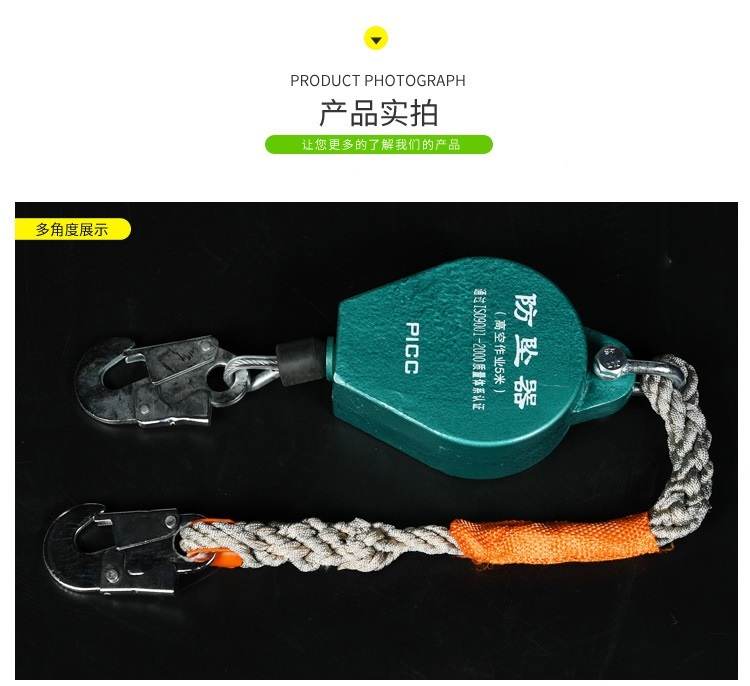

Steel Swivel Hook Wire Cable 20m Retractable Lifeline Fall Arresters

Keyword:Fall arrester Time:2019-11-8 19:18:12

Safety Testing of Fall arrester

When the crane fall arrester is in normal use, the safety rope will expand freely with the human body.Under the action of the mechanism in the device, the operator is in a semi-tense state, which makes the operator feel free of concern. In case of a fall, the pull-out speed of the safety rope is obviously accelerated, and the lock system in the device is automatically locked.The safety rope is pulled out at a distance not exceeding 0.2 meters and the impact force is less than 2949N, which does no harm to the missing person. Load relief means automatic resumption of work. After work, the safety rope will be automatically recovered into the device for easy carrying. However, it is still necessary to be vigilant that the safety fall-proof device is a protective device to prevent the falling of the lifting container when the wire rope or connecting device breaks, so as to protect the life safety of the ground operators and the damage of the lifted workpiece objects.

Safety test method for industrial fall arrester After the fall arrester has been installed according to the instructions, it is necessary to test the fall arrester to ensure its safety. So how to carry out the detection work of the fall arrester?

First, Pre-preparation

1. Cut off the main power supply, switch the electrical box to the state of "installation and maintenance", install the cable used in the test, and then simulate the test according to the working state of the fall arrester at high altitude;

2. Connect the cable used in the test to the connection base marked "Fall-proof Test" in the electric box of the suspension cage, and fix it near the electric box of the suspension cage.

3. Put the torsion disc and cable into the ground station by proper method. After these works are finished, we can do the safety test of the fall arrester.

Second, the beginning of detection

1. Industrial heavy-duty fall arrester (fall arrester evolved into different load-bearing tonnage and different wire rope length product types due to different use environment, according to its actual difference large tonnage fall arrester is called industrial heavy-duty fall arrester, long wire rope is called high-altitude operation fall arrester, the internal structure form of the above product types is the same). The suspension cage is loaded to the highest load, then the main switch is closed, the test cable is pressed and the "up" button on the torsion box is pressed to drive the suspension cage to rise to 10 meters above the ground.

2. Then press and hold the button marked "Fall Test", and the cage begins to scratch down.

3. When the falling speed reaches the calibrated action speed of the industrial fall arrester, the anti-falling safety device acts quickly and stops the suspension cage on the guide rail frame.

4. Normally, the braking distance of the suspension cage should be 0.3-1.2m from the start of the heavy fall arrester to the stop of the suspension cage.

The braking distance is measured and calculated by the following method:

S = L PI m Z / 2: S: braking distance mm; L: indicating pin end displacement mm; m: gear modulus; Z: gear teeth.

In addition, the measured L value is greater than 8 mm.

- No information

-

1. Design objective of electronic crane scale network management. (1) Adopt advanced distributed data processing techno…

-

Electronic crane scale bearing platform installation to focus Electronic crane scale can be installed generally on the li…