Answer for RM Electric Chain Hoists

Keyword:RM Electric Chain Hoists, Electric Chain Hoists Time:2018-11-26 21:58:15

Tips after receiving electric chain hoist:

① The bottom hook does not swivel

Molding powder is a little thick and tighten, pls swivel for some times and could be rotated, since there is no grease in the bearing (not greased prior to shipping).

② Squeaking on motion sometimes

Side rollers do not have bearing and are not lubed, It would be nice for to spray with a dry lithium lube or something that will not drip, and it will not squeak.

③ The hoist breaks do not fully open and they are not stuck

Find a copper stick, remove the plastic cover of motor, beat motor shaft for 2-3 times.

Problem: usage time is long.

④ Operated the hoist with out any load and it worked correctly for up and down motion, But it tested with load and the hoist could not hold the load or pass the load test.

Move the limit switch up and down for several times, and operate the hoist again.

Problem: limit switch is blocked.

Normally, if one request dual speed hoist, it refers only lifting speed is dual but traversing speed always single. Pls specify if the traversing speed you also need dual speed.

For air transportaion:

Magnetic inspection is must for airfreight (it has relation with motor, if no motor then it does not need), both hoist and electric trolley need inspection since motor is somewhat magnetic.

Pls add ISO46 refrigerating machine oil (gearbox oil) into the grear box, since the oil is poured out due to air transport restriction. gear box is only in hoist but not in motorized trolley or manual trolley, if it is only electric trolley or manual trolley then do not need add any oil at all.

For Dual voltage (reconnectable 230/460), the voltage are reconnectable for either 230 volts or 460 volts.

Our normal default voltage for delivery is 460V(the hoist came wired 460v and customer could rewire to 230v)

For 0.3t and 0.5t

If you use many hours a day, It’s better to use 0.5T since it is more reliable.

For those customers they do not need chain, we suggest you use Japanese FEC80 chain or Chinese grade 80 chain in your side after cargo reaches, eitherwise, I am afraid your chain does not match with our chain wheel

If the hoist doesn’t work after arriving to your side, Pls check the power lines are connected according to instruction, if still failed to work according to instruction connection, then exchange random 2 power lines from 3 power line.

For air transport: Pls add ISO46 refrigerating machine oil since the oil is poured out due to air transport restriction.

We can make the current less than 4amps under 240V 60hz (maximum amp draw at 240V = 4), by using 6 pole motor instead of 4 pole, and change the coiling of 6 pole motor.

For hoist with electric trolley, different contactor is used in hoist and electric trolley.

Very few cases for the damage of motor and contactor for electric trolley.

The main reason is as below:

1, The distance from each wheel to I beam is less than 2mm, for both sides wheels. It is too close to I beam.

2, the I beam is old or not even

Both above principal is same, wheel to beam is too close and wheel can not move and load become big and burn out.

Need see detailed photos for burning part that we will analyse the actual reason

TIPS: Probably motor and contactor are not broken at all, pls use universal electric meter or ohmmeter to measure the electric resistance (ohm) for the six wires from motor, and measure the electric resistance for the six wires from other normal motors, if the results are different, pls examine the distance from each wheel to I beam as It is told above, each wheel to I beam should more than 2mm, in other words, the perfect distance for both wheels is 4-5mm, and examine whether the I beam is old or not even, 2nd, examine whether the wire is loose.

If the motor is broken, it should have some black burning place, then take photos and send.

Contactor goes in bud no hoist motion? Any ideas? (or I have connected the power supply to your hoist, it can't work.)

If this hoist is newly used, exchange random 2 power lines from 3 power line.

If this hoist is used for some time, pls measure the motor and revert the result.

We are trying to turn on the electric hoist but without success. Is there some special procedure to start the tool? Do you think that hoist doesn’t turn on if the ground wire were not installed?

There are 3 power lines in inverse phase sequence protecting device, exchange random 2 power lines from 3 power line.

No special procedure to start the tools and it has no relation with the ground wire installed.

If the engine (motor) burnt, we need to check there is 1 motor or 2 motor in the hoist? For the two motors in the hoist, need to check 1 burnt or total two burnt

For 1 burnt engineer, we need replace motor stator assemable (includes stator, copper coil, motor cover).

For 0.5T dual speed electric chain hoist (without electric trolley), it has 3 contactors, only single speed has two contactors.

For dual speed electric chain hoist, two speed must be switched separately and use normally, and mostly the high speed use is more than low speed, Pls do not connect to one speed especially low speed and use always, in this case, the hoists will be easily broken and life will be reduced, if you only use one speed, pls select our single speed rather than dual speed.

For dual speed electric chain hoist, There are two kinds of push button for controlling two speeds:

1: two points, 1 point is for up (default is slow speed, mean press first, it is low speed, then press again, it is high speed, then third time, it is low speed, fourth time, it is high speed, circulating like this), 1 point is for down (principle is same as up)

2: four points, 2 points are for up (1 point is for slow speed up, 1 point is for high speed up, you can choose whatever you want), 2 points are for down(principle is same as 2 points down)

Two points VS Four points

If you want to change 220V motor to 380V motor in the hoist

Pls take photos of inverse phase sequence protecting device for these 220V 3 phase, we need to check whether this inverse phase sequence protecting device can suit for 380V 3 phase motor, if not we need to supply sutiable inverse phase sequence protecting device.

Only take out the four screws and put in our stator assembly, and change the transformer, then it is finished.

Stator assembly

It is two different things for continuous working time and ED percent (Duty cycle)--ratio of motor ON-to-OFF time

It is exactly 60% ED for three phase single speed hoist, 60% time is for lift and lower, 40% time is stop for 1 cycle.

Normally continuous working time is 40-45 mins for 3 phase, no factory will use hoist to lift goods for totally 40-45min, it is not actual, for 1 phase, the Max. we can make is to work for 30mins, also almost no factory will use 30 mins to lift goods.

For normal indoor use, IP 54 is OK.

For outdoor use, Protection class will be higher(IP55)

If protection class required is more than IP55, then it is Explosion-proof

For IPXX, first X means against outside (solid) material coming in cover (6 is the highest—anti dust), second X means against outside water coming in cover (8 is the highest), it has no relation with EX (Explosion-proof), just EX is normally IP65.

If I need electric chain hoist with IP66 and with stainless steel chain that used in margin environment, is it possible?

Answer: IP 66 is unavailable, we suggest you use normal IP54 with a cover on against water, few water does not affect its usage, for stainless steel chain, we need to import from japan and it needs lots of time and suggest you use zinc plated chain to instead.

VFD (Variable-frequency Drive)

Transformer

Metal chain container and turn hook

For company in Zhejiang, Metal chain container is only available for level 1 (Japanese FEC80 chain), for level 2 (Chinese grade80 chain) normal bulk or oilcloth (tarpaulin), extra cost required for adding metal chain container for level 2.

For company in shanghai, Metal chain container is available for both level1 and level2, but normally fit for chain exceeding 20m, Canvas bag is mostly used below 20m.

Metal (material: iron) chain container’s paint is same as hoists.

How to install metal chain container?

Procedure is same as installing Canvas bag, just screw on two bolts.

For upper hook it is fixed, for bottom hook it is turn hook.

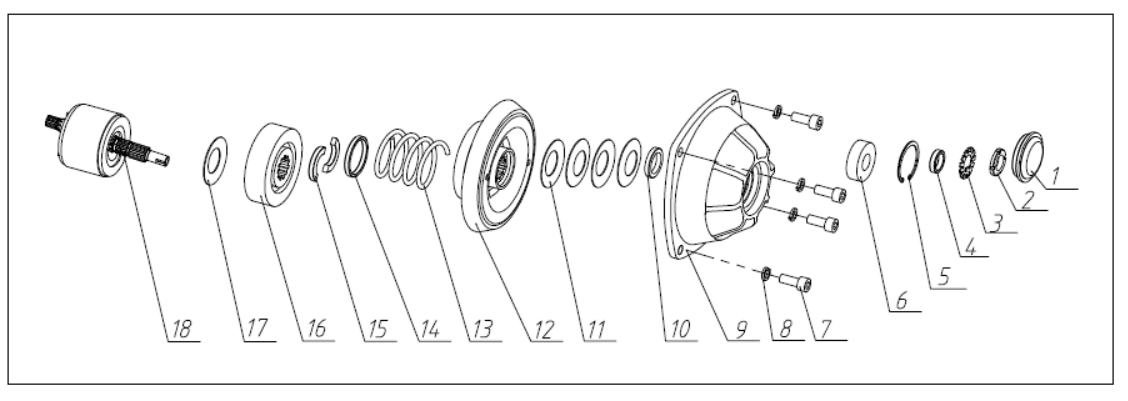

Brake adjusting procedures

Assemble parts 18-2 according to brake diagram step by step.

Adjust part 2-nut, pls note the space between part 16 and part 12, control the distance: 0.5-0.8mm, by measuring with feeler guage.

Align one of part 3 outer gear with part 2 slot and pull up.

put part-1 - plastic cover on.

The hoist I ordered is dual speed 8.2/2.8m/min, why it appears 8.1/2.7 m/min on the nameplate?

±10% tolerance is allowable for the speed according to Rules, the speed is measured by actual conditions.

- No information

-

1. Design objective of electronic crane scale network management. (1) Adopt advanced distributed data processing techno…

-

Electronic crane scale bearing platform installation to focus Electronic crane scale can be installed generally on the li…