallel. After careful inspection, the connection line of the sensor is correct (the sensor is connected according to the wiring diagram of the manual in color). The display instruments and mechanical parts are also without any fault. After careful analysis of the above phenomenon, we thought the problem still appeared on the sensor. In order to further find out the reason, we first calibrated the display instrument with the simulator and then connected it into the sensor, and then weighed the four corners of the scale with a weight. The results showed that the three corners were positive and the other one was negative. Therefore, we conclude that the internal wiring of the sensor at this Angle is wrong.

After switching the positive and negative leads of the bridge pressure or signal line of the sensor, the Angle also shows a positive value. Because the positive and negative poles of the internal leads of the bridge pressure or signal were connected in reverse when the sensor was packaged before the factory, the above faults occurred when the sensor was connected according to the normal color code during installation. After changing the connection, the sensor was re-calibrated and the above phenomena were eliminated.

Another example is disconnection of the display instrument. The multimeter was used to check the bus, and it was found that the signal positive pole was connected to the ground wire. Therefore, when the sensor bus was connected to the display instrument system, a short circuit between the signal positive pole and the bridge voltage negative pole was caused, which destroyed the normal working state of the bridge road of the sensor. Next, all the disconnected sensors were checked separately and the results were normal. Undoubtedly, the problem appeared in the junction box of the sensor. When the multimeter is used to check the junction box of the sensor separately, find out the short circuit between the ground terminal of the junction box and the signal positive terminal of the sensor in the junction box. Look carefully and find out where the printed circuit on the printed circuit board in the junction box has a short circuit. The problem is caused by the product quality of the junction box. (after analysis, the junction box has not been carefully inspected before delivery, otherwise the above problems should not appear). After the short circuit is cut open with the blade, the above fault is eliminated.

- No information

-

1. Design objective of electronic crane scale network management. (1) Adopt advanced distributed data processing techno…

-

Electronic crane scale bearing platform installation to focus Electronic crane scale can be installed generally on the li…