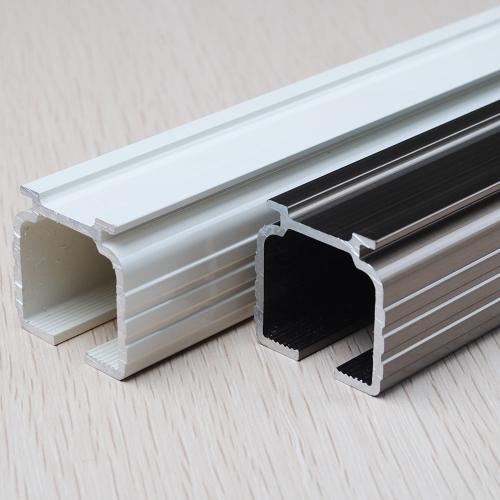

Selection and Use of Aluminum Alloy Track

Keyword:Aluminum Alloy Track Time:2019-1-6 11:29:15

In the rapid development of science and technology, China's society is also making continuous progress. In every industry, there will be the rise of large and small enterprises, and some enterprises will grow rapidly. In the lifting industry, the same is true. Aluminum alloy track plays a very important role in the lifting industry. So how about this track? Why use this material to make tracks? How do you measure the supplier when you choose this system? Let's see the introduction below.

Firstly, compared with pure aluminum material, aluminum alloy is easier to process and has better durability than aluminum when producing a kind of equipment product. It has a wide range of applications and good decoration. Therefore, the use of aluminum alloy track is very suitable.

Secondly, the anti-corrosion performance of aluminum alloy is very good. There are many chemical substances in many industrial workshops. There are many strong acid and alkali substances. If other materials are used to make tracks, the equipment will be easily corroded. But the use of aluminum alloy track will not be so, aluminum alloy corrosion resistance is very strong, can be a good protection against damage to equipment.

Third, the cost of aluminum alloy is relatively low. For manufacturers, it is a big profit to be able to use better and cheaper materials to produce better equipment. The price of aluminum alloy is relatively low, so the track price produced with this material is also relatively much lower. Many manufacturers say that the use of aluminum alloys to make tracks has greatly improved the performance-price ratio, and customers do not have to hesitate for so long when purchasing equipment.

There are four criterias for measuring the suppliers of aluminum alloy track systems.

Standard 1: Quality of Products

The quality of the product can‘t be neglected when choosing any product, so when choosing the aluminum alloy track system, we need to check whether the quality of equipment materials is passed. Only by guaranteeing the quality can the equipment run effectively.

Standard 2: Manufacturing Process

Manufacturing process represents the strength of a manufacturer. After years of research, development and production process, professional manufacturers will sum up a set of manufacturing process which belongs to their own manufacturer. With the gradual maturity of manufacturing process, not only the quality of equipment, but also the production efficiency can be guaranteed. Thus, excellent equipment and reasonable price can be provided for customers.

Standard 3: Test Report

When inspecting the material quality of equipment, we must check whether their products have passed the test and test certification of the state authority, and also check their independent intellectual property rights and technical patents, so as to ensure the quality of manufacturers.

Standard 4: Field Visits

After the above steps, we will finalize a manufacturer that we are interested in. At this time, we can conduct field visits to personally study their qualifications, experience their services, see their manufacturing processes and venues, and then determine whether the manufacturer's value is worth choosing for ourselves.

After the above introduction, I believe you have more or less understood. Aluminum alloy track has many advantages, which can be reflected in the use of various industries. The equipment will be used more widely, function and appearance will be constantly improved and better. I also hope that when you choose a manufacturer, you can follow the steps mentioned above step by step to ensure that the quality of the equipment you choose is perfect, but also to ensure the efficiency of the equipment.

- No information

-

1. Design objective of electronic crane scale network management. (1) Adopt advanced distributed data processing techno…

-

Electronic crane scale bearing platform installation to focus Electronic crane scale can be installed generally on the li…