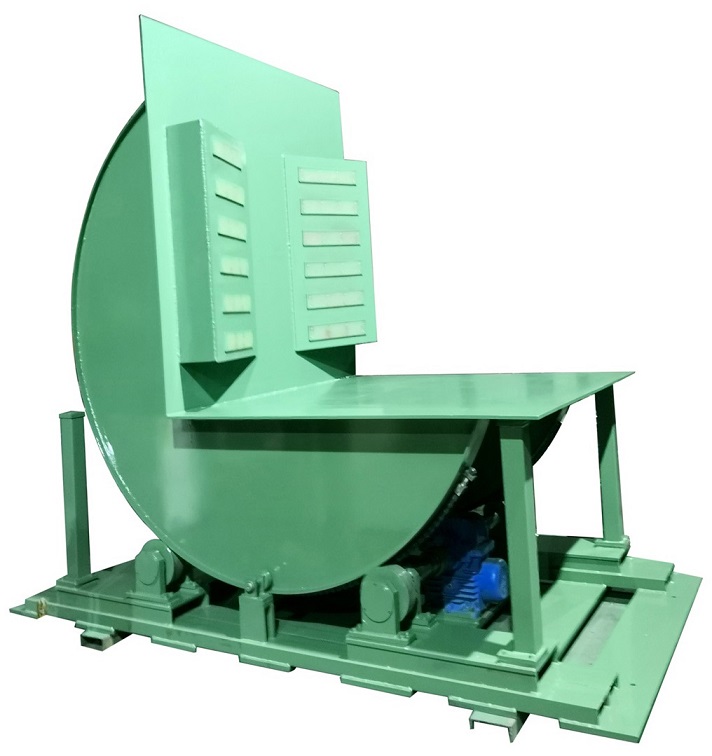

Coil upenders with multiple position systems and protective guardrails are designed as one kind of flexible handing equipments mainly used for heavy industries, which work in a way that turning over the heavy articles such as moulds, metal coils, aluminum coil, steel coils, etc from one side to another. sometime people also call it steel coil upender or coil upender handling systems.

• Wide variety of hooks and connects with shortening clutches available

• Mechanical structure, motor drive, integrated control, easy operation

• Multiple position systems and protective guardrails guarantee security function

• Manufacturing double chain drives, oblique gears and worm speed reducers under strict control

• Sound and light is produced under an alarm device whenever the job isn’t normal

• With an adjustable mechanical pressure device offering and keep in turning with energy

• Protected automatically with the over-current protection once beyond the maximum tolerance

• Smart and separate control panels allow remote operation and avoid damaging the motor

• Machines can be stopped randomly with holding device and objects will stay in current location

• Four-curler device packed with polyamide adhesive for heavy creating

• Inverter controls are adopted for high speed, stability and safety

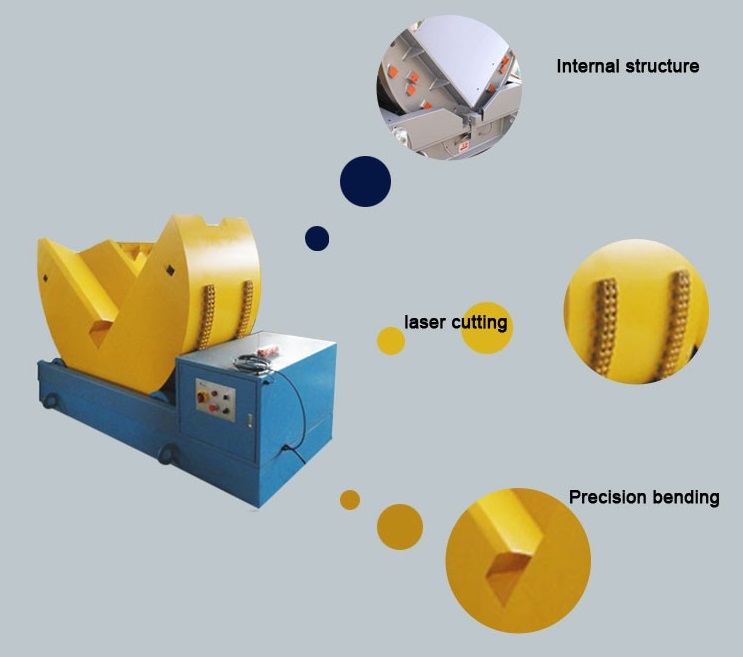

• Unique technicians adopted and colours can be customized to meet customers’ requirements

• Widely used in industries of metallurgy, stamping, barrels and etc for turning over 90 degrees

• The lines of over-current, overload and short circuit develop with the air switch of SCHNEIDER

• Decent price with competition under the high quality and on-time delivery with great package

• 12 months warranty granted on our top-than-ever commitment to customer

• Powerful quality with professional technology and certification from CE and ISO9001

Capacity 1ton-50ton

Material Metal, carbon steel

Color Blue, green, as required

Power voltage AC/380v

Power 1.5kw-7.5kw

Transfer mode Electric, double chains, four rollers, manual switch or remote switch

Working mode Automatic, semi-automatic, remote control

Flip angle 90 degrees

Ratio 1:286

Weight 1000kg-5000kg

Turn-over speed 35±10%m/s-120±10%m/s

Packaging type Cartons, film, wooden case

Packaging material Plastic, metal

Certificates CE, ISO, SGS, CNAB & ANAB standard

Warranty 12 months long guarantee

Application Apparel, beverage, commodity, food, textiles, steel industry

HS code 84289090

Coil upenders have different driving types, such as mechanical type driving and hydraulic type driving. With regard to the mechanical type driving, it is thought as the most popular type designing in market. In procession of work, upenders and tilters are drived by motors and gears with chains, which is an easy and realiable maintaining designing. Turning to the hydraulic type driving, it is used to handle the heavy duty with fast speed to ensure the safe operation thanks to the hydraulic station and cyclinder. In addition to the two driving types above, it is our great pleasure to provide customized tilters and upenders to help users solve the heavy loading handing where the load can be steel coil, mould, car, template, board and so on. We go all customized solutions per your need.

The steel coil upenders’ machine body is equipped with multiple position systems for effective underground work and is able to save space to a certain degree, special for heavy coils. It can be linked in full and complete automatic packaging systems holding the powered and unpowered conveyor lines, which reduce the labor working, save time, enhance working efficiency, and make sure secure produce. And in metal coil processing plants, coils should be put vertically or horizontally for coil loading. For example, metal coils are supposed to be horizontally heaped up in bell-type furnace while pipe mills need coils to stand vertically, which brings more convenience to lift up coils in vertical standing and is easier to pack standing coils by steel tapes.

They are also called steel coil hydraulic upenders, hydraulic steel coil tilters, 90 degree coil tilter machines, durable coil upenders for stainless steel coil, hydraulics coil upenders, 90 degree steel coil turnover machines, 90 degree tilter coil galvanizations, steel band upenders, coil upenders for rotation, 90 degree FZ-10 steel coil upender machine, copper coil tilter upender, aluminum coil tilters, Coil lifters Upenders, coil tipper upender, Upender tilters, coil upender handling systems, coil upender cart.

They are widely applied for metallurgy, stamping, sheet metal, mould, paper, cold storage, wire, drum, refrigeration, machinery and hardware, apparel, beverage, commodity, food, textiles, coil and other industries and turning-over of the heavy objects such as metal coils, copper coils, steel coils and aluminum coils, some situations where other types of upenders would fail, particularly through heavy industries.They are also ideal coil equipments for dislocation of goods from vertical to horizontal, or from horizontal to vertical for 90 degree or 180 degree turn-over.

1.Electromagnetic braking motor

The electromagnetic braking motor, commonly known as brakes and sluice, makes mechanical parts stop or decelerate. The braking motor is mainly composed of brake frames, brake parts and control devices. Some brakes also have automatic adjustment devices for the clearance of brake pieces. In the mechanical transmission system, it mainly plays the role of power transmission and movement control. The utility model has the advantages of compact structure, simple operation, sensitive response, reliable use and easy remote control. It is mainly matched with a series of motor. If there is outage in the switching process, the machine can automatically lock, then stall instead of leading to the invertion situation.

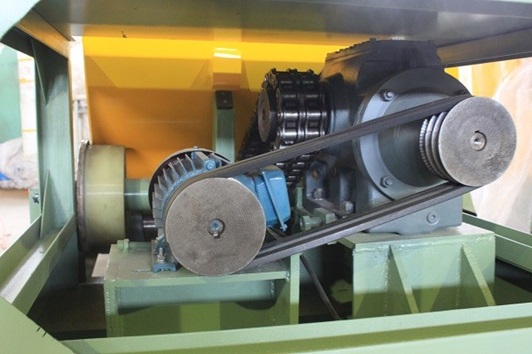

2.Cycloidal pin gear speed reducer | double row

The cycloidal pin gear speed reducer is used to reduce the speed of motor through mechanical transmission. It adopts the cycloid pin wheel for meshing and takes the place of two and three grade ordinary cylindrical gear reducer and cylindrical worm reducer. What’s more, it has been widely used in military, space, metallurgy, mine, oil, chemical, and lifting transportation. The main drive engaging parts are manufactured by bearing steel grinding. Therefore, both mechanical and abrasive resistance are good, and it has fewer failures and a longer service lifespan because of its rolling friction.

3.Bush roller chain

A roller chain is a type of chain transmission and chain drive, which is linked by a series of short cylindrical rollers and driven by a gear called sprocket. It is a simple, reliable and efficient power transfer device. When working, the inner and outer chain joints can be relatively flexible, the sleeve can rotate freely around the pin shaft, and the roller is sleeved to reduce the sign of wear between the chain and the sprocket. In order to reduce weight and make the crossing section strength equally, the inner and outer chain plates are often made into shapes of the figure ‘Eight’.

4.Bearing

The main function of bearings in coil upenders are to support the mechanical rotating body, reduce the friction coefficient during motion, and ensure the accuracy. Rolling bearings are divided into centripetal bearings and thrust bearings according to their load directions or nominal contact angles. The radial contact bearing is a centripetal bearing with a nominal contact angle of 0, and the centripetal angular contact bearing is a centripetal bearing with a nominal contact angle more than 0 to 45. The axial contact bearing is a thrust bearing with a nominal contact angle of 90, and the thrust angle contact bearing is a thrust bearing with a nominal contact angle more than 45 but less than 90.

5.Idler wheel

The idler wheel is the transmission gear between two non-contact transmission gears and meshes with the two gears to change the rotation direction of the passive gear, and it is the same as the active gear. Its function is to change the steering and not to change the transmission ratio, which is called idler wheel. Although the idler wheel transfers the force and speed ahead to the rear, it transfers the resistance of the rear to the front, but it acts according to its own meaning. Guide wheel, as the name suggests, mainly plays the guiding role in the design of the wheel system in order to meet the design requirements and the requirements of the shape size. The belt direction is more complex, but to ensure the design of the wrapping angle of the Lazer tensioner and the pulley, the steering wheel needs to be designed to follow the design package angle.

6.Clutch | Clutch switch

Clutches are small in size, high in quality, good in abrasion resistance and sufficient in heat dissipation. They are easy to operate and allow you to release by hand which is much easier to operate and not easy to break. Besides, you can manually adjust to the coil upender. Thanks to the improved clutch system, it is flexible in engaging the operation.

7.Motor

This kind serious wound electric motor is quite powerful and efficient which aims at delivering plenty of power for operation. Also, the motor has good resistance so that ensuring the durability and great adaptability.

8.Oblique gears

Oblique gears are not completely helical gears and it should be said that oblique gears are the meshing mode of the two helical gears, which are distinguished by their different directions of the space transfer force. The straight spur gear enters the meshing along the tooth width at the same time, resulting in impact vibration and noise, and the transmission is not stable. The helical cylindrical gear transmission is superior to the straight tooth, and it can tighten the center distance for high speed and heavy load. The helical gear reducer is a novel deceleration drive and it has small volume, light weight, large transfer torque, smooth starting and fine transmission ratio classification with the advanced design concept of optimization and modular combination system. Also it can be selected for arbitrary connection and multiple installation position according to the requirements of the users.

9.Tong

The tong consists of flip part and the tong. If there is a need of rotation in hoisting, the tong may be equipped with a rotating head. For the tong, motor drives screw and nut to make the tong impose initial clamping force on steel coil. After the coil is hoisted, final clamping is made by the wedge surface of tong to steel tube. For flipping part, motor drives sprocket to rotate, which drives a chain to extend and another chain to shorten, so that tong at the bottom is driven for rotation.

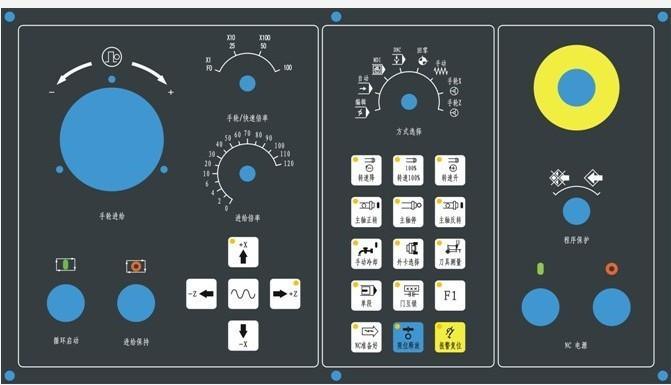

10.Control panel

Open the power needed for the operation of the Coil upenders and check whether there is any abnormal control panel. If there are any problems, contact the people concerned in time.

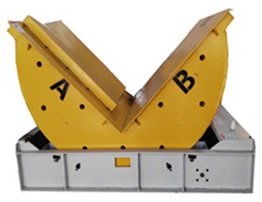

11.Four-curler device | four-roller device

The four-roller coil upenders are suitable for the bending of metal sheet. They can roll round and they are arc and conical workpieces in a certain range, and have the prebending function at the end of the plate. The remaining straight edge is small and the working efficiency is high, and the metal plate can be roughly leveled on the machine. When working, the upper roller position is fixed, and the lower roll moves straight up to clamp the steel plate. The curvature radius of the drum need to be adjusted by moving the two sides of the roller straight or arc upward. The roller movement of four-roller and three-roller bending machine is different, but the working principle is the same. They use the principle of three-point setting circle to make different rolls. But the four-roller devices’ bending straight edge and roundness of the circle should be better than that of the three-roller.

12.Inverter control

The inverter controls the adding of goods through regulate the speed of screw rod rotating.The frequency converter adjusts the voltage and frequency of the output power by the opening of the internal IGBT. According to the actual needs of the motor, the voltage of the power supply is provided, thus the purpose of energy saving and speed regulation is achieved. In addition, the frequency converter has many protection functions, such as over current, overvoltage, overload protection and so on.

Others

1.Colors

The colors are various such as black, gray, and others to meet customers’ requirements.

2.Preliminary Assembling → Welding → Post weld treatment → Spray Primer → Assembling → Paint finish → Debugging

3.After-sale service

We promised to repair the issue regardless of if it was caused by defect or misuse only if you have a problem in the first 6 months of ownership. But the 6 months repair does not cover damage caused to the upenders.

4.Configuration list

①Contactor:DELIXI- CJX2S-0901

②Disconnector:DELIXI- DZ47S C32

③Phase sequence protector:DELIXI-XJ3

④Emergency stop switch:SCHNEIDER- XB2-BS542

⑤Start button:SCHNEIDER- XB2-BA31

⑥Indicator light:SCHNEIDER- AD16-22D/S

⑦Power module:MW- S-15-24

⑧Travel switch:TEND- PR12-4DN

⑨Motor:XINRAN- R-97

⑩Connection terminal:TEND- TBR-10

5.Warranty

There is usually 12-month-warranty. Most of parts of Coil upenders can be sold seprately and we can provide some free part even if these parts are broken in expired warranty period.

6.Packaging

The film wrapping is designed for inner packaging and the outer packaging is a wood box for free fumigation. As to the packaging size, it depends on the machine you ordered.

7.Delivery time

15 days after receiving payment

8.Similar products

①180°turnover machine

②FZ-01 turnover machine

③FZ-03 turnover machine

④FZ-03b turnover machine

⑤FZ-05 turnover machine

⑥Other turnover machines

Site Photos:

Working Video of Coil Upender move on the rail (with motor): https://youtu.be/vGtQhu73Hoc

we can make the coil upender move on the rail as above or we can also select using 2 pcs universal wheels and 2 pcs fixed wheels to move.

Instruction Manual of 90 degree Coil Upender

Inquiry for 10 ton Coil Upender from U.S.

Inquiry for 10 ton Coil Upender from Slovakia

Inquiry for 10 ton Coil Upender from Malaysia

Enquiry for 10 ton Coil Tilter

Inquiry about 3 ton Coil Upender from Poland

Inquiry about 5 ton Coil Upender from Israel

Looking for small upender for coils with V-bed on one side and flat on other from U.S.

Quote for Lifting Coil Equipment 3T for UAE

Specifications

Model | Capacity (t) | Turn-over Speed (m/s) | Material | Color | Power Voltage (v) | Power (kw) | Transfer Mode | Working Mode | Dimension [L(mm)*W(mm)*H(mm)] | Flip Angle (degree) | Ratio | Weight (kg) |

CU01 | 1 | 35±5% | Metal | As required | AC/380 | 1.5 | Electric | Automatic | 2500*1100*900 | 90 | 0.240278 | 1000 |

CU02 | 2 | 35±5% | Metal | AC/380 | 1.5 | Electric | Automatic | \ | 90 | 0.240278 | 1000 | |

CU05 | 5 | 35±10% | Metal | AC/380 | 1.5 | Double chains | Semi-Automatic | 2500*1400*1600 | 90 | 0.240278 | 3000 | |

CU06 | 6 | 35±5% | Metal | AC/380 | 5 | Separated control box or Handle drive-by-wire | Semi-Automatic | 2700*1100*2100 | 90 | 0.240278 | 3500 | |

CU08 | 8 | 35±10% | Metal | AC/380 | 5 | Electric | Automatic | \ | 90 | 0.240278 | 3000 | |

CU10A | 10 | 90±10% | Metal | AC/380 | 5 | Electric | Semi-Automatic | 2500*1900*1600 | 90 | 0.240278 | 1000 | |

CU10B | 10 | 60± 10% | Metal | AC/380 | 5 | Electric | Automatic | 2500*900*1700 | 90 | 0.240278 | 4000 | |

CU10C | 10 | 60±10% | Metal | AC/380 | 2.2 | Four rollers | Semi-Automatic | 2700*1600*2100 | 90 | 0.240278 | 3000 | |

CU15A | 15 | 60±10% | Metal | AC/380 | 7.5 | Manual switch or Remote switch | Automatic | 2700*1200*2100 | 90 | 0.240278 | 2200 | |

CU15B | 15 | 80±10% | Metal | AC/380 | 3.7 | Oblique & Worm speed reducer | Remote Control | 2700*1800*2100 | 90 | 0.240278 | 4000 | |

CU30 | 30 | 120±10% | Metal | AC/380 | 5.5 | Electric | Automatic | 2700*1800*2100 | 90 | 0.240278 | 4000 | |

CU50 | 50 | 120±10% | Carbon Steel | AC/380 | 3 | Electric | Semi Automatic | 2700*2000*2100 | 90 | 0.240278 | 5000 |

-

Farm jack is a small, light weight portable jack, suitable for off-road vehicles, trucks and other vehicles in …...

-

Cargo Trolley is an alternative to traditional with roll arounds handling equipment for handling tools. Applica…...

-

Hydraulic toe jacks are designed to lift heavy machinery and other similar type loads when there is a fair amou…...