What is the end truck of the overhead crane?

Keyword:end truck Time:2018-12-1 19:05:44

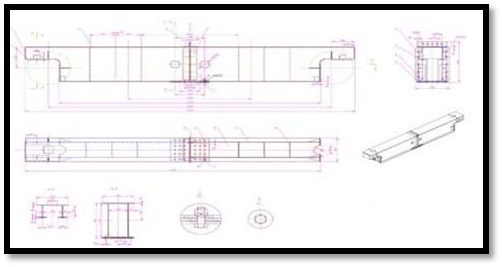

Overhead crane end truck

The installation of end truck (also called end carriage) in the crane is a very special and important part, which is used to support the bridge to maximize the stability of the overhead crane (bridge crane), It is made of new innovation material of Q235B steel.

The end truck for overhead crane is very important. It is responsible for load shifting in operation and is a key part of the whole overhead crane. Wheels and end beams are part of it. The upper cover plate, the web and the lower cover plate comprise of the end beam, which has a connecting plate and an angle steel for reinforcement. The internal installation of the overhead crane's end frame should be strengthened to improve the stability of the end beam. In the design of overhead traveling crane, the size of the end truck should be designed according to the size of the main girder, wheelbase and wheelbase of the trolley. When carrying out the installation of overhead cranes, the end truck are usually connected to the main girder and then connected to the connecting points of both ends of the beam.

As an important force component of the overhead crane, the crane end truck can gnaw the rail due to its manufacture, installation and improper operation. It needs to be maintained regularly during use.

Common crane end truck (end carriages) problems

The main reason for the wheel gnawing is the deformation of the end truck. Once the end truck is deformed in the horizontal section, crane bridge will deflect during the operation. The main beam and end frame will weld joint in the manufacturing, which will relieve the deflection degree. The principle is that the main beam of the weld is connected more. When the overhead crane is installed and welded, the end truck will bend outward because of the uneven force, reducing the deflection phenomenon.

The increase plate can be used when making the end frame, and its purpose is to increase the rigidity of the wheel installation position. In the dusty environment, there is a gap between the wheel and the machine, and the maintenance work is not in place, environment as high humidity or corrosive gas may corrode the plywood, If the plate thickness continues to decrease, the wheel will be skewed when running, resulting in serious rail biting.

- No information

-

1. Design objective of electronic crane scale network management. (1) Adopt advanced distributed data processing techno…

-

Electronic crane scale bearing platform installation to focus Electronic crane scale can be installed generally on the li…