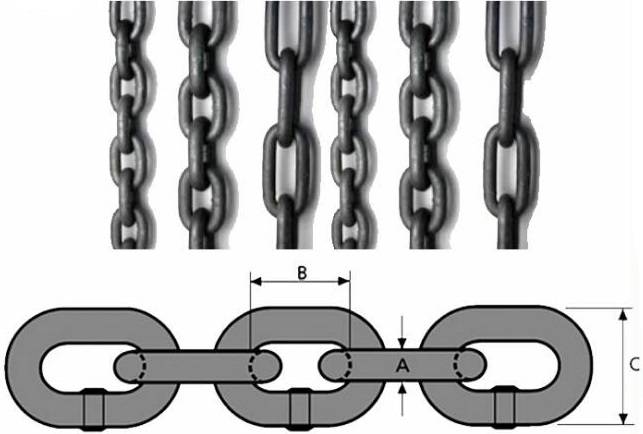

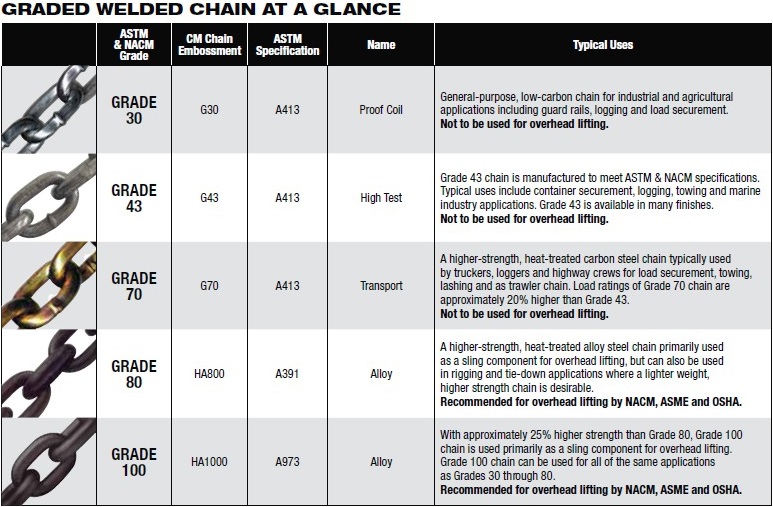

G80 Alloy Load Chains are manufactured from high quality alloy steel are designed for dropping anchors, reality construction, versatile lifting which can satisfy customers’ own requirement and are the most reputable and reliable products in the lifting industries.It is also called G80 load Chain or G80 alloy Chain.

• High quality and grade alloy steel, material integrity, excellent core ducitility

• 4 times of the safety factor, 2.5 times of the verification load

• Wear, abrasion, durable, resistant to corrosion &rust; durable

• Each link proof tested to assure weld and material integrity, secure welding spot

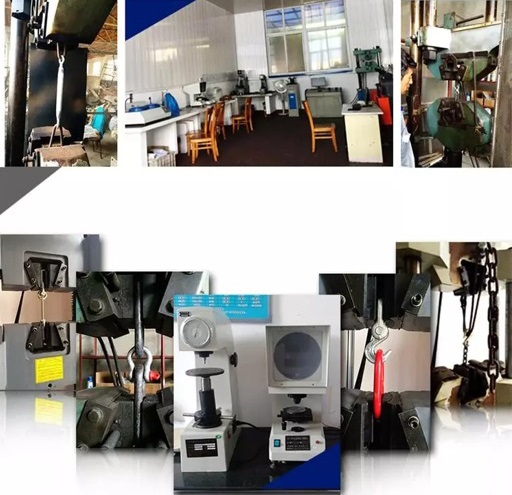

• Several checking procedures in case of defective products

• Heat treated, Tougher and more reliable for lifting application

• Long service life, guarantee of quality, Standard specifications

• Non standard chains or other size can be customized by customers requirements

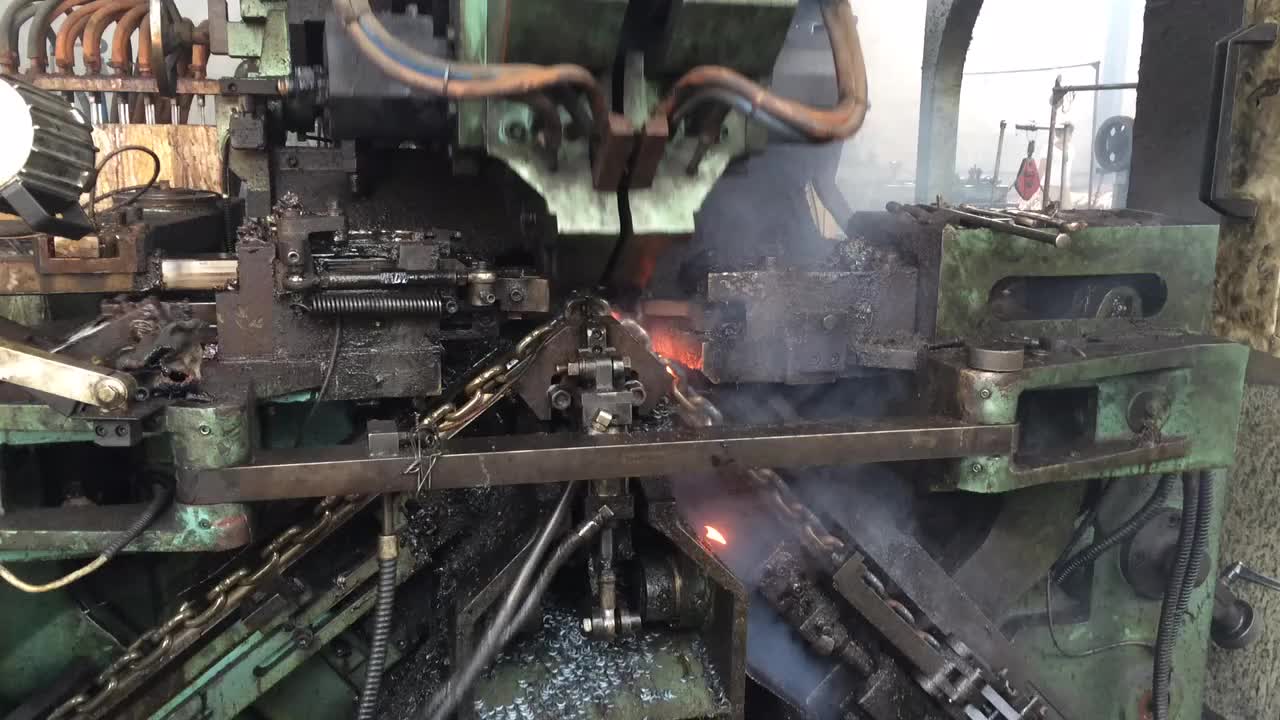

• Automatically, Uniformity, Welding, Precision accurate, Strictly control

• More precise treatment and can bear high strength

• Be economical and with a good strength-to-weight ratio

• Great reputation and be reliable products in the lifting industries

• Decent price and low price and on time delivery with great package

• Safe and Security adhere to the contours of the load

• Provide excellent lifting in various condition and applied to many filed

Capacity 4mm-32mm

Type Short link, Medium link, Long link

Size All kinds of type or according to customer's design

Usage Drag, Transmission, transportation, load, lifting, Conveyor, anchor, strapping, lashing, hoist, construction

Sling Type Chain

Surface Treatment Plastic coated, self-color, polishing, electrogalvanized, hot-dip, etc.

Structure Welded Chain

Payment Terms L/C, T/T, D/P, Western Union

Sample Supplied

OEM Acceptable

Standard Ordinary mild steel link chain

Logistics By sea, airway, express, etc..

Test Welded test, breaking loading test

Package Gunny bag and iron box, wooden cases, standard Iron drum with pallet, plastic pail or as requirement, etc.

Safety Factor 4:1

H.S. Code 731582000

| PDF DOWNLOAD |

G80 Alloy Load Chains are manufactured from high quality alloy steel are designed for dropping anchors, reality construction, versatile lifting which can satisfy customers’ own requirement and are the most reputable and reliable products in the lifting industries. The main preponderance of G80 Alloy Load Chains is that they are durable for the more complex condition even in corrosion and rust. What’s more, G80 Alloy Load Chain has long service life for firm quality and multiple testing. The broken of welding spot is hardly to be found in light of precise technology.

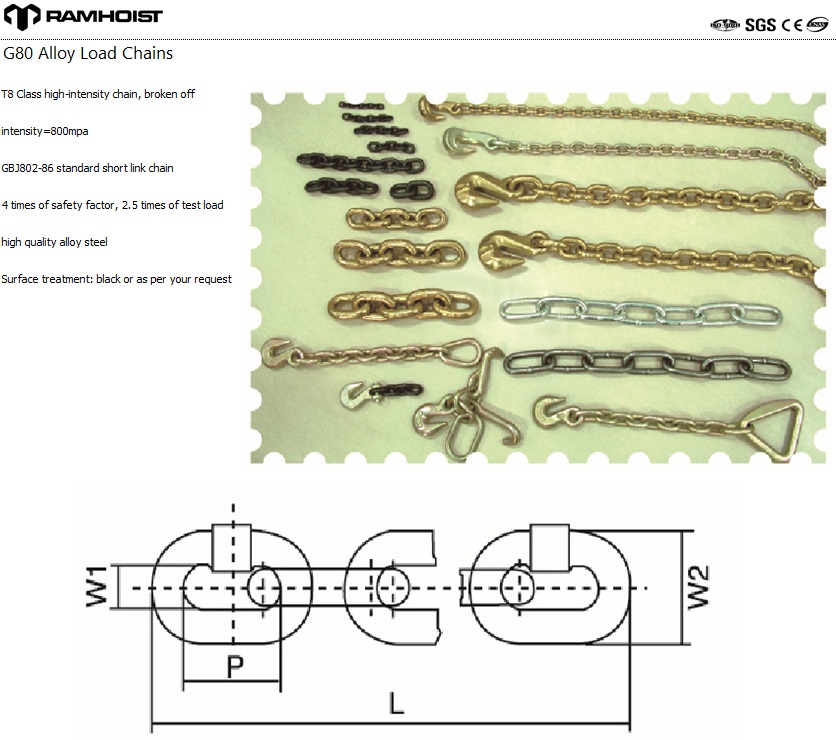

Grade 80 (T) heat-treated alloy steel Chain (T8 Class high-intensity chain, broken off intensity≥800mpa) is designed for Chain Slings, rigging slings (for lashing), Dragging, lifting assemblies (Lifting chain, lifting beam, chain for hoists, cranes, winches, and other material handling equipment), and load binding, logging, towing for industrial lifting applications and with superior performance, It is used in Anchor, lifting, Terminal tractor, strapping, Automotive anti-skid, nets down, home decoration, public protection, mine, cement requirement and municipal engineering, garden decoration etc, It is made from superior and special analysis alloy steel, hardened and tempered by strict control of the process:

1. Our stretch correcting machines can check chains link by link, can guarantee weld quality, If welded place break when stretch, then the chain will not pass the test, as waste product;

2. After finish produce, will choose several links randomly, do the breaking test. In other words, It's quenched & tempered before proof testing and the ultimate tensile strength is over twice that of ordinary steel chain. It has a high resistance to impact and (Tensile strength following heat treatment) meets or exceeds critical requirements of National Standard GBJ802-86, GB/T20947-2007 short link chain lift standard (idtAS2321, International Standard (ISO3077-2001), American Standard (NACM, ASTM), European Standard (EN818), AS/NZS Standard Short link Chain for lifting purposes”) for overhead lifting applications, It can easily withstand more abuse, abrasion resistance, greater load lifting per size. Grade 80 Alloy Chain meets industry minimums of 15% elongation factor. Alloy chain is black lacquer finished, galvanized(white or color), self color (Ecru--polished), plastic spraying, It is lighter to handle for lifting operations, The best for towing, recovery and safety chains, some customers even choose G100 chain for higher quality request.

There are three standard grades for lifting chain (also known as loading/load chain): grade 80 lifting chain, grade 100 lifting chain, grade 120 lifting chain, the lifting chain is specifically designed for overhead lifting applications, These grade of lifting chain has a good strength-to-weight ratio and excellent durability, of these three grade, G80 Alloy Steel Weight Lifting chain loading/load chain is the most economical.

G80 Alloy Load Chains are made to a fully-killed fine austenitic grain process. these alloy steel chains are made by the electric welding or gas welding process. The material shall be heat treated which includes quenching and tempering. Material's composition conforms to the chemical requirements for carbon, phosphorous, sulfur, nickel, chromium, and molybdenum. The material conforms to the mechanical property requirements for breaking force and elongation and to the dimensional requirements for the appropriate size chain. All chain is tested to at least the proof load.

The Grade designation is 1/10 of the minimum breaking strength in newtons divided by two times the nominal cross-sectional area of the chain in square millimetres. The values stated in either SI units or in other units shall be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system must be used independently of the other, without combining values in any way. The chain comes with bent hook/ assembled grab hooks/ clevis grab hooks to use, Every link is quenched, tempered and then proof tested, Although this chain uses Alloy lifting chain and Alloy hooks, the chains here are *NOT* suitable for overhead lifting (our tie down chain assemblies are not designed for overhead lifting due to the supplied hook).

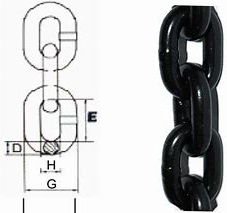

Normal Material is Alloy steel 20Mn2 or 20MnSi, 25MnV, 23MnNiMoCr, Safety factor: 4:1, The breaking elongation of chain using alloy after heat treatment ≥ 17% length customized, OEM accepted, normally G80 marking (“G80” stamped on the chain link) for every 6 chain or at interval of one meter at least or as per your request, The High-dynamic round steel chains are stamped with the serial number; pls inform Diameter *pitch (inner length )*outside width and Surface treatment of chain before you put order. Some suppliers use G70 heavy duty lifting chain instead of G80 to let the price down, that will lead lot of quality problem later.

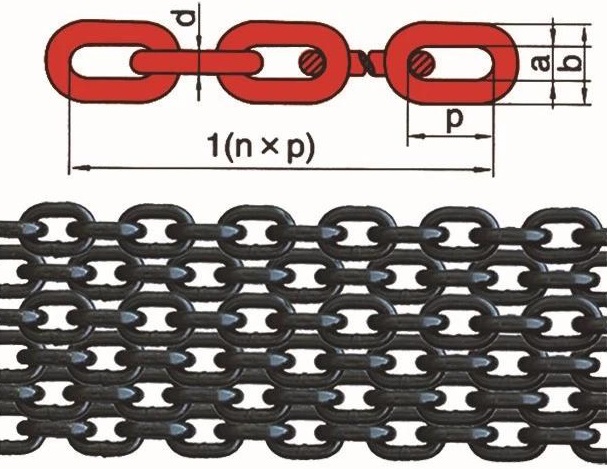

We also have G30, G40, G70 chain except G80, details is as follows:

| Material | carbon steel | stainless steel | Q195 | Q235 | 20Mn2 | |

Surface treatment | Electro galvanized | Hot dipping galvanized | black oxide | painting | ||

Standard | ordinary mild | Short link chain | ||||

Medium link chain | ||||||

Long link chain | ||||||

Germany Standard | DIN5685A/C short/long link chain | |||||

DIN763/DIN764 link chain | ||||||

DIN766 short link chain | ||||||

Grade | G30 | G43 | G70 | G80 | ||

Usage | Lashing, transportation, transmission, construction, fence | |||||

Shop decoration, swing, fishing, lifting chain, hardware chain | ||||||

Anchor chain, snow chain, animal chain, elevator balance | ||||||

Packing | Gunny bag | plastic reel | plastic bucket | steel bucket/ | ||

Technology: Welded (Automatic welding), Drop forged, Casting.

G80 Alloy Load Chain also named G80 lifting chain, G80 Chain, G80 steel Chain, G80 alloy Chain, Grade 80 chain, G80 alloy steel link chain, G80 steel link lifting chain, G80 Welded Galvanized Lifting Chain, G80 alloy standard or nonstandard load chain, T8 grade high strength chain, Alloy steel g80 load chain with black color for hoist, High Grade Alloy Steel G80 Load Chain, G80 EN818-7 Alloy steel Calibrate hoist load chain, G80 high strength lifting chain, G80 Alloy Steel Load Lifting Chain, alloy load lifting g80 link chain, Heavy Duty Alloy steel welded G80 load chain, Lashing Rigging Load Chain, Link Chain Fastener G80 Lashing Rigging Load Chain, High quality black alloy steel load chains, Galvanized black chains, Heavy Duty Grade G80 Galvanized Alloy Iron Round Link Welded Lifting Load Chain, G80 Alloy Steel Weight Lifting chain loading/load chain, Heavy Duty lifting steel chain, galvanized anchor chain g80 alloy load chain, G80 En818-2 Calibrated Load Alloy Steel Lifting Chain, G80 Black Chain, Heavy Duty G80 Alloy Steel Chain Load Chain, self color lifting chain G80 type self color load chain.

1. Material:

Alloy steel, high tensile, high working load strength with minimum weight

2. Marks

Mark sign T8 or G80 as requirement, permanently embossed with desired marking for easy identification and traceability.

3. Safe factor

4:1 (4 times breaking force test), Minimum breaking load is 4 times the W.L.L.

4. Proof test

Proof tested at 2.5 times the Working Load Limit, Do 2.5 times of WLL manufacturing validation strength tensile test.

5. Structure

Welded Chain

6. Surface Finish

Self-color, polishing, blacked (tempered)/black oxide/ Black painted, powder coating, hot-dip, galvanized

(Electro-galvanized/Zinc Plated), Blue white zinc plated, blue painted, red painted, Painting, Plastic spraying.

Normally Alloy chain is black lacquer finished for lifting purpose, Black rust preventative coating

7. Load chain hardness

38HRC to 42 HRC

8. Technology

Heat treated, drop forged, tempered and quenched

9. Manufacturing Equipment

Automatic knitting chain machine, automatic welding machines, automatic correction machine, heat treatment machine, loading test machine, polish machine.

10. Package

Normally Gunny bag or iron/ steel drum (Chain Drum) with pallet

However, Ton bag, Wooden box/case, Iron drum, Plastic bucket/drum, Carton with Pallet, plastic reel bundle, pallet etc is accepted, parts of details are as follows:

1. Gunny bag in bulk/gunny bag + pallet

2. Woven bag + pallet

3. Iron drum + pallet

4 .Plastic drum + pallet

5. Carton and pallet

6. Plastic reel and carton + pallet

7. According to your requirements

Others

More precise treatment and can bear high strength.

can be manufactured or cut in any diameter and length according to your special purpose.

Test Certificates available upon request.

Some tips:

Chain has been around for over a thousand years. It is one of the most versatile and reliable ways to lift, tension and tie down materials in a variety of applications. In the past, people would use any type of chain to lift something, tie down a load or tow a vehicle. Proper inspection, safety procedures and general standards of practice for chain were lacking.

In recent years, due to safety concerns and regulations, the industry has begun to differentiate between various materials and chains such as grades of G80 Alloy Load Chain and the specific applications they should be used for. ASTM (American Society of Testing & Materials), ASME (American Society of Mechanical Engineers) and OSHA (Occupational Safety & Health Administration) began to publish safety standards and regulations for the manufacturing, testing, use, inspection and repair of chain.

Chain Grades

One of the safety measures implemented was to place chain in Grades based on the ultimate breaking strength of that chain. This number is what we see today G30, G43, G70, G80 & G100 and the common chain grades. The number after each letter is N/mm2. For example, G80 means that the maximum stress on the chain at ultimate strength is 800 newtons per millimeter squared.

Working Load Limit (WLL) of Chain

The other safety measure was identifying which types of chain are appropriate and strong enough for overhead lifting. Anytime we move or lift a load it is dangerous. Moving a load along the ground has the advantage that the ground is supporting the load. We have to overcome the coefficient of friction to move the load. The chain’s working load limit does not have to match the weight of the load. It needs to be able to handle the tension applied, which is based on the surface that it is being moved over plus some fraction of the weight of the load. This can be calculated using formulas.

If we lift that same load off the ground, we now have to overcome gravity. The chain’s working load limit will have to be of sufficient strength to support the weight of the load plus any additional forces imposed by angles and hitch type(s) used.

Which Chain Grade Should Be Used for Which Type of Application?

Alloy Chain Grade 80 or Grade 100 should be used for overhead lifting. G80 Alloy Load Chains are most used in chinese markert, ASTM states that alloy chain shall be able to elongate a minimum of 20% before fracture (7.3.5). To ensure that alloy chain consistently meets this requirement, ASTM requires the use of certain alloying elements in the manufacturing of the steel for alloy steel chain. These alloys can vary from company to company, but some key requirements are specified by ASTM. The alloy properties also improve the wear and tear that the chain will experience. Note that when chain is in use, no amount of stretch is allowed.

Carbon Grade 70 chain is a “heat treated” carbon steel chain that has no alloying elements added to the steel. This chain will elongate before breaking but does not have the properties needed for overhead lifting; therefore, Grade 70 chain is not intended for overhead lifting. This chain is designed for use as a tie down chain or lashing for transportation. Grade 70 chain has a gold chromate finish to help resist corrosion from continuous exposure to the elements and the rigors of highway use, such as road salts in the winter.

When any type of overhead lifting is required, use only alloy chain slings unless specified by the manufacturer.

The preferred chain for load securement is Grade 70, but any grade of chain can be used for tie downs or tensioning. You have to know your tensions in order to select the proper chain. Refer to load securement safety standards FMCSA (Federal Motor Carrier Safety Administration), CVSA (Commercial Vehicle Safety Alliance), WSTDA (Web Sling Tie down Association) or the state regulations for more information.

Test certificate of load chain Φ7.9 x 23.0 mm

Site photos of G80 alloy steel goldon galvanized tie down chain with G80 bent hook

Specifications

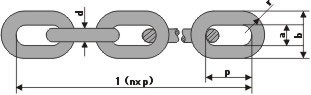

Size d*p (mm) | Width (mm) | WLL (t) | MPF min. kN | BF min. Kn | N.W. (kg/m) | |

Inside min. W1 | Outside W2 | |||||

4×12 | 5 | 13 | 0.5 | 12 | 20.2 | 0.28 |

5×15 | 6.25 | 17 | 0.8 | 19 | 31.6 | 0.35 |

6×18 | 7.5 | 20 | 1.1 | 27 | 45.4 | 0.79 |

6.3×19 | 7.88 | 21 | 1.25 | 30 | 50 | 0.8 |

7×21 | 8.75 | 23 | 1.5 | 37 | 61.6 | 1 |

8×24 | 10 | 26 | 2 | 48 | 80.6 | 1.4 |

9×27 | 11.25 | 30 | 2.5 | 61 | 102 | 1.8 |

10×30 | 12.5 | 33 | 3.2 | 76 | 126 | 2.2 |

13×39 | 16.25 | 43 | 5.4 | 128 | 214 | 3.8 |

16×48 | 20.8 | 59.2 | 8 | 201 | 322 | 5.7 |

18×54 | 23.4 | 66.6 | 10 | 254 | 407 | 7.3 |

20×60 | 26 | 74 | 12.5 | 314 | 503 | 9 |

22×66 | 28.6 | 81.4 | 15 | 380 | 608 | 10.9 |

26×78 | 33.8 | 96.2 | 21.2 | 531 | 849 | 15.2 |

32×96 | 41.6 | 118 | 31.5 | 804 | 1290 | 23 |

-

Cargo Trolley is an alternative to traditional with roll arounds handling equipment for handling tools. Applica…...

-

Hydraulic toe jacks are designed to lift heavy machinery and other similar type loads when there is a fair amou…...

-

Screw jack is powered by human through screw pair drive, screw rod or nut sleeve as the jacking part As a commo…...