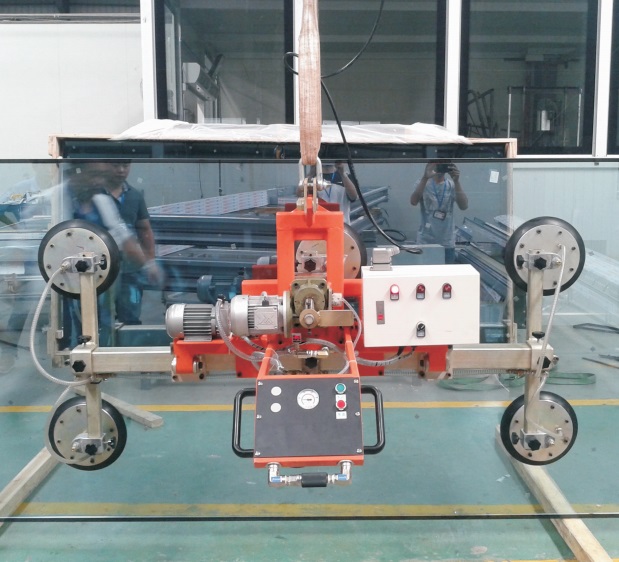

Introduction of Vacuum System (vacuum glass lifter)

Keyword:vacuum glass lifter Time:2019-11-5 10:39:28

After starting the vacuum system, the whole operation process can be fully automatic controlled. In operation, vacuum system Vacuum degree (i.e. the average distribution of vacuum thinning degree) in medium and small vacuum systems and small vacuum systems always fluctuates up and down in their allowable range, and its fluctuation range can be adjusted according to user's requirements. The optimum process can be achieved by using screw vacuum pump, Roots vacuum pump, rotary vane vacuum pump and water ring vacuum pump vacuum system. When the first vacuum pump fails to reach the required vacuum after starting, the second vacuum pump starts to reach the set vacuum value. When the required set value is reached, the first vacuum pump stops and the second vacuum pump stops circulating. The vacuum system of our company can automatically control the system without operation, and automatically close the vacuum system when power failure occurs. At the same time, the control box can protect the vacuum pump motor from overload and short circuit. Start the system, the main vacuum pump set starts to work until the vacuum degree in the vacuum tank reaches the set upper limit, the vacuum pump stops running automatically, and the vacuum in the central vacuum system is maintained by the vacuum check valve on the pipeline automatically. If the vacuum in the vacuum tank decreases and falls below the set lower limit, the standby vacuum pump set will start automatically. As a result, the vacuum degree of the vacuum system can maintain a stable vacuum source and meet the production requirements.

Applied industries: electrician, textile, CNC engraving machine, vacuum moulding machine, folder, blasting machine, computer, semiconductor application, circuit board, battery, capacitor, binding machine, photo plate maker, refrigeration and air conditioning process vacuum, packaging machine, transformer, optical lens, automatic injection, polyurethane process, label sticker, etc. Printing machine, PCB vacuum elevator, vacuum glass lifter, printing machine, VCD&DVD disc surface vacuum sputtering, industrial furnace, smelting and heat treatment, metal vacuum coating, vacuum welding, electron beam welding, vacuum coating, vacuum dry welding, vacuum packaging industry, space simulation, scientific research field, hospital negative pressure system, environmental protection Industry, electronics industry, laboratory, plastic industry, general machinery, glass, marble, vacuum handling of heavy metal and other industries.

Selection criteria for glass lifters

The following are more detailed selection criteria:1.Calculate and determine the relevant physical parameters 2.friction coefficient 3.Calculation of suction 4.Chuck diameter Inhale 5.Shape of vacuum glass lifter

Vacuum chuck has three basic shapes: 1.Flat glass lifter 2.Corrugated glass lifter 3.Chuck with special working principle 4.Correct selection of material for glass lifter

Use conditions and working environment are important factors in choosing suction cup materials. For example, for food industry, the material of suction cup should be wear-resistant, oil-resistant and stable.

Glass lifter Material Table and Material Selection Assistant: 1.Technical parameter description 2.An Example of Calculating the Diameter of Glass lifter 3.Description of shape and type of glass lifter

- No information

-

1. Design objective of electronic crane scale network management. (1) Adopt advanced distributed data processing techno…

-

Electronic crane scale bearing platform installation to focus Electronic crane scale can be installed generally on the li…