Screw jack is powered by human through screw pair drive, screw rod or nut sleeve as the jacking part As a common lifting and jacking tool on automotive, bridges, ships and machinery industries. Hook screw jack can hook lower position goods using hooking leg.

• Made of high-grade steel material, safe and reliable

• Exquisite design, Light weight, easy to carry

• High power and High quality with most competitive price.

• Tested to 150% of rated capacity keep it is safety used.

• Suitable for lifting auto, truck service, farm, and shop use.

• Used for automotive, industrial, agricultural, marine recreation and construction applications where lifting,

pushing, spreading, bending, pressing or straightening is required.

• All models work in upright or horizontal position where strength is required.

• Built in one piece hydraulic unit with pump through action designed to prevent the handle from locking up.

• With lifting body and Safety crank with folding handle.

• Lifting either with fixed toe or on clawed head.

• All construction components standardized.

• Low expenditure of force through optimal ratio.

Capacity 3.2Ton-320Ton

Lifting Height 110mm-200mm

Min Height 200mm-540mm

Use Lifting Tools, large tonnage mechanical jack

Material Cast Iron, Steel

Model Number: LD

Type Mechanical Jack, Hydraulic Jack

Painting: Static electricity painting

Color Green red yellow blue or Customized

Certification CE ISO

Place of origin China

Warranty 1 Year

H.S. Code 84254210

Use Area Automotive Industry, High-speed rail, Railway construction

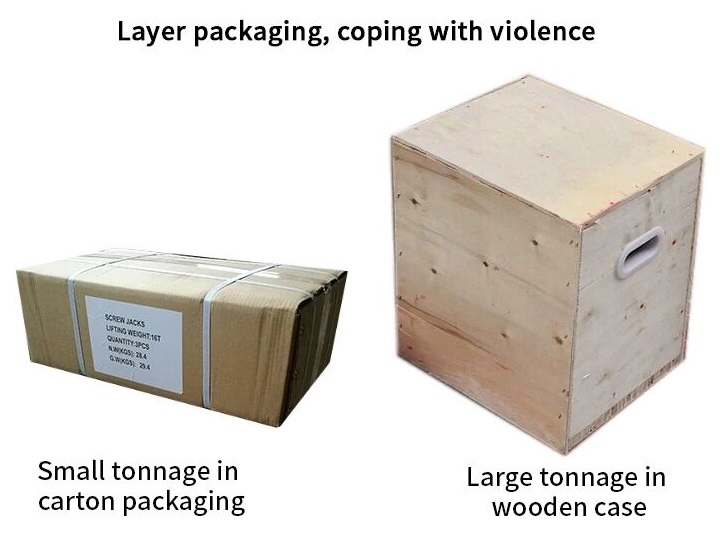

Packing: Standard export packing [Wooden Box, Color Box(Inner package: color box

Outer package: carton)], Neutral packing, OEM, Customer's Designs and Logos are Welcome

| DOWNLOADS |

Screw jack is powered by human through screw pair drive, screw rod or nut sleeve as the jacking part As a common lifting and jacking tool on automotive, bridges, ships and machinery industries. Hook screw jack can hook lower position goods using hooking leg.

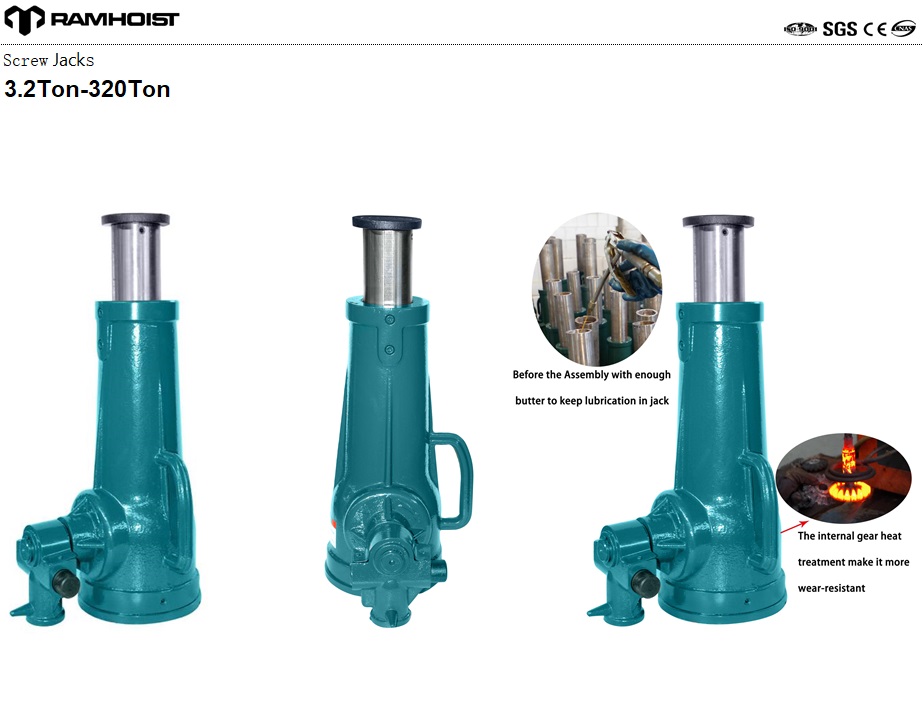

Screw Jack is suitable for general engineering applications, which is constructed of high-grade and high strength steel and built to exacting standards for quality and durability. Body and cap is made of graded cast iron, screw is made of steel, threads are machine cut - square threads and has a serrated swivelling cap. The internal nuts that fit the screws are made of copper alloys, making the jack safer and more reliable with longer service life through their high mechanical properties and good lubricating performance; The inner part adopts worm and worm gear transmission with high transmission ratio and high work efficiency; The worm gear is provided with deep groove ball bearing and thrust ball bearing, and the worm is provided with powder metallurgic casing and thrust ball bearing, which bear radial and axial forces and make lifting and lowering of the jack more stable; The inner part adopts ratchets and teeth. Move the teeth to realize forward and reverse rotation of the rocker; The cast shell ensures the product works safely and reliably.

It is heat treatment and welding, structure simple, easy handling, durable. The high quality is stable, safe and reliable; Top and hook lifting combination, easy for low position operation. It can be used for lift goods. The jack is available with either ratchet arrangement or plain four way head suitable for operation with ratchet or tomy bar respectively.

Common screw jack relies on screw self-locking effect by supporting weight, simple structure, but the transmission efficiency is low, return slowly. Lower screw jack without self-locking effect, is equipped with brakes. Relax brakes can be self-rapid decline in weight, shorten turnaround times, but this jack more complex structures. Jack screw long-term supports heavy loads, max weight reached 320 tons, used widely. After the bottom is mounted horizontal screw rod, the machine can make the weight for the small distance traversed.

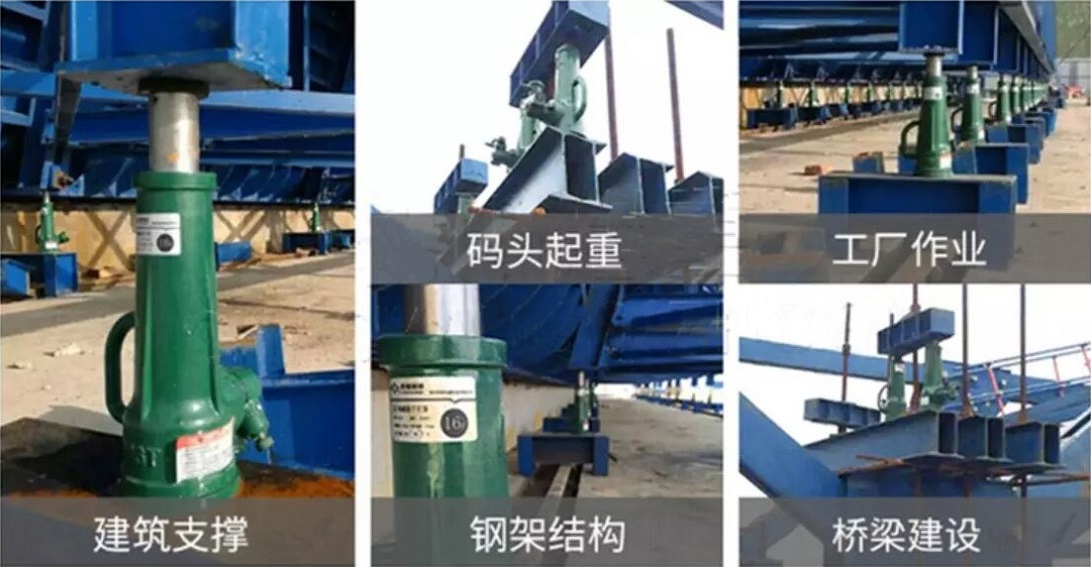

Screw Type Hydraulic Jack is the simplest & sturdiest types of the jacks which applied in machinery equipment, construction, railway track of installation and maintenance, and transportation of heavy loading and unloading, automobile tractor repair, ect, and are also widely used in factories, ware houses, bridge construction, engineering construction, Oil Fields, Ship Yards, Mining Operation, fabrication, Construction & Heavy Duty Industrial Maintenance & Establishments and other department of lifting operation.

A mechanical screw jack has a compact structure, small volume, is light weight and easy to carry, we supply all kinds of screw jack with high quality and competitive price.

This Lifting Screw Jack lifts and precisely positions a variety of loads, while also functioning as a Lifting Screw Jack stand for load support (Mechanical Car Screw Jack). An ideal choice for construction projects, bridge stabilization, supporting and lifting mobile homes, buildings, industrial equipment, and more

It is also called Screw Type Hydraulic Jack, hand mechanical lifting tool based gear screw jack, Lifting Jack, Car hydraulic jack, mechanical screw jack, manual mechanical car screw jack, Mechanical Car Jack, Vehicle Repair Jack, lifting manual mechanical bottle screw spiral jack, Screw Jack Car Jack Spiral Jack, Car Jack, Car Screw Jack, spiral jack, Screw Hydraulic Rail Lifting Jack, Manual Powered Screw Jack, Portable Manual Car/Garage Screw Jack for Lifting, Lifting Screw Jack, Screw Hydraulic Rail Lifting Jack, Lifting Tool Repair Tool.

The whole body is cast, anti-oxidation paint sheel, the body is not prone to rust

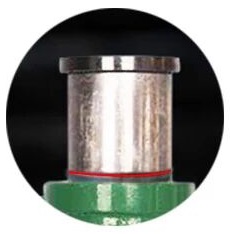

2.Sleeve

Precision grinding lifting sleeve, Druable, Buit-in red warning line

Fine grinding sleeve, High-strength steel cast material for both upper and lower chassis

3. Ratchet bite

The ratchet bite is tight and not easy to get rid of

4.Base

Integrated casting thick base, Use more smoothly.

5.Top

Steel top plate (steel cover) is hard and hard High-strength steel cast material for both upper and lower chassis

6. Material

Nodular cast iron Cast one-piece body has desirable stability

7.Red warning line (safety limit position)

The red line indicates the maximum jacking height, please do not jack up further

8.Thickened stoved enamel

The primer of multiple layers is baked, so it not easy to be peeled of. This thickened enamel has significant resistance against corrosion and rust

Please pay attention to the follows

a, The machine should put on a flat place when using, and avoid deflection.

b, It is strictly prohibit the lifting height more than the product requirement limit, or else leading to the Guide fall off from the machine.

c, Forbid the overload operation.

d, Don’t put your finger and feet below the object when using .

f, Before using keep the Guide lubrication, keep the machine clean, after use pay attention to put lightly, not collision and arbitrary throws.

Use method:

1.Before use, need to add oil, oil hole on the crank handle. In order to ensure better use of results.

2.According to the weights the weight of reasonable selection of appropriate tonnage Jack, do not overload use.

3.The first step is to ensure the landing base level. The height of the jack is lower than the height you want to lift.

4.Insert the handle into the handle hole and move the handle up and down. If there is a sound, turn the switch 180 degrees (the marked part of the graph is pressed down), shake the handle up and down, the weight will rise. When the red line appears on the elevator, stop the handle immediately.

5.If you want to decline, turn the switch 180 degrees, shake the handle up and down, the weight began to decline.

Notes:

1.Can only be used upright or horizontal, can not be tilted.

2.Turn the switch 180 degrees, and then try to shake up.

3.Jack must be put on heavy objects, there will be pressure, will rise up.

4.Look at the groove and the key sheath of the lifting tube whether is separated, if separated, please adjust, then shake up and down to see if it can rise.

5.Strength of jack:QL Screw Jack is a new series of national stereotypes. It has the strength of compact structure, small volume, light weight, convenient carrying, can stand upright and horizontal. at the same time, Jack’s parts are(Lift tube is)NO.45 heat treatment, improve the internal quality of parts, the use of performance, extend the service life of parts, improve product quality. Especially the ratchet and gear are forged, making the parts within the organization more closely, strong, solid. The force part of the jack is not in the shell, it is inside the components.

6.Weakness of jack: Lifting speed is slow

7.Usage:This product is suitable for High-speed rail / railway / subway / warehouse construction and bridge installation.

8.Check: The products were delivered after three inspections. Every component is tested. The last step in the process is to roll down the screw, that is, to test the product, to confirm the quality of good after delivery.

QL Screw Jack is a new series of national stereotypes. It has the advantages of compact structure, small volume, light weight, convenient carrying, widely used in factory warehouses, bridges, docks, transportation and construction engineering departments of the lifting operation.

Working Principle

Mechanical jacks is one type of manual lifting tool, which has the advantage of compact structure,reasonable use of the swing of the rocking rod, so that the pinion to rotate through a pair of bevel gears, and running,to drive the screw to rotate, push the elevating sleeve, there by the weight rises or falls.

Instructions

1.Before use, it is necessary to check whether the jacks are normal, whether the parts are flexible, add lubricating oil, and properly estimate the weight of the weight, use the appropriate tonnage, and avoid overload use.

2.Adjust the way of holding the support tooth on the rocker: first, turn the rocker directly clockwise to make the lifting sleeve rise rapidly.

3.Insert the handle into the rocker hole and move the handle up and down, lifting the weight.The removal handle should be stopped immediately when the red line appears on the lift sleeve.You need to move the support tooth in the opposite direction when you need to go down, the weight begins to fall.

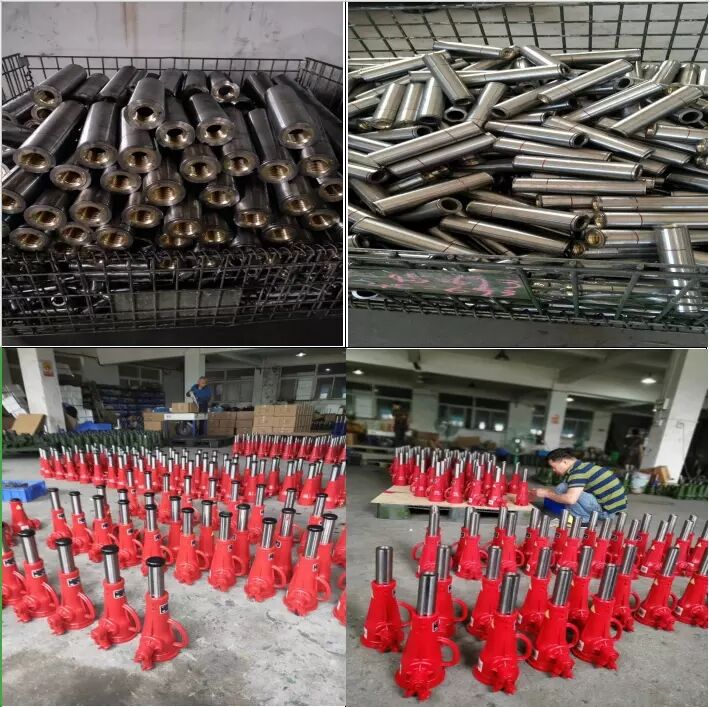

Workshop show

Product package

Aplication:

Specifications

Model | Capacity(t) | Min.H. (mm) | Lifting.H. (mm) | N.W(kg) | Qty/Ctn (pcs) | Packing size (mm) | 20’FCL (pcs) |

QL3.2 | 3.2 | 220 | 110 | 4.9 | 4 | 535x260x160 | 4400 |

QL5 | 5 | 250 | 130 | 6.4 | 4 | 550x287x180 | 3400 |

QL8 | 8 | 260 | 140 | 6.5 | 4 | 550x287x180 | 3500 |

QL10 | 10 | 280 | 150 | 8.6 | 3 | 510x315x195 | 2550 |

QL16 | 16 | 320 | 180 | 11.9 | 3 | 560x365x225 | 1800 |

QL20 | 20 | 325 | 180 | 12.5 | 3 | 560x365x225 | 1800 |

QL25 | 25 | 275 | 130 | 11.1 | 3 | 445x420x235 | 1900 |

QL32 | 32 | 395 | 200 | 20.1 | 2 | 490x325x265 | 1100 |

QL50 | 50 | 452 | 250 | 36.2 | 1 | 500x390x310 | 610 |

QL100 | 100 | 452 | 200 | 71.7 | 1 | 500x287x180 | 300 |

QL200 | 200 | 472 | 200 | 130 | 1 | 570x490x420 | 170 |

QL320 | 320 | 540 | 200 | 207 | 1 | / | / |

-

Cargo Trolley is an alternative to traditional with roll arounds handling equipment for handling tools. Applica…...

-

Hydraulic toe jacks are designed to lift heavy machinery and other similar type loads when there is a fair amou…...

-

Screw jack is powered by human through screw pair drive, screw rod or nut sleeve as the jacking part As a commo…...