Attention to Running-in Period of Wire Rope Electric Hoist

Keyword:Wire Rope Electric Hoist Time:2019-1-6 21:47:33

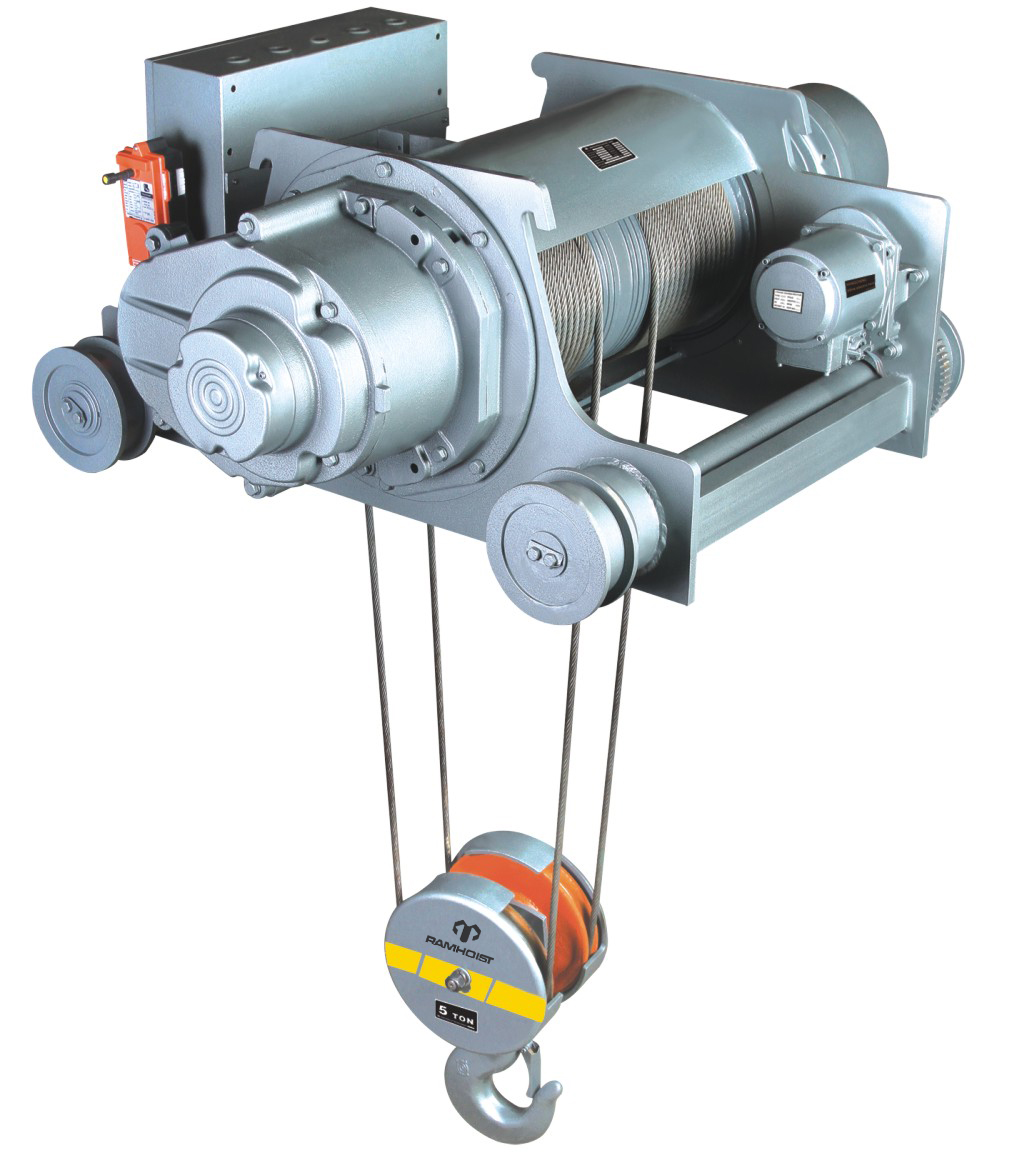

Wire rope electric hoist has a certain running-in period like other lifting machines. In order to improve work efficiency, it is very important to do its running-in work well in the process of using electric hoist. What are the matters needing attention in the running-in period of electric hoist? Next, the operation guide of wire rope electric hoist during running-in period is arranged for reference.

1. Looseness of electric hoist parts

Check whether the parts assembled are loose before using electric hoist. Because of the deviation of geometric shape and fit size, it is easy to be affected by alternating loads such as heating, deformation or vibration, shock, etc. at the initial stage of use. Accelerated the wear of electric hoist parts, resulting in loosening of previously fastened parts.

2. Bad lubrication of electric hoist fittings

It is difficult to ensure the uniformity of the clearance between the newly assembled electric hoist fittings because of the small clearance or the irregular assembly. It is difficult for the lubricant to form a uniform oil film on the friction surface to prevent the wear of the fittings. Even with lubrication operation, the normal lubrication effect can’t be achieved, resulting in abnormal early wear of accessories. Serious conditions will cause scratches and occlusions on the friction surface of precision matching.

3. Unsymmetrical surface pressure condition of electric hoist fittings

The new equipment is affected by the processing, assembly and adjustment of spare parts and other factors, resulting in fast wear rate, rough friction surface of equipment, small contact area of mating surface, and uneven pressure condition of spare parts surface. During the operation of wire rope electric hoist, the concave and convex parts of the surface of the parts are intertwined and friction, and the metal debris that is abrasives is worn down. As an abrasive material, it continues to participate in the friction, which improves the wear speed of the Parts' matching surface.

Therefore, in the running-in period, the contents easily cause wear and tear of the fitting surface, and the wear speed is fast. In this case, if overloaded operation, it will lead to the damage of electric hoist fittings, resulting in early failure.

Solution to Running-in Problem of Electric Hoist for Steel Wire Rope

1. Wire rope electric hoist in the early run-in period will generally appear parts wear out too fast, poor lubrication, loose parts, equipment oil leakage problems.

2. Before work, pay attention to check the use of grease, add at any time, lubrication method card reference equipment instructions.

3. Parts loosening is caused by vibration. Before working early, pay attention to check and tighten immediately after discovery.

4. Electric hoist oil spill is also caused by vibration and fever of electric hoist in operation. Daily maintenance should pay attention to the sealing condition of the equipment and adjust it in time.

Finally, during the running-in period of wire rope electric hoist, we should also pay attention to the vulnerable parts of electric hoist. Wire rope and hook, as the important equipment of wire rope electric hoist, should be regularly inspected for wear and tear of wire rope and hook, and be discarded and replaced in time. Electric control box and button switch control box control the whole line of electric hoist. When water or electricity leakage occurs, the circuit will be turned off actively. Protective measures should be taken for outdoor use. The guide rope can make the wire rope winding orderly according to the thread on the drum, avoiding the situation of cross groove and overlapping winding, which is easy to wear and tear, and belongs to the vulnerable parts. In the use of cable-stayed, installation is not standardized, etc. will lead to damage to the guide, can’t play the role of rope row, in this case, we should immediately stop using, replace the new guide.

- No information

-

1. Design objective of electronic crane scale network management. (1) Adopt advanced distributed data processing techno…

-

Electronic crane scale bearing platform installation to focus Electronic crane scale can be installed generally on the li…