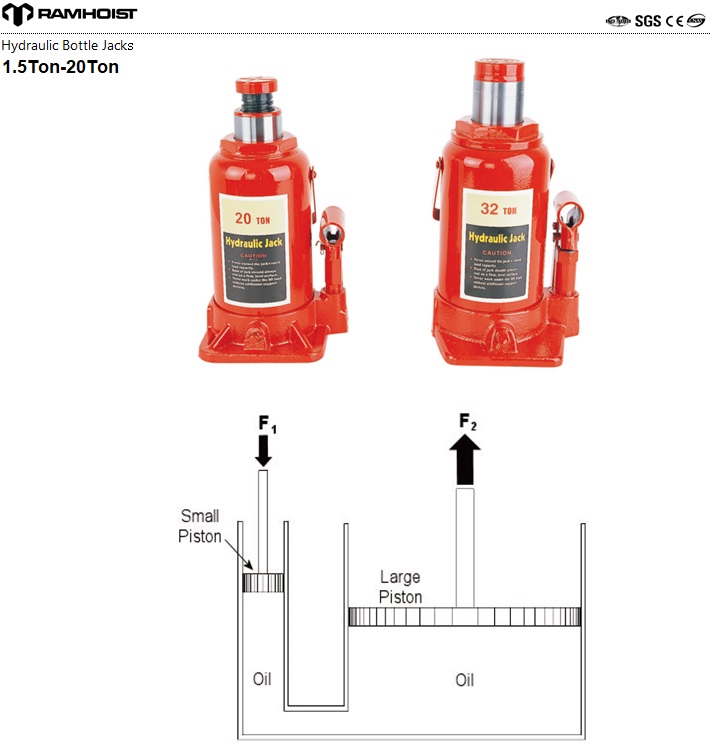

Hydraulic Bottle Jacks, toughly built and high grade powder coated, are designed for lifting and transportation of machines or heavy objects and repairing or assembly jobs, which can be used vertically (not upside down) or at any angle to no more than 5 degree from vertical position. If your hydraulic bottle jack not lifting or if you need hydraulic bottle jack parts diagram, Please do not hesitate to contact us.

• Light weight, compact, small, and robust with highly economical prices

• State of the art design reduces repair time with gross-groove contact for maximum grip

• Hydraulic Lift and handle included with full parts availability for convenient use

• Simple and strenuous operation with fully and excellent after-sale service provided

• 100% sealed which greatly improved safety with high strength forging base

• Welding and reinforced structure and construction ensure it is not easy to leak

• Built-in safety valve prevents from overloading the jack with high reliability and durability

• The piston rod and piston head are one-style structure with high strength.

• Used widely for automotive, industrial, repairing, agricultural and so on.

• Meets ANSI/ASME PALD & CE/GS standards and experienced strict test

• All models are equipped with three piece handles and two rockers

• Easy to use, portable to carry, transport, disassemble and store with good mobility

• Work in upright, angled, or horizontal, stroke is reduced to 70% when used horizontally

Capacity 2Ton-50Ton

Structure Hydraulic jack

Use Lifting and positioning

Drive Mode Manual

Certification CE, ISO

Condition New

Max Height 405mm

Bar/ handle Two

Standard High quality

Min Height 148mm

Customized Available

OEM Welcome

Warranty 1 year

Color Red, blue or as request

Power Supply Hydraulic

H.S. Code 84254210

Package Carton case with pallet

Hydraulic Bottle Jacks, toughly built and high grade powder coated, are designed for lifting and transportation of machines or heavy objects and repairing or assembly jobs, which can be used vertically (not upside down) or at any angle to no more than 5 degree from vertical position.Tested longer wear life due to internally machined oil passages, hydraulic bottle jacks have smooth bearing surfaces and close tolerances. The prominent feature of them is that the hydraulics are powered with high quality oil, which offers better corrosion resistance and high/low temperature flexibility and can be used in temperatures ranging from -20º to 70º C and not affected by temperature extremes.

Hydraulic bottle jacks are equipped with solid cast iron forged steel base, steel cylinder housing, pressure cylinder and oil deposit form one integral part, which provide more strength and safety to the jacks resulting in a stronger jack. A cast iron base bears the load and a cleated non-slip lift cap keeps it stable. What’s more, fitted with a built-in overload protection valve, two piece ‘pumping’ handle, operates hydraulic release, Any pressure loads produced by the vehicle axle tilting are absorbed as the piston never comes into contact with the cylinder, Therefore the jack will not be damaged even if the vehicle tilts. Used on a firm level surface, you may simply place the bottle jack under the vehicle with low clearance and use the lifting handle to lift it up to a desired height, but you do not work under the vehicle until another means of support, such as axle stands.

Use vehicle support stands, these Hydraulic Bottle Jacks enable you to replace the car accessories and perform routine maintenance more safely and efficiently. And complied with the EC Machinery Directive, GS and TUV approved, they have high quality. The hydraulic bypass prevents two stage ram over travel and automatic oil bypass preventing overextension of ram and prevents damage to the Jack. This is a great jack to keep nearby for emergency repairs, changing tyres on your off-road vehicle can become a very cumbersome experience if you find yourself without the proper equipment, with this Hydraulic Bottle Jack you will have your tyres changed and on your way in no time at all. A powerful heavy-duty bottle jack can lift loads weighting up to 50t. With a lift range to 150mm and equipped with the screw lift fully extended/screw extension for adjustable lifting heights to suit different situations, it allows easy loading of vehicles beyond the range of a standard bottle jacks.

They are also named heavy duty industrial hydraulic bottle jacks, double ram bottle jacks, double ram hydraulic bottle jacks with safe valve, two stage bottle jacks, hydraulic lifts, car bottle jacks, universal car repair portable mini vertical hydraulic jacks, low profile hydraulic bottle jacks and others

They are widely applied in heavy lifting and repairing in automotive, industrial sites, machinery, agriculture, mining, oil field, bridges, construction industry, garage, workshops, body shops, railway workshops, power plants, mechanical works, carpentry, farms, cramped areas and under toughest conditions, mobile homes and job sites. These models are great for applications and are very suitable for many different lifting and pushing applications that require monitoring of applied pressure. Jacks can get the heaviest of loads into the air with less effort & easier and out of the way so you can make the repair and move on to other projects, like changing the tyres on cars, SUVs, vans, ute,4WD, trucks, and trailers or make repairs to your tractor, combine or hay baler even tough and daily use.

1. Construction

Hydraulic bottle jacks adopt sturdy, strong, wide, durable, rugged, reinforced, ductile and automatic welded all-steel construction. With high quality cast malleable iron housing-- #45 hard-cast steel with heat-treated critical stress, they provide stability and reduce metal fatigue for the sake of durability. The durable Lead-free, baked enamel finish is applied after a thorough chemical wash to ensure a long-lasting finish will make it a long life time for rust resistant(rust-free) and corrosion resistant, flexible in extreme conditions as well. Paint (Electrostatically painted) is oil, grease and dirt-resistant and easily to cleanup

Heavy Duty Hydraulic Jacks are designed using supreme quality carbon and steel at our unit under the supervision and guidance (vigilant eye) of experts. State of the art design reduces repair time.

2. Base/saddle

They use unique base forging method automatic welding increasing resistance to high pressure. Casing, cylinder and lightweight large base are joined by electric welding for greater strength and are leak proof.

Stable, cleated steel lift, serrated, heat treated, heavy duty, adjusting notched saddle is designed for generous lifting area and secure grip (grove teeth effectively grip the load and prevents slippage). The strong base also provides the safest operator conditions. Models with bevelled base offer increased stability and safety as the jack follows the tilt of the vehicle when lifting, the ductile cast-iron base (Carbon steel) which is wide enough to provide the required stability during operation and will never topple over when subjected to any load capacity within the recommended range too, It with threaded components for easy disassembly.

3. Drain valve

Special automatic integrated safety overload, unique cross-type forged release valve (pre-adjusted) assures positive load control, protects the hydraulic system from overload damage (guard against overloading) and allows the handle to remain in the upright position when used horizontally, release valve assemblies and other interchangeable parts allow quick repairs, reduce the chances of breakage and excessive wear. Needle valve allows you to control the lowering of the ram (Needle valve and tapered seat release assembly allows precise control or jack ram return)

4. Brake

Automatic load brake is equipped in case of the emergency and can make instant brake when there is a need for stop.

5. Sealing ring

6. Extension screw (cap)

Convenient and heat treated extension screw allows for low pickup height adjustment and maximum lift height, spindle extension offer optimum use of the stroke and this design guarantees a smooth operation.

It allows easy loading of vehicles beyond the range of a standard Hydraulic bottle jacks. Owing to the heat treatment, adjustable extension screw with cleaned lift saddle prevents slippage (cleated/non-slip) and adds more 6 cm. It also is equipped with standby up valve.

7. Ram & plunger (piston)

The hardened, machined, polished and chromed alloy steel ram and plunger can work smoothly, resist skiving and protect rust. Double guidance plunger ("Parkerized" pump piston) made of one piece for maximum strength and resists corrosion and extends life, Piston-ram utilizes a Y-Style polyurethane sealing ring with backup ring, preventing load from falling slowly or bypassing oil drift. Raise the piston rod.

8. Handle|Double pressure bar

It comes with two-piece solid Long steel lifting handle makes for easy use and extra leverage in tight spaces and compact storage, galvanized (zinc plated) pump handles for easy storage, this handle provides maximum results with minimal effort. Lifting handle is sectional and connects quickly making storage easier, its normal length is 16 cm (altogether 28 cm long if the two handles are jointed).

9. Protect cylinder

Cylindrical shafts are driven by high performing hydraulic power packs. Machined and polished cylinders (precisely crafted) with die-cut threads ensure straight lifts preventing uneven wear, provide non-abrasive (protect seal from abrasion) leak-free, durable performance. High quality, large diameter, hydraulic steel cylinder unit resulting in lower oil pressure needed to raise the load, which helps to reduce wear and extend service life.

10. Wedge

11. Safety oil by-pass system

Integrated safety oil by-pass system prevents the ram from being overextended (prevent over travel of ram) and causing damage to the cylinder (hydraulic system is protected from internal damage), protects against over-pumping for safer operation.

12. Ratcheting heads

Safe ratcheting heads prevent slippery in order to ensure safety.

13. Non-slip

The design of non-slip equipment reduce the risk of slipping

14. Pump core

Pump core has experienced moooth polished

Others

1. 100% factory tested for reliability and safety to meet safety standards and tested to over 150% of rated capacities

2. Package

Hydraulic bottle jack with safety valve x1

2Pc jack handles

English Instruction x1

Inner packing: Color Box or Blow/Plastic Box.

Outer packing: Standard Export Carton Box.

Our Hydraulic bottle jacks are packed in industrial grade packages that are recyclable and provide protection to the products from physical and chemical damage. Additionally, the product is properly labeled to provide information. Bulk as well as retail order of the product can be fulfilled by us with ease. In addition, we guarantee to make delivery as per schedule. below is site photo of Cardboard box packaging

3. Operation Instructions

①Lifting up:

Drive the release-valve clockwise until it's very tight with the end of the thicker handle that has two notches.

②Lowering down:

Use the same end of the handle as above to drive the release-valve anti-clockwise slowly and slightly for safe lowering.

In the operation of the Hydraulic bottle jacks, at first, install the handle in oil return valve and clockwise tighten oil return valve, secondly, anticlockwise turn adjusting bolt and install handle in pump body Then operate handle up and down until vehicle leave ground. Third, install handle in oil return valve and anticlockwise tighten oil return valve. At last, anticlockwise turn adjusting nut until to the lower position.

Caution

①Do not incline it when working and overload the jack beyond its rated load is forbidden

②Before operating, estimate the weight of the load

③Select point of action according to the gravitational center and place the jack on the hard ground if necessary, place a hard plank under the jack so as to avoid tottering or falling during operation.

④Base of jack should always rest on a firm, level surface

⑤Never work under the lift load without additional support device

⑥Always read users’ manual before operation

⑦Do not get under vehicle that is supported only by a jack.

Site photos of Hydraulic Bottle Jack - 2 TON, 4 TON, 8TON, 20 TON delivered to Brazil

Inquire about mechanical bottle jacks and screw jacks from Malaysia

Looking for Hydraulic Bottle Jacks 3T, 5T, 8T, 10T, 12T, 16T, 20T & 32T from Hongkong

Model | Capacity (t) | Min H. (mm) | Lift H. (mm) | Adjust H. (mm) | Max H. (mm) | Body Dia. (mm) | N.W/PC (kg) | QTY/CTN (pcs) |

HBJ02 | 2T | 148 | 80 | 50 | 278 | 51 | 2.2 | 10 |

HBJ03 | 3T | 175 | 110 | 60 | 345 | 60 | 2.5 | 5 |

HBJ04 | 4T | 180 | 110 | 60 | 350 | 60 | 3 | 5 |

HBJ05 | 5T | 185 | 110 | 60 | 355 | 70 | 3.8 | 5 |

HBJ06 | 6T | 195 | 125 | 60 | 380 | 70 | 4 | 5 |

HBJ08 | 8T | 200 | 125 | 60 | 385 | 75 | 4.8 | 4 |

HBJ10 | 10T | 200 | 125 | 60 | 385 | 80 | 5.2 | 4 |

HBJ12 | 12T | 210 | 130 | 60 | 400 | 89 | 6.3 | 4 |

HBJ15 | 15T | 225 | 135 | 60 | 420 | 95 | 7.3 | 2 |

HBJ20 | 20T | 235 | 145 | 60 | 440 | 114 | 9.6 | 2 |

HBJ30 | 30T | 255 | 150 | 60 | 405 | 121 | 11.5 | 2 |

HBJ32 | 32T | 255 | 150 | 60 | 405 | 121 | 12.5 | 2 |

HBJ50 | 50T | 255 | 150 | 60 | 405 | 140 | 20 | 1 |

-

Cargo Trolley is an alternative to traditional with roll arounds handling equipment for handling tools. Applica…...

-

Hydraulic toe jacks are designed to lift heavy machinery and other similar type loads when there is a fair amou…...

-

Screw jack is powered by human through screw pair drive, screw rod or nut sleeve as the jacking part As a commo…...