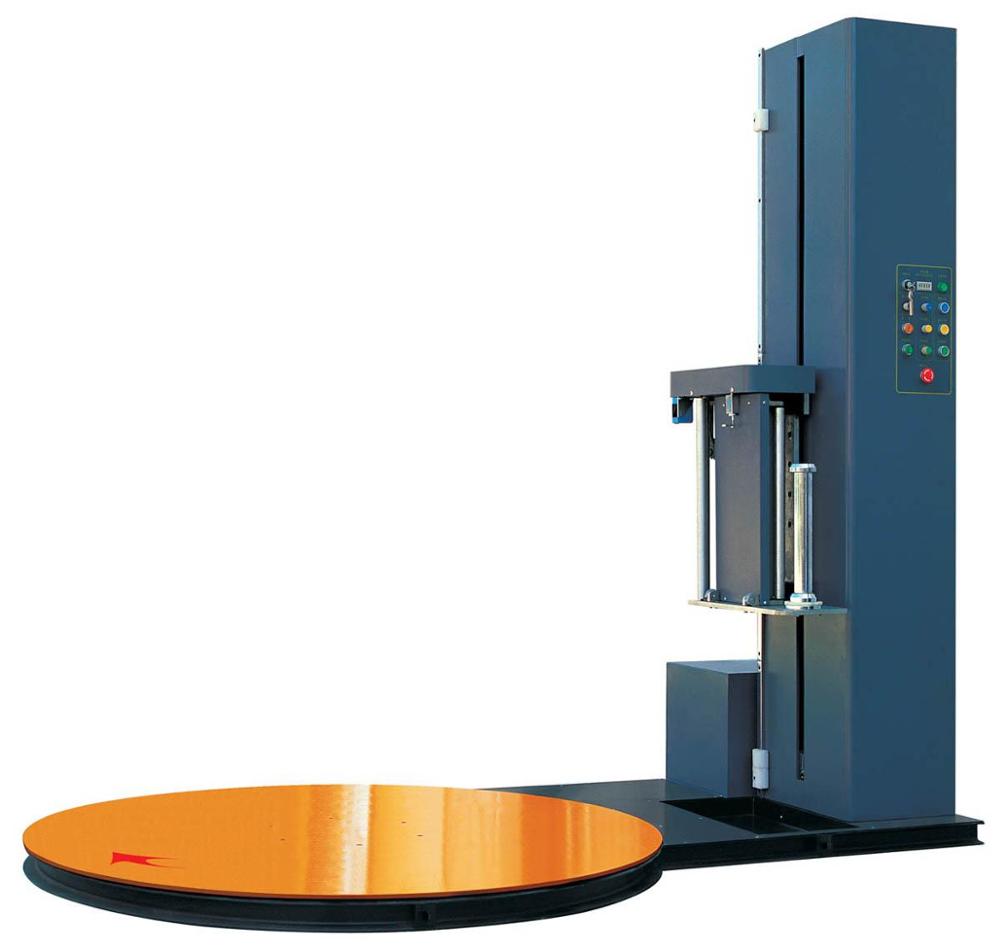

Wrap machines are wrapping machines which use LLDPE stretching film (a plastic film) as the main packing material. The stretching film is capable of providing extra support for the products while they are being transported or stocked, preventing them from spilling, tipping, or damaging. they are also called stretch wrap machines or pallet wrap machines.

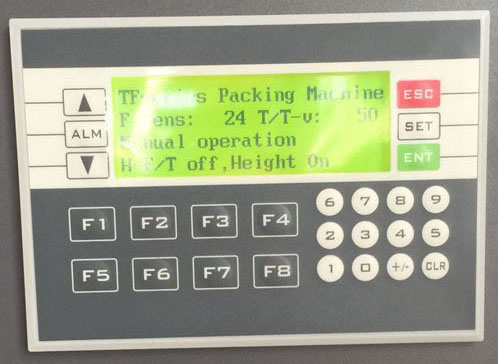

• PLC Microcomputer programmable control as well as intelligent human-computer interface

• LED display screen, pre-stretch system 300%, as well as Selected electrical control components

• High tensile strength, transport structure, high reliability, long service life, no noise and no fuel

• High efficiency, low consumption, easy operation as well as almost no daily maintenance

• The whole packaging process is able to be completed by simply pressing the run button

• Adjustable film lifting speed and film feeding speed, and follow-up film system mechanism

• International panel icon, single strength control button, and automatic /manual switch

• Photoelectric switch is used in order to measure the height of the goods automatically

• Frequency control is adopted to avoid the goods fall down that is caused by inertance

• The tension of the film can be adjusted according to the characteristics and users’ needs

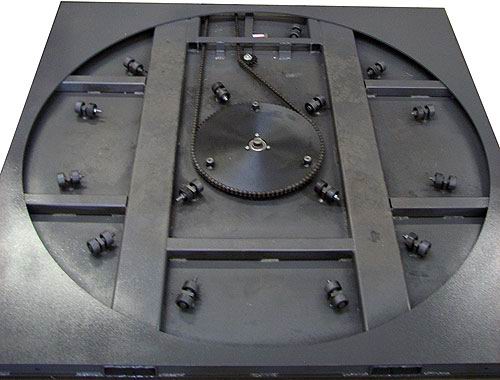

• Turntable is soft start and slow stop and operation can be conducted by hand or itself

• The double chain structure is capable of making the operation stable as well as reliable

• Winding layer and winding number are adjustable and speed of up-down is frequency adjustable

• The reinforced wrapping function is able to provide special protection for certain parts

• The turntable drive adopts the chain drive, has accurate positioning and can automatically reset

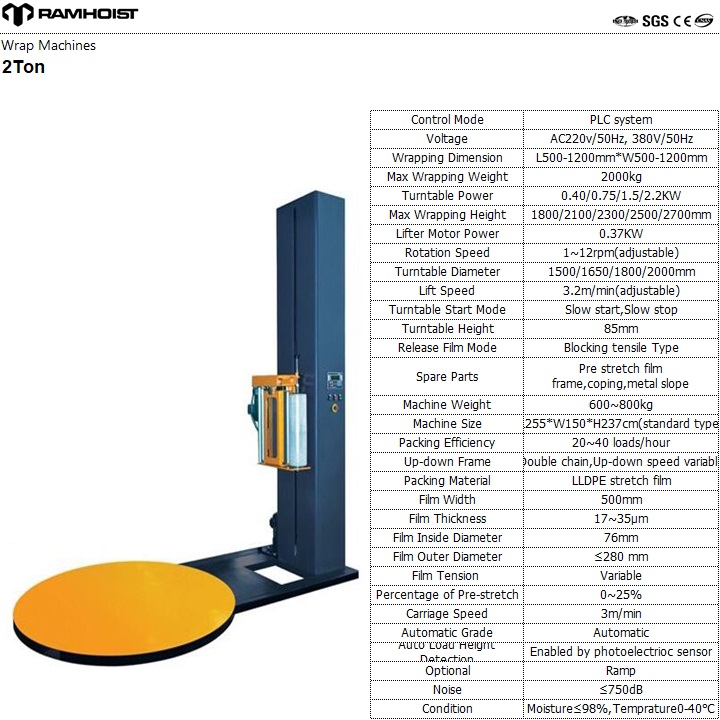

Item Wrapping machine

Voltage 220v, 50Hz

Power 1.5Kw

Weight 600~800Kg

Packing Material Plastic, stretch film

Driven Type Electric

Automatic Grade Automatic

Application Food, beverage, commodity, medical, chemical, textiles

Speed 1~12rpm (adjustable)

Packaging Type Cartons, pallet

Warranty 1 year

Lift Speed 3.2m/min (can adjust)

Control Mode PLC Microcomputer control

Condition New

Certification CE, ISO

Max Wrapping Weight ≤2000KG

After-sales Service Engineers available to service machinery overseas

Turntable Height 85mm

Lifter motor power 0.37Kw

Wrap Machines are equipment which use LLDPE stretching film (a plastic film) as the main packing material. The stretching film is capable of providing extra support for the products while they are being transported or stocked, preventing them from spilling, tipping, or damaging. Thus, wrap machines are the ideal equipment for modern enterprise product packaging and are widely used in foreign trade. Also, They are suitable for many more areas which are in need of reliable and stable packing.

By virtue of the advantages of nerviness and autohension of the stretching film, wrap machines is good at fix the goods and pallet together. So the goods never fall down or bale off. Wrap machines can pack different shape goods and the goods is easy to carry after being wrapped with pallet, which makes them suitable for industries exporting goods in huge volumes.

These wrap machines have the advantages of high security, fast packaging speed, wide packaging range and etc. Besides, they are easy to operate by hand or by the machines themselves. They can also save labour cost and working time and thus improve work efficiency. Apart from the benefit of in time taken for loading and unloading, the use of plastic film can effect clarity of goods for customs-inspection. That’s why wrap machines are well popular among exporters and importers. Package by these machines is moisture proof and dust proof and the grade of products can be improved. With the application of these wrap machines an easier recycle of the packing materials will be conducted so a less polluted environment is ensured. In fact, this is currently one of the most welcomed environmental-friendly packing methods.

These pallet wrap machines use PLC Microcomputer programmable control, intelligent human-computer interface as well as LED display screen. So they are highly electric and intelligent. With the automatic grade reaching automatic, they are extremely convenient to operate. Just press the run button and the whole packing process will be completed. By adopting a photoelectric switch, the height of the goods can be measured automatically. They have a long service life and generate no noise when working.

The extensive application of industrial stretch wrap machines has covered chemical industry, electronic industry, building materials, home appliances, paper making, foodstuff and drink etc. Especially, wrap machines suitable for container goods transportation in foreign trade because packages by them can protect the goods from damaging during long-distance transport and keep the goods staying in a good storage condition.

They also called Pallet strech wrapping film wrap machines, Case packing machines, Automatic pallet shrink wrap machines, Stretch wrapping machines, Electric pallet wrappers, Stretch film automatic stretch wrap machines for pallet wrapping, Pallet wrapping machines, Automatic pallet stretch wrap machines, Stretch film pallet wrappers, Wrapping packing machine and Case pack wrapping machines etc.

1.Independent Motor

These wrap machines use independent motors which are helpful in effecting stability of the machines and making no noise.

2.LLDPE Stretching Film

LLDPE stretching film is the main packaging material of these wrap machines. This film is suitable for different shape goods and can protect the goods from moisture and dust. Besides, the stretching film is capable of providing extra support for the products while they are being transported or stocked, preventing them from spilling, tipping, or damaging. The tension of the film can be adjusted according to the characteristics and users’ needs.

3.LED Control Display

These wrap machines are equipped with LED display screens, so they are convenient to operate for consumers.

4. Emergency Stop Button

There is an emergency stop button installed under the LED control display, which is critical to protect the products being packed and the machines themselves when something emergent happens. Just press the emergency stop button, and the machine will stop.

5.PLC Control System

These wrap machines adopt PLC control system which is more advanced and intelligent. A PLC, i.e. programmable logic controller is a computer control system used in industry to continuously monitor the input devices and make decisions based on a custom program to control the output devices.

6.Internal Frequency Converter

Frequency converters are power conversion devices which can transfer fixed frequency and voltage into variable frequency and voltage. Equipped with an internal frequency converter, these wrap machines are able to adapt to different voltages.

7.Chain Driven Turntable

The turntable which starts softly and stops slowly is driven by chain and can be mounted in all positions and has accurate positioning, Also, the turntable is able to effect accurate position and reset automatically. There’s a turntable start button to start the turntable. The weight capacity of the turntable is 2000kg and the rotary speed is adjustable from 1 to 1 round per minute.

8.Ramp

A ramp can be installed which is more economical.

9.Stainless Steel Structure

The stainless steel structure of these wrap machines can ensure them to run safer and more stable.

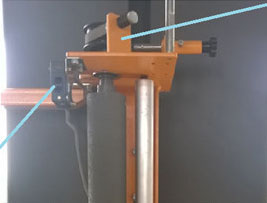

10.Tensioner

As a device that applies a force to create or maintain tension, the tensioner is used in these wrap machines to ensure the tight package by the stretching film. The tension of the film can be adjusted according to the characteristics and users’ needs.

11.Column

As the main part of the wrap machines, the columns to which the tensioners are connected are stable enough to make sure that these machines work safely.

12.Photoelectric Switch

Photoelectric switches or photoelectric eyes are devices used to control the power to a connected appliance or fixture by measuring the light which falls on the lens. In these wrap machines, the photoelectric switch which is installed on the top of the tensioner is used to measure the height of the goods automatically. It is both intelligent and accurate.

13.Turning Frame

The turning frame is connected with a limit switch to let the machine stop when it touches the ground or something, which is safe for the film head and operator.

14.Auto Start

The automatic grade of these wrap machines have reached automatic, meaning that the operation is very easy. Users only need to press the run button, and the whole packaging process will be completed automatically by the machine.

15.Double Sensing Device

A double sensing device is adopted to control the rising height.

Others

1.Pre-sale Services

① Such presale services like making investment budget, manufacturing and planning are provided for customer to make a reasonable and cost saving plan.

② Customers’ goods and goods size are checked in ahead to recommend the 100% suitable wrap machine.

③ Machines are recommended and offered according to customers’ use and purchase budget.

2.In-sale Services

①Photos of each manufacturing step are offered to customers for their in-time check.

②Packing and shipment are prepared according to customers’ requirements in advance.

③The machine will be tested and a video will be made for customers’ check.

3.After-sale Services

①The machine quality is guaranteed for one years.

②Free training are provided and customers’questions on technology will be answered in time.

4.Packing and shipping

When shipped by FCL, these wrap machines are packed by steel pallet and stretching film. When packed by LCL, they are packed by wooden box.

Notes

①Never make any temporary wire or co-wire with other devices.

②When making connection, check the live wire neutral wire and ground wire.

③Properly operate the wrap machines to effect longer service life.

④Check and maintain the machines regularly to ensure safety and stability.

Technical details of pallet wrapping machine

Technical specification of Automatic Pallet Wrapping Machine 1800mm Turntable diameter, 220V,50Hz

User Manual of Pallet Wrapping Machine

Offer of Pallet wrapping machine for Jordan

Technical parameters of Automatic wrapping machine, Automatic membrane breaking and film loading

Problem summary for Wrap Machine

Workshop of Pallet Wrapping Machine

Offer of Pallet wrapping machine for Jordan

Technical specification of Automatic Pallet Wrapping Machine 1650mm Turntable diameter, 110V, 60Hz

-

Cargo Trolley is an alternative to traditional with roll arounds handling equipment for handling tools. Applica…...

-

Hydraulic toe jacks are designed to lift heavy machinery and other similar type loads when there is a fair amou…...

-

Screw jack is powered by human through screw pair drive, screw rod or nut sleeve as the jacking part As a commo…...