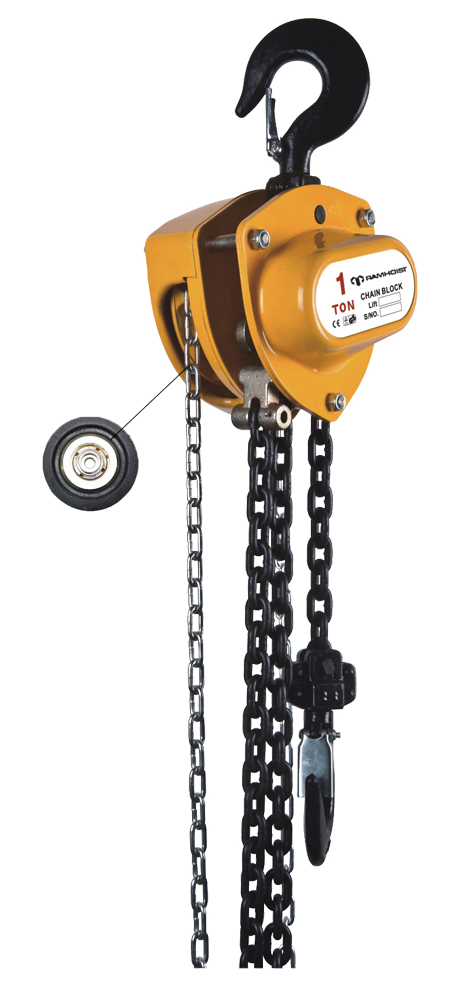

HSC chain blocks also named HS-C series chain blocks, which have advanced technology in the form of HS-Z hand chain blocks. HSC chain blocks are the kind of widely used and portable manual operating hoisting machine, they belong to Triangle Chain Blocks. we are professional exporter.

• Strong and pretty appearance designed by experts, low cost in maintenance and repair

• Durable and reasonable structure, high quality, as well as special and exquisite design

• Only need small hand pull force, which is very simple for workers to operate the blocks

• Small size and light weight make operators easy, comfortable and convenient to operate

• High reliability and excellent performance help our products more competitive than others

• Adopted open frame design, which can make them have the advantage of self-cleaning

• Side clearances, reduced headroom for simple maneuvering of heavy loads in tight places

• Equipped with the overload protection to completely avoid the situation of overloading

• Quick load sheave inspection can highly make sure the safety and security to our blocks

• A vital part, unique hand wheel cover is greatly used for guiding hand chain at any angle

• Reliable and compact inner structure of slot, which can highly avoid the chains be stuck

• Unique designed top hook can be installed with trolley directly and control easily

• High quality spur gear G80 alloy load chain provides a long service life to our products

• Excellent after-sale serve and market agent support are the advantages of our company

• 12 months warranty is the most significant commitment we can supply to customers

• The order and trail order are the principles that we can provide to our customers

Type HSC Chain hoist

Condition New

Capacity 0.5T-20T

Power Source Hand chain

Certification CE, GS

Lifting Height 3-15m

Color orange or as required

Inner part detail Double pawl

Shape Triangle

Material Forged alloy steel

Lifting speed Manual

Use Lifting Up/Down

Drive Mode Gear

Cover Thickening

Sling Type Chain

Break Load 4:1

Operation Hand operated

H.S. Code 84251900

HSC chain blocks also named HS-C series chain blocks, which have advanced technology in the form of HS-Z hand chain blocks. HSC chain blocks are the kind of widely used and portable manual operating hoisting machine, and they are very suitable to be used in the open air and the place without power. HSC chain blocks are suitable for short distance lifting of small equipment and cargo, and the lifting weight is generally no more than 100T.

The work principle of HSC chain blocks is that by dragging the chain and sprocket, the chain pulley and brake base are pressed together and rotated together, then the long tooth shaft turns the blade gear, short tooth and spline gear. In this way, the sprocket installed on the spline gear drives the chain which can lift loads stably. Adopting single ratchet friction disc brake, which can brake by itself under load. Under the action of spring, the ratchet pawl meshes with the ratchet wheel to make sure brake work safely.

The panel of HSC chain blocks adopt advanced technology of electrophoresis which offers more pretty appearance than the traditional blackening ones, and it works more close with the cover. The covers of nameplate and hand wheel are both made of 1.5mm material, which is thicker than the normal way of 0.8mm-1.0mm material. The guide wheel is fully steel forged, which can provide a long service life to our blocks. Compact inner structure is also one of the advantages of our products. Besides, the left and right wall plate adopt integral roller bearing, and the force is even during the test drawing. The new designed upper hook and lower hook adopt the famous brand, which covers the shortage of the traditional ones with steel-ball hook beam. Furthermore, forged swivel hooks with latches reduce twisting of chain and unintentional unhooking of load when chain is slack. Our HSC chain blocks are equipped with hardened load chain for flexibility and long wear. And the hand wheel is covered with guide slots to minimize jamming and slipping. Weston-type load brake requires no lubrication.

As the upgrade fixed pulley, the HSC chain blocks fully inherits all the advantages of fixed pulley. At the same time, it also adopts the combination of reverse and reverse brake reducer as well as chain pulley block. The symmetrical arrangement of two-level positive gear rotary structure make the operations of our chain blocks become more simple, durable and efficient.

Both HSC and CK type belong to Triangular type, compared with CK type, they have thinner cover and weaker hook, other features please refer to CK type, but price is cheaper. They are still very popular in middle level market, especially it has huge demand in Russia, Southeast Asia, Middle east and Africa. What’s more, compared with traditional features of the HS-Z type chain blocks, HS-C type hand chain blocks have smaller hand pull, higher safety factor and more beautiful appearance. Actually, default is bush but not bearing (needle bearing) for HSC and HSZ, bearing is only for CK type, please keep me informed if you need bearing on 2 side of load wheel for HSC type. HSC chain blocks have other names such as triangle chain hoist, triangle hand chain pulley block hoist for lifting, triangle body good quality chain pulley block, Triangle Hand Chain Power Source Chain Block, Triangle Manual Chain Block, Triangle type Chain Block, Triangle shape Chain Block, Triangle Chain Block, Triangle hand tools lifting chain pulley block, chain pulley hoist block.

RAMHOIST freely provide process designing and project designing. We also can help our customers to choose suitable equipment for them. The services we provide to our customers, including accompanying you to complete the acceptance of the equipment, drafting the construction scheme and detailed process, and completing process of export. Professional technicians provide installations and commissioning services. What’s more, the technical advisory we can provide to you for any time as long as you need.

HSC chain blocks can be widely used in factories, mines, construction sites, wharves, docks, agricultural production, shipping, warehouse for installation of machine, lifting goods, and they especially fit for the outdoor works and areas. In these areas, they have very important influences and applications. They can be used with trolleys to come true the lift of heavy goods both in left and right, and they also can hang on the top of the buildings or the beam of cranes.

1.Shell

The shell adopts high quality 1.5mm steel, which can make our products much stronger and safer. And alloy steel shell has a strong anti-collision ability, which has a function of effectively protecting the internal structure. What’s more, the shell is designed with flanged edge to keep smooth and steady operation even if the sprocket is drawn.

2.Brake System

Unique and high-efficiency double pawl brake system can greatly improve the brake safety factor, and more elastic pawl spring makes the product more stable.

3.Hooks

Adopting integral molding, and the loads is not easy to drop. After being forged and heat-treated, the alloy hook has a safety factor of 1:4. Besides, when the products are overloaded, the hook will not be brittle and will only deform slowly.

4.Chain

The chain is made of international manganese steel which is strong and hard to break. The chain has the advantages of excellent quenching process, anti-corrosion and rust surface. High strength chain, which is fine welding at the interface, after medium frequency induction quenching, and in line with ISO3007-1984 international standard. The chain changes common gourd which only can vertically down to a 45 ° angle pull from multiple directions, and also makes the adaptation scope more bigger.

5.Structure

Unique, pretty and reasonable structure, which accurately measures the spacing between the two plates to completely avoid the dangerous problem of chain winding.

6.Inner structure

Vital components of the inner structure are all made of high-class alloy steel, with high safety. Reasonable and compact inner structure is rustproof, which can provide reliable and durable operations to our products.

7.Sheave | Pulley

The well sealed bearing sheave has high strength and is hardened with four precision machined chain pockets. What’ more, high quality sheave can absolutely make our blocks used longer compared with others.

8.Gear and Spline Gear

Innovative and symmetrical arrangement of high speed synchronous gear with international standard, adopts the advanced Japanese technology. It doubles the wear resistance of ordinary calabash, as well as has more stable rotation and lighter hand tension than others.

9.Guide Wheel

Precision casting guide wheel has the small resistance to wear. Implementing strict size and weight check, which can ensure the good performance of guide wheel.

10.Chain Sprocket

High strength ductile iron chain sprocket has a better protection of lifting chain and is not easy to wear. The sprocket also can be equipped with mechanical processing of integrated shape lifting wheel with higher safety factor. And dual guide chain sprocket highly prevents the chain from shedding, twisting, and sticking.

11.Ratchet

Custom-made quick ratchet, using fine steel material which is very flexible and durable. And it also provides safety and security to our products.

12.Reverse Ratchet

Good quality reverse ratchet is a necessary component in HSC chain blocks, and has a strong impact resistance and pressure resistance to ensure the steady of operations.

13.Base

The base adopts advanced forging technology, which can highly make the blocks more durable, reliable and high-effective.

14.Shaft

Shaft is used to make sure the smooth and steady operations of lifting loads, and it also plays an important part in the process of lifting loads.

Two different kinds of hooks:

Normal hook

Fat hook

The price of Fat hook is slightly higher than normal hook, lots of customers choose normal hook

Others

①.Cautions

Do not exceed the prescribed lifting weight.

In the lifting process,the strength should be gentle, which can effectively prevent the chain from clasping.

Please check the chain block whether in good condition before using.

After using, please put it in a dry place.

Forbidding someone to walk or do any work under the weight.

The operator should stand the same plane with wheel when lifting.

②.Packing

There are two kinds of package, one is paper box with pallet, the other is plywood case.

③.Standard Part

Site photos of HSC chain blocks delivered to India

Site photos of HSC chain blocks 0.5ton, 1ton, 2ton, 3ton delivered to Brazil

Specifications

Type | Capacity (t) | Standard Lift (m) | Effort required to lift full load (N) | Load Chain | Test Load (t) | Weight (kg) | Additional Weight per 1m Lift(kg) |

Diameter (mm) ×chain falls | |||||||

HSC005 | 0.5 | 2.5 | 221 | 6 × 1 | 0.75 | 8 | 1.7 |

HSC01 | 1 | 304 | 6 × 1 | 1.5 | 10 | 1.7 | |

HSC015 | 1.5 | 343 | 8 × 1 | 2.25 | 16 | 2.3 | |

HSC02 | 2 | 314 | 6× 2 | 3 | 14 | 3.4 | |

HSC03 | 3 | 3 | 343 | 8× 2 | 4.5 | 24 | 4.6 |

HSC05 | 5 | 383 | 10 × 2 | 7.5 | 36 | 5.6 | |

HSC10 | 10 | 392 | 10 × 4 | 15 | 68 | 11.2 | |

HSC20 | 20 | 392 | 10 × 8 | 30 | 156 | 22.4 |

Dimensions (mm)

Type | Capacity (t) | A | B | H | D | C | |

HSC005 | 0.5 | 125 | 111 | 270 | 35 | 24 | |

HSC01 | 1 | 147 | 126 | 317 | 40 | 28 | |

HSC015 | 1.5 | 183 | 141 | 398 | 45 | 34 | |

HSC02 | 2 | 147 | 126 | 414 | 50 | 34 | |

HSC03 | 3 | 183 | 141 | 465 | 58 | 41 | |

HSC05 | 5 | 215 | 163 | 636 | 64 | 48 | |

HSC10 | 10 | 365 | 163 | 798 | 85 | 64 | |

HSC20 | 20 | 585 | 191 | 1000 | 110 | 82 | |